edge seal trim

Understanding Edge Seal Trim Importance and Applications

Edge seal trim is a critical yet often overlooked component in various industries, particularly in construction, automotive manufacturing, and consumer goods. Its primary function is to provide a finished edge on products, serving both aesthetic and functional purposes. This article delves into the significance of edge seal trim, its materials, applications, and the advantages it brings to different sectors.

What is Edge Seal Trim?

Edge seal trim, also known as edge banding or edge finishing, refers to the process of applying a strip of material along the edges of products such as plywood, particleboard, or metal sheets. The purpose of this trim is to cover exposed edges, which may not only detract from the overall appearance but can also compromise the durability of the item.

The materials used for edge seal trim can vary widely, ranging from wood veneer to PVC, ABS, and aluminum. Each material offers distinct advantages, making it suitable for specific applications. For instance, wood veneer provides a natural look, making it an excellent choice for furniture, while PVC is more durable and moisture-resistant, making it ideal for areas prone to humidity.

Importance of Edge Seal Trim

1. Aesthetic Appeal One of the primary reasons for using edge seal trim is to enhance the visual appeal of a product. A neatly finished edge can transform an otherwise plain item into something visually striking. In the furniture industry, for example, edge trim can mimic solid wood edges, providing a high-end look without the associated costs.

2. Protection from Damage Exposed edges are susceptible to chipping, splintering, and wear, which can degrade the product over time. Edge seal trim serves as a protective barrier, safeguarding materials from physical damage and environmental factors such as moisture and dirt.

3. Improved Durability By sealing the edges, manufacturers can significantly increase the lifespan of their products. Edge trim helps to prevent delamination in composite materials and reduces the risk of water penetration, which can cause warping and swelling.

4. Ease of Maintenance Products with properly finished edges are generally easier to clean and maintain. Edge seal trim can create a smooth surface that is resistant to dirt accumulation, making it simpler for users to keep their items looking new.

edge seal trim

5. Cost-Effectiveness While it may seem like an additional expense, using edge seal trim can be cost-effective in the long run. By enhancing durability and reducing the likelihood of damage, manufacturers can save on replacement costs and warranty claims.

Applications of Edge Seal Trim

Edge seal trim finds applications in various sectors, reflecting its versatility

- Furniture Manufacturing In the furniture industry, edge seal trim is extensively used to finish tabletops, cabinetry, and shelves. It allows manufacturers to offer a range of designs and finishes, catering to diverse consumer preferences.

- Automotive Industry In automotive manufacturing, edge seal trim plays a vital role in vehicle interiors. It is used to cover sharp edges in upholstery and dashboard components, enhancing safety and aesthetics.

- Construction Edge seal trim is crucial in construction projects, particularly in the finishing of drywall, flooring, and cabinetry. It not only improves the overall look of a space but also enhances the durability of building materials.

- Consumer Goods Various consumer products, from electronics to kitchenware, employ edge seal trim to ensure functional edges that are both attractive and safe for everyday use.

Conclusion

Edge seal trim is an indispensable element in modern manufacturing and design, offering a blend of aesthetic enhancement and functional protection. As industries continue to prioritize quality, durability, and consumer appeal, the role of edge seal trim will likely continue to grow. Whether in furniture, automotive applications, or construction, recognizing the value of this seemingly minor addition can lead to significant improvements in product quality and customer satisfaction. Selecting the right type of edge seal trim is essential for maximizing these benefits and ensuring that products not only look good but also stand the test of time.

-

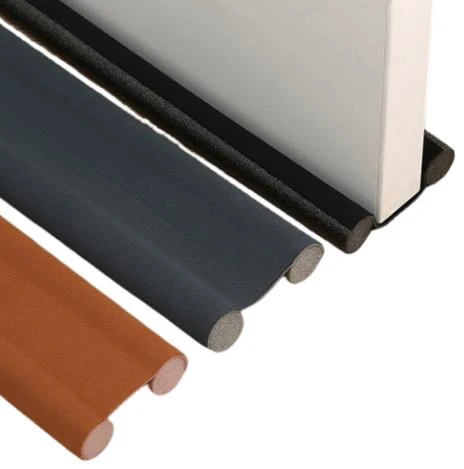

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025