flat rubber strips

Understanding Flat Rubber Strips Versatile Solutions for Various Industries

Flat rubber strips, commonly made from natural or synthetic rubber, have emerged as essential components across a multitude of industries. They provide a robust solution for applications requiring flexibility, durability, and resistance to environmental factors. This article explores the characteristics, applications, and benefits of flat rubber strips, revealing why they are a preferred choice for both manufacturers and consumers.

Characteristics of Flat Rubber Strips

Flat rubber strips come in a variety of widths, thicknesses, and lengths, catering to different needs. Their inherent properties, including flexibility and compressive strength, make them suitable for numerous applications. Depending on the formulation of the rubber, these strips can resist heat, abrasion, chemicals, and UV rays. Some strips incorporate additives that enhance their performance, such as anti-static properties or improved adhesion qualities.

Flat rubber strips can be produced in several styles, including solid, sponge, or reinforced forms. Solid strips are used where a firm yet flexible barrier is required, while sponge strips offer cushioning and sealing capabilities. Reinforced variants are utilized in applications where higher tensile strength is necessary.

Applications in Various Industries

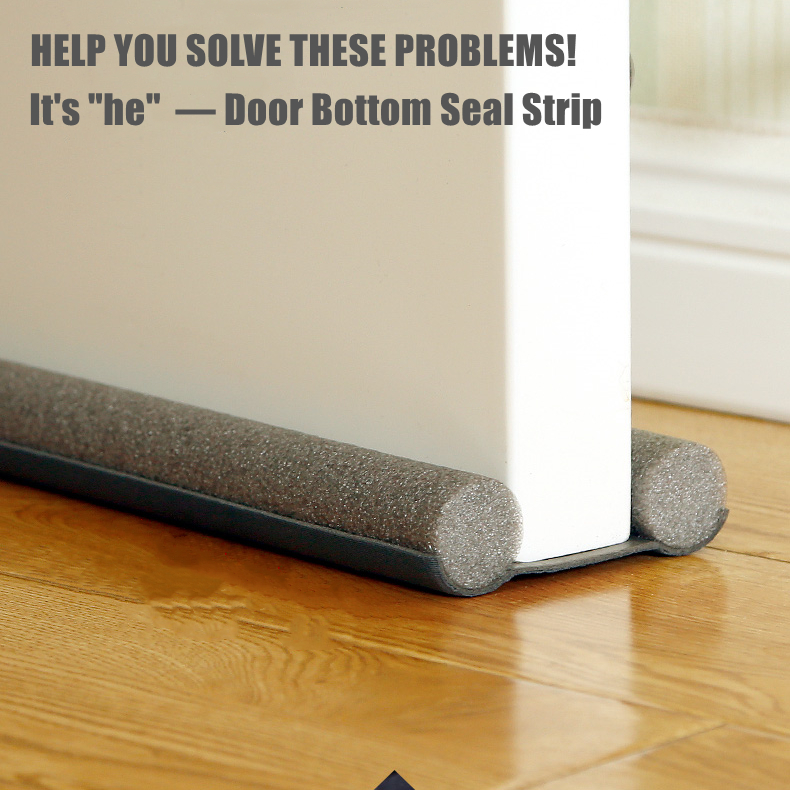

One of the most common uses of flat rubber strips is in sealing applications. In the automotive industry, they are utilized for weatherstripping around doors and windows, preventing water and air intrusion. This not only enhances the comfort of the vehicle's interior but also contributes to improved energy efficiency.

flat rubber strips

In construction, flat rubber strips serve critical roles in sealing joints between different materials, providing insulation against both sound and temperature

. They are often used in roofing systems to prevent leaks or as expansion joint fillers in concrete structures. Their ability to absorb shock and vibrations makes them ideal for use in flooring applications as well.The manufacturing sector also benefits from flat rubber strips, as they are commonly used as conveyor belt components or guides. Their durability ensures that machinery runs smoothly, minimizing wear and tear on equipment. In electronics, flat rubber strips can act as gaskets, providing protection against dust and moisture infiltration, which is vital for maintaining device integrity.

Benefits of Using Flat Rubber Strips

The advantages of employing flat rubber strips in various applications are manifold. Firstly, their adaptability makes them suitable for bespoke projects, allowing manufacturers to customize the strips according to specific requirements. Secondly, the longevity of rubber strips leads to lower replacement costs and reduced maintenance needs, making them a cost-effective solution in the long run.

Furthermore, flat rubber strips are environmentally friendly options when sourced from natural rubber. Many manufacturers are also turning to recycled rubber products, contributing to sustainability efforts. This shift not only reduces waste but also ensures that industries can meet the growing demand for eco-conscious materials.

Conclusion

In summary, flat rubber strips play a crucial role in numerous industries due to their unique properties and versatility. From automotive weatherstripping to construction sealing applications, these strips provide durable and reliable solutions. Their ability to adapt to various uses, coupled with cost-effectiveness and environmentally friendly options, positions flat rubber strips as indispensable components in today’s manufacturing landscape. Embracing this innovative material can lead to improved product performance and sustainability in countless applications.

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025