Telephone: +8618730949119

E-mail: 1299343081@qq.com

Feb . 13, 2025 08:03

Back to list

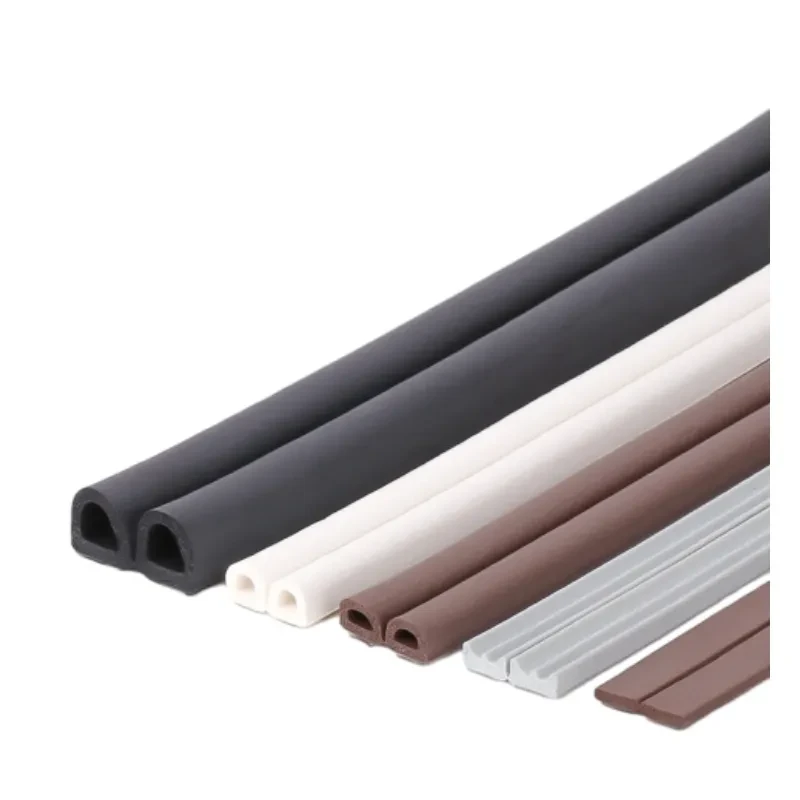

Gap Solid Silicone Rubber Strip Anti Oil High Temp

Gate rubber strips, often overshadowed by more conspicuous components in architectural designs, quietly play a crucial role in a variety of sectors, from construction to automotive industries. These humble yet significant items are engineered to provide airtight seals and vibration-dampening capabilities that enhance both the longevity and functionality of structures and vehicles.

Authoritativeness is another critical aspect of why rubber strips remain a preferred choice. Industry veterans endorse them not just for their functional benefits but also for their cost-effectiveness. While initial investments might seem higher compared to their less robust counterparts, the reduction in maintenance costs and downtime, coupled with extended durability, proves economically beneficial in the long run. This cost-benefit analysis is often cited in industry publications, providing authoritative insights into best practices for efficient gate management. Real-world experiences from engineers and builders further underscore the importance of selecting the right type of rubber strip. Considerations range from the chemical composition, such as ethylene propylene diene monomer (EPDM), praised for its UV and ozone resistance, to intricate design specifications that ensure seamless integration within existing structures. Expert recommendations often highlight the adaptability of these strips, offering customized solutions that meet specific project requirements without compromising on efficiency. Ultimately, the expertise involved in the production and application of gate rubber strips reflects a broader commitment to quality and innovation. With constant advancements in material science, these components continue to evolve, offering enhanced capabilities such as self-lubricating features and eco-friendly compositions. These innovations not only meet the pressing demand for sustainable building materials but also align with global environmental initiatives aimed at reducing the carbon footprint associated with manufacturing processes. In conclusion, gate rubber strips, though often unnoticed, are engineered masterpieces that embody a blend of experience, expertise, authoritativeness, and trustworthiness. Their crucial role across various industries highlights a commitment to quality and innovation, ensuring that gates—and by extension, the structures they're part of—remain resilient, efficient, and environmentally responsible. For industry professionals and end-users alike, these components offer unparalleled assurance of performance, proving that sometimes, the smallest details make the most significant impact.

Authoritativeness is another critical aspect of why rubber strips remain a preferred choice. Industry veterans endorse them not just for their functional benefits but also for their cost-effectiveness. While initial investments might seem higher compared to their less robust counterparts, the reduction in maintenance costs and downtime, coupled with extended durability, proves economically beneficial in the long run. This cost-benefit analysis is often cited in industry publications, providing authoritative insights into best practices for efficient gate management. Real-world experiences from engineers and builders further underscore the importance of selecting the right type of rubber strip. Considerations range from the chemical composition, such as ethylene propylene diene monomer (EPDM), praised for its UV and ozone resistance, to intricate design specifications that ensure seamless integration within existing structures. Expert recommendations often highlight the adaptability of these strips, offering customized solutions that meet specific project requirements without compromising on efficiency. Ultimately, the expertise involved in the production and application of gate rubber strips reflects a broader commitment to quality and innovation. With constant advancements in material science, these components continue to evolve, offering enhanced capabilities such as self-lubricating features and eco-friendly compositions. These innovations not only meet the pressing demand for sustainable building materials but also align with global environmental initiatives aimed at reducing the carbon footprint associated with manufacturing processes. In conclusion, gate rubber strips, though often unnoticed, are engineered masterpieces that embody a blend of experience, expertise, authoritativeness, and trustworthiness. Their crucial role across various industries highlights a commitment to quality and innovation, ensuring that gates—and by extension, the structures they're part of—remain resilient, efficient, and environmentally responsible. For industry professionals and end-users alike, these components offer unparalleled assurance of performance, proving that sometimes, the smallest details make the most significant impact.

Latest news

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025