Telephone: +8618730949119

E-mail: 1299343081@qq.com

Feb . 10, 2025 10:06

Back to list

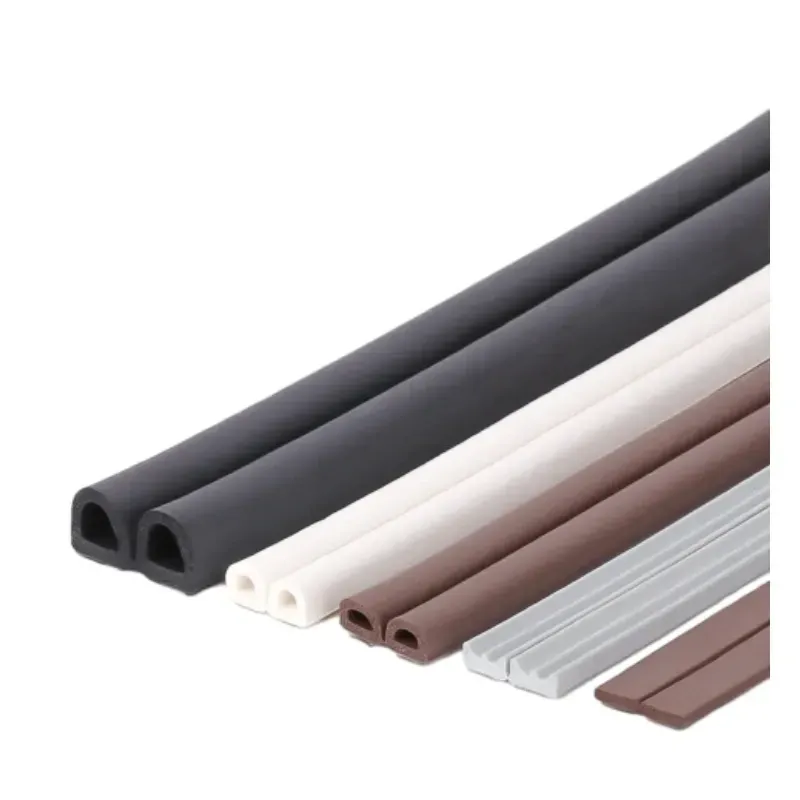

flat rubber seal strip

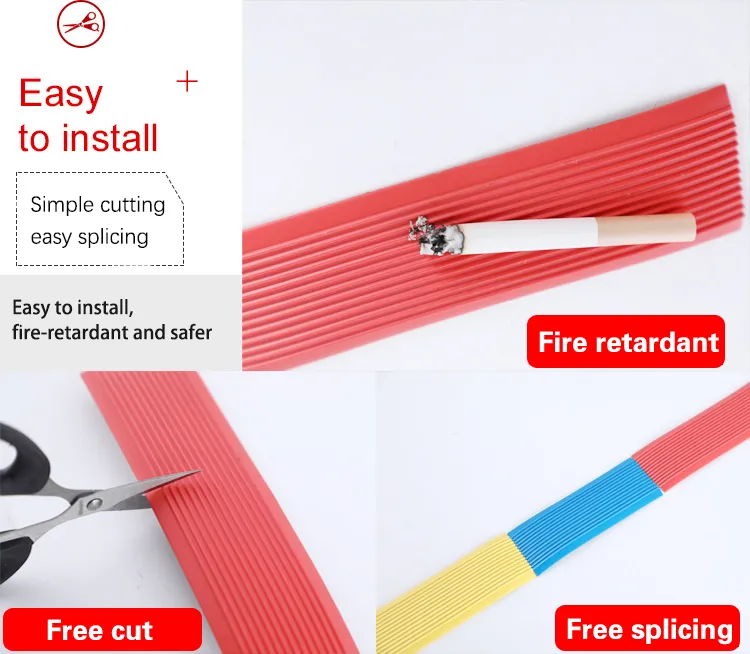

Flat rubber seal strips, although small and often overlooked, play a crucial role in ensuring the efficiency and longevity of various products and systems. From industrial machinery to household appliances, these seals serve as the unsung heroes by preventing leaks, blocking out dust, and reducing noise, thereby enhancing overall performance and lifespan.

Trustworthiness in flat rubber seal strips is demonstrated by their compliance with industry standards and rigorous testing. In my professional journey, I have consistently emphasized the importance of acquiring seals that adhere to standards such as ASTM or ISO. This compliance reassures users that the product has passed stringent evaluations and is suited for the designated application. Engaging with a reputable supplier or manufacturer who provides ample product information and reliable customer support can significantly enhance trustworthiness. Expertise in the selection and application of flat rubber seal strips extends to understanding the nuances of each operational environment and anticipating the challenges they pose. For instance, noise reduction in automotive industries can be dramatically enhanced by strategically placing flat rubber seal strips to act as dampeners. Similarly, they can be applied as insulating seals in HVAC systems to boost energy efficiency by minimizing heat transfer and air leakage. End-users often overlook the maintenance and replacement of these seal strips. An authoritative approach to using flat rubber seal strips involves periodic inspection and replacement as needed. Prolonged exposure to environmental conditions can lead to wear and tear, and preemptive maintenance can prevent costly downtime and potential damage to equipment. Summarizing my authoritative insights, selecting flat rubber seal strips involves a detailed evaluation of materials, design specifications, compliance with industry standards, and strategic application based on expertise in the domain. Such informed decisions lead to enhanced product performance, longevity, and operational savings. Whether in industrial applications or everyday products, these components are indispensable, and understanding them can significantly enhance their efficiency and durability.

Trustworthiness in flat rubber seal strips is demonstrated by their compliance with industry standards and rigorous testing. In my professional journey, I have consistently emphasized the importance of acquiring seals that adhere to standards such as ASTM or ISO. This compliance reassures users that the product has passed stringent evaluations and is suited for the designated application. Engaging with a reputable supplier or manufacturer who provides ample product information and reliable customer support can significantly enhance trustworthiness. Expertise in the selection and application of flat rubber seal strips extends to understanding the nuances of each operational environment and anticipating the challenges they pose. For instance, noise reduction in automotive industries can be dramatically enhanced by strategically placing flat rubber seal strips to act as dampeners. Similarly, they can be applied as insulating seals in HVAC systems to boost energy efficiency by minimizing heat transfer and air leakage. End-users often overlook the maintenance and replacement of these seal strips. An authoritative approach to using flat rubber seal strips involves periodic inspection and replacement as needed. Prolonged exposure to environmental conditions can lead to wear and tear, and preemptive maintenance can prevent costly downtime and potential damage to equipment. Summarizing my authoritative insights, selecting flat rubber seal strips involves a detailed evaluation of materials, design specifications, compliance with industry standards, and strategic application based on expertise in the domain. Such informed decisions lead to enhanced product performance, longevity, and operational savings. Whether in industrial applications or everyday products, these components are indispensable, and understanding them can significantly enhance their efficiency and durability.

Latest news

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025