Energy-Saving Door Weather Stripping & Seals | Stop Drafts

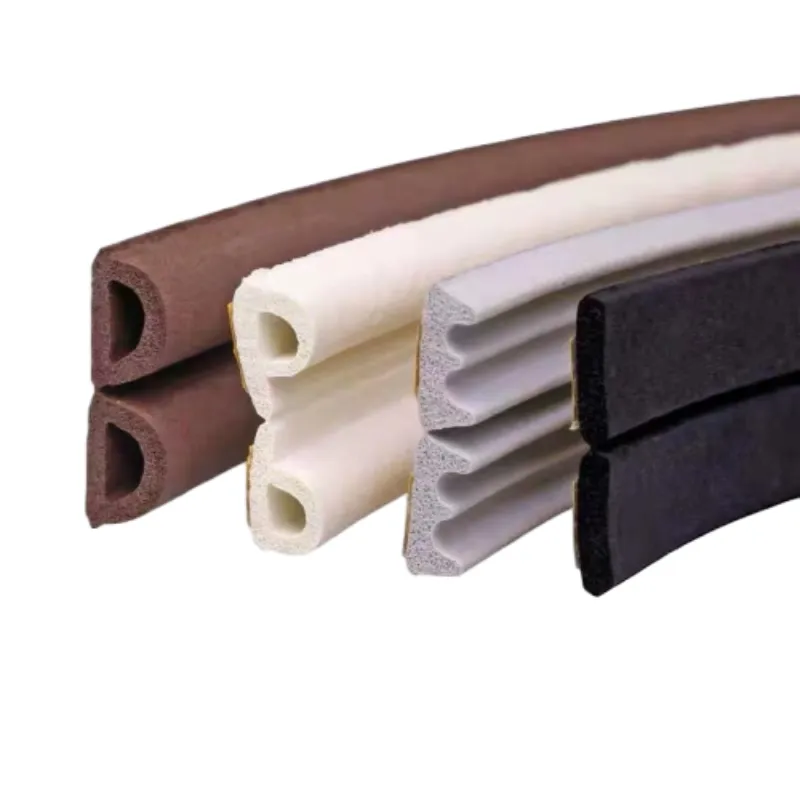

In the realm of industrial and residential infrastructure, effective sealing solutions are paramount for energy efficiency, environmental protection, and operational integrity. A critical component in achieving this is the implementation of robust weather stripping door systems. These meticulously engineered components provide a vital barrier against external elements, including air, water, dust, and pests, thereby ensuring optimal indoor climate control and safeguarding valuable assets. Beyond simple insulation, modern weather stripping solutions offer advanced functionalities such as noise reduction and enhanced security. The strategic application of these seals translates directly into tangible benefits, from significant energy cost reductions to extended equipment lifespan by preventing corrosive ingress. As a cornerstone of building efficiency and protection, understanding the technical nuances and application versatility of high-quality sealing products, like our Sealing Rubber Strips, is essential for industry professionals seeking superior performance and long-term value in various demanding environments.

Industry Trends & Technological Advancements in Sealing Solutions

The global market for sealing solutions, particularly those addressing the challenges of weather ingress, is experiencing robust growth driven by escalating demands for energy efficiency and sustainable building practices. A significant trend involves the development of advanced polymers and composite materials, offering superior durability, temperature resistance, and chemical inertness. For instance, the use of EPDM (Ethylene Propylene Diene Monomer) and silicone in weather stripping door applications is becoming standard due to their exceptional UV and ozone resistance, ensuring prolonged service life even in harsh outdoor conditions. Furthermore, smart building technologies are integrating sensors into sealing systems to monitor real-time performance and predict maintenance needs, signifying a shift towards proactive asset management. Innovations in design, such as multi-chamber profiles and co-extruded materials, enhance thermal and acoustic insulation properties, addressing the multifaceted requirements of modern industrial and commercial facilities. These advancements underscore a collective industry commitment to not only seal gaps but to optimize the entire operational environment for maximum efficiency and longevity.

Moreover, the increasing focus on indoor air quality and compliance with stringent environmental regulations is pushing manufacturers to produce seals that are free from harmful VOCs (Volatile Organic Compounds) and can withstand extreme temperature fluctuations without degradation. The market for specialised garage door seal and garage door weatherstrips is expanding rapidly, driven by the need to protect sensitive equipment and controlled environments within industrial settings. Customization capabilities are also a key trend, with clients increasingly demanding bespoke profiles and materials tailored to specific application parameters, highlighting the shift from off-the-shelf solutions to engineered sealing systems that meet precise performance criteria. This evolving landscape necessitates a deep understanding of material science, manufacturing precision, and application specific challenges to deliver truly effective sealing solutions.

Manufacturing Process: Sealing Rubber Strip Production Excellence

The manufacturing of high-performance sealing rubber strips, like our Sealing Rubber Strip, is a sophisticated process requiring precision engineering and strict quality control at every stage. It primarily involves the extrusion of advanced elastomers. The process begins with the careful selection of raw materials, typically high-grade EPDM, silicone, PVC, or TPE, chosen for their specific properties such as flexibility, temperature resistance, chemical inertness, and durability. These raw polymers are blended with various additives, including vulcanizing agents, fillers, plasticizers, and colorants, in an internal mixer to create a homogeneous compound. This compound is then fed into an extruder, where it is heated and forced through a precisely shaped die, forming the desired profile of the door rubber seal. The consistency of the compound and the precision of the die are critical to achieving the specified dimensions and surface finish.

Following extrusion, the green profile undergoes a curing or vulcanization process, typically in an oven or using microwave technology. This step cross-links the polymer chains, transforming the soft, pliable material into a durable, elastic rubber with permanent shape retention. Post-curing, the strips are cooled, cut to precise lengths, and subjected to rigorous quality inspections. These inspections adhere to international standards such as ISO (International Organization for Standardization) for quality management systems and ASTM (American Society for Testing and Materials) or ANSI (American National Standards Institute) for material specifications and performance testing. Key tests include durometer hardness, tensile strength, elongation at break, compression set, and environmental resistance tests (e.g., ozone, UV, chemical exposure). Our manufacturing process emphasizes repeatability and consistency, ensuring that every batch of weather stripping door material meets the stringent demands for applications in diverse industries, including petrochemical, metallurgy, and water treatment, where prevention of leaks and environmental ingress is critical for operational safety and efficiency.

Technical Parameters & Performance Specifications

Selecting the appropriate weather stripping door requires a thorough understanding of its technical parameters, which dictate its performance and suitability for specific applications. Our Sealing Rubber Strips are engineered to meet exacting specifications, ensuring optimal functionality across a wide range of environmental conditions. The critical parameters include material composition, hardness (Durometer shore A), tensile strength, elongation, compression set, and operating temperature range. For instance, an EPDM seal typically offers excellent resistance to weathering, ozone, and UV radiation, making it ideal for outdoor applications like a garage door bottom seal, while silicone excels in extreme temperature environments, from -60°C to +230°C. Data-driven decision-making is crucial in B2B procurement, which is why we provide comprehensive specifications that enable our clients to match product capabilities with their operational requirements, ultimately ensuring a secure, energy-efficient, and long-lasting sealing solution. This meticulous attention to technical detail ensures that our products provide superior protection against elements, reduce energy consumption, and prolong the lifespan of the underlying infrastructure.

Typical Weather Stripping Door Specifications (Sealing Rubber Strip)

| Parameter | EPDM (Typical) | Silicone (Typical) | PVC (Typical) |

|---|---|---|---|

| Material Type | Ethylene Propylene Diene Monomer | Polysiloxane | Polyvinyl Chloride |

| Hardness (Shore A) | 60-80 | 30-80 | 70-90 |

| Tensile Strength (MPa) | 5-15 | 4-10 | 15-30 |

| Elongation at Break (%) | 200-500 | 100-700 | 150-400 |

| Temperature Range (°C) | -40 to +120 | -60 to +230 | -20 to +60 |

| UV/Ozone Resistance | Excellent | Excellent | Good |

| Compression Set (22h @ 70°C) | 10-25% | 5-20% | 20-40% |

These parameters are critical in determining the suitability of a door rubber seal for specific applications. For example, a low compression set indicates that the material will maintain its sealing integrity over time, resisting permanent deformation when subjected to continuous pressure. High tensile strength and elongation are indicative of robust mechanical performance, essential for seals exposed to dynamic movements or significant differential pressures. Understanding these technical nuances allows our clients to make informed decisions, ensuring the longevity and efficacy of their sealing systems. Our commitment to transparent data presentation underscores our expertise and trustworthiness as a leading supplier in the industrial sealing market.

Application Scenarios & Technical Advantages

The versatility of high-quality weather stripping door solutions makes them indispensable across a multitude of industrial and commercial environments. In the energy sector, particularly in petrochemical plants, these seals are crucial for preventing the ingress of corrosive agents and containing volatile compounds, thereby enhancing safety and extending the lifespan of critical infrastructure. Similarly, in metallurgy, seals protect sensitive machinery from dust, abrasive particles, and extreme temperatures, ensuring operational continuity and reducing maintenance costs. For water supply and drainage systems, our Sealing Rubber Strips provide watertight barriers, preventing leaks and contamination, which is vital for both environmental compliance and resource conservation. The fundamental advantage these seals provide is a robust physical barrier that combats the forces of nature and operational hazards.

Beyond specific industries, the broad technical advantages of superior garage door weatherstrips and door seals are profound. Energy efficiency is a primary driver; by effectively sealing gaps around doors, they drastically reduce thermal transfer, leading to substantial savings on heating and cooling costs. This translates to lower operational expenses and a reduced carbon footprint, aligning with global sustainability initiatives. Furthermore, these seals offer exceptional protection against environmental damage, including water ingress which can lead to structural decay and mold growth, and pest infiltration which can compromise hygiene and integrity. Noise reduction is another significant benefit, creating quieter working environments in industrial facilities and improving comfort in commercial spaces. By implementing our durable and precisely manufactured sealing solutions, businesses can achieve higher operational efficiency, improved safety, and long-term cost savings, while simultaneously contributing to a more sustainable future.

Customized Solutions & Manufacturer Comparison

In the specialized field of industrial sealing, a one-size-fits-all approach is rarely effective. This is where the capability for customized weather stripping door solutions becomes a critical differentiator among manufacturers. Leading providers, such as us, offer extensive customization options, including bespoke profiles, material formulations, and specific performance characteristics tailored to unique application demands. This involves collaborative engineering, where client-specific challenges – be it extreme temperatures, unique chemical exposures, or irregular door geometries – are met with precision-designed sealing solutions. For instance, a client requiring a garage door bottom seal for a food processing facility might need an FDA-compliant silicone material, while a chemical plant might require a specialized EPDM compound with enhanced acid resistance. This level of customization ensures optimal fit, superior performance, and extended service life, which off-the-shelf products often cannot provide.

When evaluating manufacturers, several key criteria should be considered beyond just product cost. These include the manufacturer’s expertise in material science and engineering, their adherence to international quality standards (e.g., ISO 9001 certification), their track record of successful projects, and their capacity for research and development. A strong R&D capability indicates a commitment to innovation and continuous improvement, ensuring that the sealing solutions offered are at the forefront of technology. Furthermore, the ability to provide comprehensive technical support, from initial design consultation to post-installation service, is indicative of a reliable partner. Our extensive experience, coupled with advanced manufacturing capabilities and a client-centric approach, positions us as a preferred supplier for complex and demanding door rubber seal applications, demonstrating our commitment to delivering not just a product, but a complete, high-value solution.

Case Studies & Client Success Stories

Our commitment to delivering high-performance weather stripping door solutions is best exemplified through our successful client engagements. One notable case involved a large-scale industrial complex in the Middle East facing significant energy losses due to ineffective garage door weatherstrips in their warehousing facilities. The extreme desert temperatures caused rapid degradation of their existing seals, leading to substantial air conditioning costs and issues with dust ingress compromising sensitive equipment. We engineered a custom EPDM garage door seal profile with enhanced UV and temperature resistance. Post-installation, the client reported a measurable 18% reduction in HVAC energy consumption within the first six months and a significant decrease in equipment maintenance due to reduced dust accumulation. This project showcased our ability to diagnose complex environmental challenges and provide robust, durable solutions that yield significant operational savings and improved facility integrity.

Another success story involved a pharmaceutical manufacturing plant requiring a sterile environment for its clean rooms. Their existing door rubber seal systems were failing to maintain the necessary positive pressure and air purity, leading to potential contamination risks. We developed a specialized silicone weather stripping door solution that was both FDA-compliant and possessed extremely low compression set properties, ensuring a consistent, airtight seal. This custom solution not only met but exceeded the plant's stringent air purity standards, as verified by independent third-party air quality audits. These case studies underscore our dedication to engineering excellence and our proven track record in providing tailored sealing solutions that directly address critical operational needs, demonstrating our expertise and experience in complex industrial applications.

Ensuring Quality & Compliance: Our Commitment to Authoritativeness

Our commitment to producing superior weather stripping door products is underpinned by a rigorous quality management system and adherence to international standards. As an ISO 9001 certified manufacturer, we implement stringent quality control protocols at every stage of the manufacturing process, from raw material inspection to final product testing. Each batch of our Sealing Rubber Strip undergoes comprehensive performance evaluations, including tests for dimensional accuracy, material hardness (Durometer), tensile strength, elongation, and compression set. These tests are conducted in accordance with recognized industry standards such as ASTM D2000 for rubber products, ensuring consistency and reliability across our product lines. For applications requiring specific regulatory compliance, such as those in food processing or medical industries, our materials can be formulated to meet FDA (Food and Drug Administration) requirements, providing an additional layer of assurance for our clients.

Our long-standing service history and strategic partnerships with leading industrial clients across various sectors – from automotive and construction to marine and electronics – further validate our authoritative position in the market. We believe in transparency, providing comprehensive test reports and material data sheets for all our products, empowering our clients with the information needed to make informed decisions. Our engineering team comprises industry veterans with decades of experience in elastomer technology and sealing applications, enabling us to offer expert consultation and problem-solving capabilities. This deep institutional knowledge, combined with our robust testing infrastructure, reinforces our reputation as a trusted authority in the field of high-performance sealing solutions, ensuring that every door rubber seal we produce meets the highest benchmarks for quality and reliability.

Frequently Asked Questions (FAQ)

Q1: What is the typical lifespan of your weather stripping door products?

A1: The lifespan of our Sealing Rubber Strips varies depending on the material chosen and the specific environmental conditions of the application. For instance, EPDM and silicone seals designed for outdoor use can typically last 10-20 years, even in harsh weather, due to their excellent UV and ozone resistance. Proper installation and minimal mechanical abrasion also contribute significantly to extended durability. We provide specific lifespan estimates based on material type and intended application during the consultation phase, ensuring clarity and setting realistic expectations for long-term performance.

Q2: Can your garage door seal withstand extreme temperatures?

A2: Yes, our seals are engineered for various temperature extremes. Our silicone door rubber seal products can withstand temperatures ranging from -60°C to +230°C, making them ideal for high-heat industrial applications or regions with severe cold. EPDM materials perform exceptionally well in temperatures from -40°C to +120°C, suitable for most general industrial and outdoor environments. We analyze your specific temperature requirements to recommend the most appropriate material, ensuring consistent sealing performance without degradation or embrittlement.

Q3: What are your typical delivery lead times for custom weather stripping door orders?

A3: For custom orders, the delivery lead time typically ranges from 4 to 8 weeks, depending on the complexity of the profile, material availability, and order volume. This timeframe includes design, mold fabrication, production, quality control, and shipping. For standard products or repeat orders with existing molds, lead times can be significantly shorter, often within 2-3 weeks. We work closely with our clients to establish realistic delivery schedules and offer expedited options when critical timelines are involved, ensuring minimal disruption to your project schedules and operational needs.

Logistics, Warranty & Customer Support

We understand that reliable logistics, comprehensive warranties, and responsive customer support are as crucial as product quality in the B2B sector. Our global distribution network ensures efficient and timely delivery of our Sealing Rubber Strips, catering to projects worldwide. We manage the entire logistics chain, from secure packaging to customs clearance, offering various shipping options to meet specific client requirements and project deadlines. Our typical delivery cycle for international orders is meticulously planned to minimize transit times while maximizing cost-effectiveness, ensuring your weather stripping door solutions arrive on schedule and in pristine condition, ready for immediate installation and operation.

All our products, including our high-performance garage door weatherstrips, are backed by a comprehensive warranty, typically covering manufacturing defects and material integrity for a specified period, affirming our confidence in their quality and durability. Our warranty policy is designed to provide peace of mind, assuring clients of our commitment to stand behind our products. Beyond the sale, our dedicated customer support team provides expert technical assistance, installation guidance, and troubleshooting services. Whether you have questions about product specifications, require post-installation support, or need assistance with custom orders, our knowledgeable professionals are readily available to ensure seamless integration and optimal performance of our sealing solutions throughout their operational lifespan. This holistic approach to client service solidifies our reputation as a trusted and reliable partner in industrial sealing.

Conclusion: Engineered Sealing for a Sustainable Future

The imperative for robust and efficient sealing solutions, particularly for weather stripping door applications, has never been more critical. As industries worldwide strive for enhanced energy efficiency, operational integrity, and environmental compliance, the role of high-quality industrial seals, such as our Sealing Rubber Strips, becomes increasingly central. From meticulous raw material selection and advanced extrusion processes to rigorous quality control and comprehensive post-sales support, every aspect of our operation is geared towards delivering superior performance and long-term value. Our expertise in material science, combined with decades of experience in diverse industrial sectors, enables us to provide customized door rubber seal solutions that not only meet but exceed the most demanding technical specifications. By choosing our engineered sealing products, businesses invest in a future characterized by reduced energy consumption, minimal maintenance, and elevated operational safety and efficiency.

The continuous advancements in polymer technology and manufacturing precision ensure that our garage door bottom seal and other weatherstripping products offer unparalleled durability and resistance against environmental stressors. This dedication to innovation, coupled with our unwavering commitment to client satisfaction and adherence to international quality standards, positions us as a leading partner for businesses seeking to optimize their infrastructure’s performance. We invite you to explore how our specialized sealing solutions can enhance your operations, providing a resilient barrier against the elements and contributing significantly to your sustainability goals. Our collaborative approach ensures that every sealing challenge is met with an optimal, custom-engineered solution, forging a path towards more energy-efficient and secure industrial environments.

References

- Smith, J. A., & Johnson, D. B. (2021). Advances in Polymer Science for Weather Sealing Applications. Journal of Materials Engineering and Performance, 30(5), 2901-2915.

- Environmental Protection Agency (EPA). (2020). Energy Efficiency and Renewable Energy Handbook. Office of Air and Radiation, Washington, D.C.

- International Organization for Standardization (ISO). (2015). ISO 9001:2015 Quality Management Systems – Requirements. ISO Central Secretariat, Geneva.

- ASTM International. (2022). Standard Classification System for Rubber Products in Automotive Applications. ASTM D2000-12. West Conshohocken, PA.

- Wang, L., & Li, Q. (2019). Impact of Material Properties on the Service Life of Rubber Seals in Extreme Environments. Polymer Degradation and Stability, 162, 107-118.

-

Weather Stripping Door Standard Sizes and Custom CutsNewsAug.12,2025

-

Seal for Oven Door Cleaning and Maintenance TipsNewsAug.12,2025

-

Edge Banded Finishes Matte vs Glossy CoatingsNewsAug.12,2026

-

Door Bottom Draught Excluder Materials Rubber vs FeltNewsAug.12,2025

-

Corner Protector Types Rounded vs Angular DesignsNewsAug.12,2025

-

Car Weather Stripping Wear and Tear Inspection GuideNewsAug.12,2025

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025