Telephone: +8618730949119

E-mail: 1299343081@qq.com

Feb . 06, 2025 06:37

Back to list

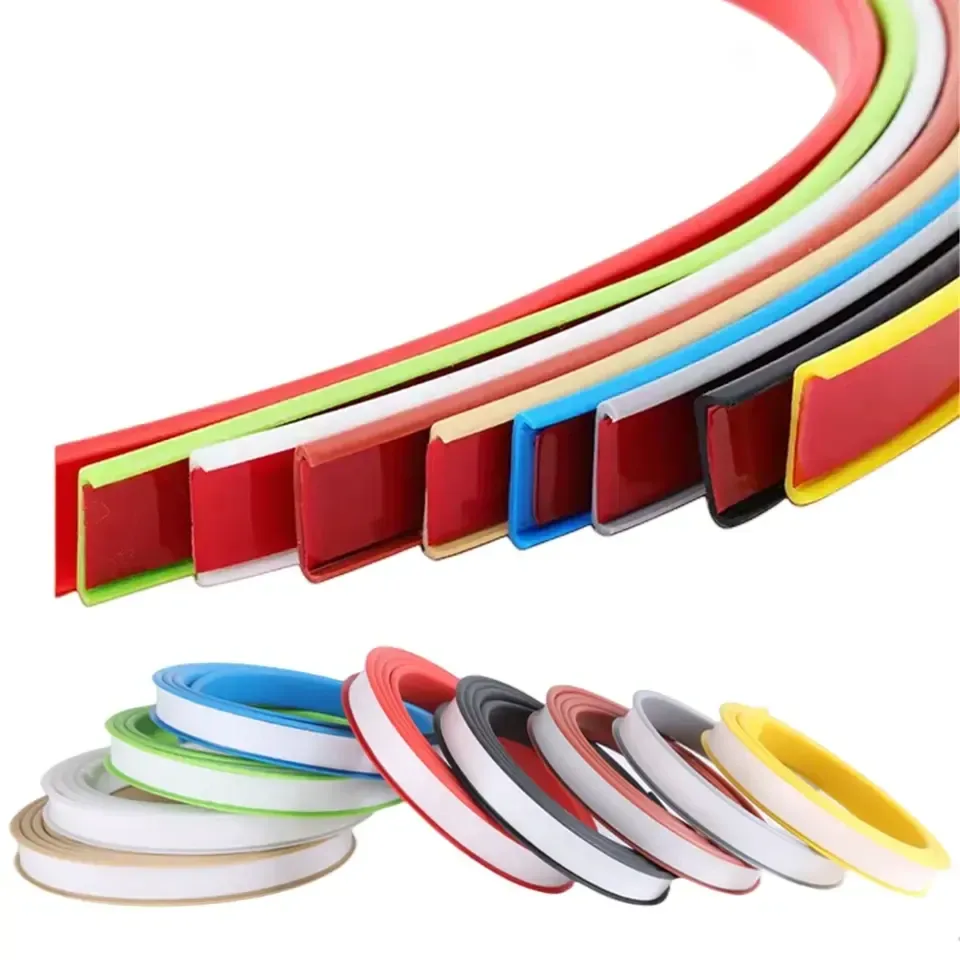

flat rubber strips

Flat rubber strips have become an indispensable component across a myriad of industries, owing to their versatility and functional prowess. From automotive to construction, these unassuming yet vital materials are engineered to serve a wide range of applications, each tailored to meet specific demands with precision. With the evolution of technology and materials science, flat rubber strips have witnessed significant advancements, rendering them more efficient and durable.

One cannot overlook the significance of choosing the right flat rubber strip for a specific application. Engaging with experts in material science and engineering can facilitate an informed decision, ensuring the selected rubber strip meets all application requirements in terms of performance, durability, and compliance with industry standards. Consulting with reputable manufacturers often yields customized solutions tailored to unique needs, which can prove invaluable in specialized applications. In terms of sustainability, the rubber industry is making strides towards eco-friendly practices. Recyclable and biodegradable materials are being developed and incorporated into the production process of rubber strips, minimizing environmental impact without compromising on quality or performance. As industries shift towards greener solutions, the demand for sustainable rubber products is on the rise, presenting opportunities for innovation and growth. The trustworthiness of a flat rubber strip manufacturer is paramount. A reputable provider not only guarantees the quality of their products but also offers robust support services, including installation guidelines and maintenance advice. Long-standing industry presence and positive testimonials from verified customers serve as indicators of authoritative and reliable manufacturers. In an era where product failures can lead to significant losses, relying on a trustworthy supplier is crucial. In conclusion, flat rubber strips are more than mere components; they are critical to the functionality and efficiency of numerous applications across various sectors. As technology advances, the role of these strips will continue to evolve, offering enhanced solutions to complex challenges. For businesses, making the informed choice in selecting the right material and partner is vital for ensuring optimum performance and longevity, paving the way for success in a competitive market landscape.

One cannot overlook the significance of choosing the right flat rubber strip for a specific application. Engaging with experts in material science and engineering can facilitate an informed decision, ensuring the selected rubber strip meets all application requirements in terms of performance, durability, and compliance with industry standards. Consulting with reputable manufacturers often yields customized solutions tailored to unique needs, which can prove invaluable in specialized applications. In terms of sustainability, the rubber industry is making strides towards eco-friendly practices. Recyclable and biodegradable materials are being developed and incorporated into the production process of rubber strips, minimizing environmental impact without compromising on quality or performance. As industries shift towards greener solutions, the demand for sustainable rubber products is on the rise, presenting opportunities for innovation and growth. The trustworthiness of a flat rubber strip manufacturer is paramount. A reputable provider not only guarantees the quality of their products but also offers robust support services, including installation guidelines and maintenance advice. Long-standing industry presence and positive testimonials from verified customers serve as indicators of authoritative and reliable manufacturers. In an era where product failures can lead to significant losses, relying on a trustworthy supplier is crucial. In conclusion, flat rubber strips are more than mere components; they are critical to the functionality and efficiency of numerous applications across various sectors. As technology advances, the role of these strips will continue to evolve, offering enhanced solutions to complex challenges. For businesses, making the informed choice in selecting the right material and partner is vital for ensuring optimum performance and longevity, paving the way for success in a competitive market landscape.

Next:

Latest news

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025