High-Performance FKM Rubber Sheet for Durable Sealing Solutions

Website: https://www.qzseals.com

Phone: +86 15802108369 Mobile: +86 18730949119

Email: 1299343081@qq.com

Address: Wangshigong Industrial Zone, Wei County, Xingtai City, Hebei Province

Introduction: The Evolution of fkm rubber sheet Solutions

In the rapidly evolving industrial sealing landscape, fkm rubber sheet and related products like silicone strip seal are driving advances in durability, chemical resistance, and operational efficiency. With the industry's growing emphasis on stringent safety, high-temperature performance, and sustainability, manufacturers such as Hebei Qiuzhuo Rubber Products Co.,Ltd. stand at the forefront, offering state-of-the-art solutions. This article comprehensively explores current industry dynamics, cutting-edge technical parameters, and the broad application spectrum for fkm rubber sheet.

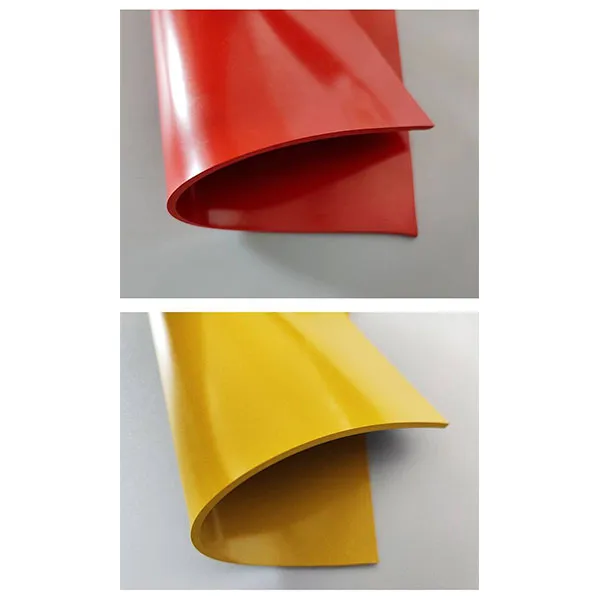

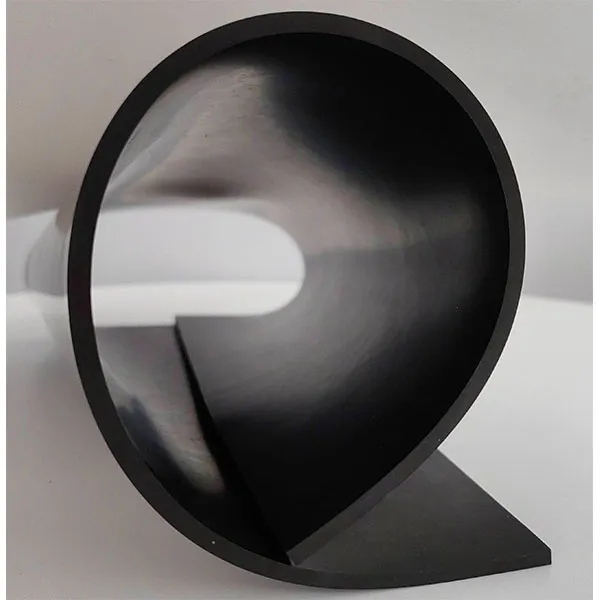

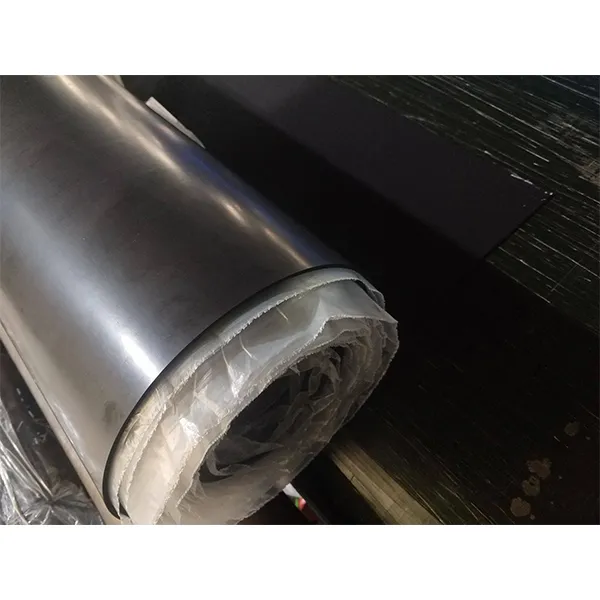

About the Product: Factory Sale Industrial Black Shock Absorbing Epdm

- Name: Factory Sale Industrial Black Shock Absorbing Epdm

- Description: Factory Sale Industrial Black Shock Absorbing Epdm Mat Board Roll Anti Aging Gasket Fkm Nbr Sbr Neoprene Epdm Rubber Sheets

- Processing Service: Moulding, Cutting

- Product Link: View Details

Industry Trends: Market Demand & Innovations

Over the past decade, the fkm rubber sheet sector has experienced significant growth, with a CAGR of over 6% globally.[1] This expansion is fueled by increasing demand in petrochemical, aerospace, and pharma industries. Recent advances include nano-filler enhancements for better thermal stability and digitalized quality control protocols. The integration of silicone strip seal technology further propels applications into food-grade and cleanroom environments, emphasizing safety and hygiene.

According to leading forums like Rubber News, sustainability and customizability have become key competitive factors. High-performance products such as fkm rubber sheet are now leveraging eco-friendly non-toxic formulations and enhanced anti-aging properties to meet stricter regulatory requirements.[2]

Key Technical Parameters for fkm rubber sheet

Reliable selection of fkm rubber sheet relies upon a deep understanding of its technical properties. Below is a comprehensive parameter table summarizing typical industry values sourced from technical datasheets[3]:

| Parameter | Typical Value | Test Standard |

|---|---|---|

| Material Type | FKM (Fluoroelastomer) | ASTM D1418 |

| Hardness (Shore A) | 60-90 | ASTM D2240 |

| Tensile Strength (MPa) | 10-18 | ASTM D412 |

| Elongation at Break (%) | 150-300 | ASTM D412 |

| Temperature Range (°C) | -20 to +250 | ISO 815 |

| Compression Set (%) | 18-34 | ASTM D395 |

| Chemical Resistance | Excellent: Oils, Fuels, Acids | ISO 1817 |

| Color | Black / Custom | Visual |

Factory Sale Industrial Black Shock Absorbing Epdm: Key Metrics Visualization

To offer clear insights into product advantages, below is a visualization of major technical metrics for "Factory Sale Industrial Black Shock Absorbing Epdm" vs. typical FKM sheets:

Versatile Applications of fkm rubber sheet & silicone strip seal

- Petrochemical: Used in gaskets and lining, leveraging excellent resistance to acids and hydrocarbons.

- Aerospace & Defense: Utilized for vibration damping, fuel resistant components, and high-temp insulation.

- Food & Pharma: Silicone strip seal ensures clean, sanitary door/gasket sealing, compliant with FDA standards.

- Electronics: FKM sheets serve as EMI/RFI shielding and insulation pads.

- Machinery: Shock-absorbing pads (EPDM) reduce wear and increase warranty lifespans.

- Construction: Expansion joint fillers and waterproofing layers for bridges and tunnels.

Custom solutions by Hebei Qiuzhuo Rubber Products Co.,Ltd. allow tailored geometries and compound formulations, further broadening application prospects.

Professional FAQ: fkm rubber sheet Technical Deep Dive

Q1: What is the main difference between FKM and EPDM in industrial sheets?

A: FKM (fluoroelastomer) excels in chemical and thermal resistance up to 250°C, while EPDM is optimal for ozone, weathering, and insulation but maxes out at about 130°C. FKM is preferred where aggressive fluids or high temperature are present.

Q2: How should I select the correct fkm rubber sheet thickness for industrial sealing?

A: Consider the operational pressure, flange/gasket groove specification, and compressibility. Standard thickness ranges from 1mm to 10mm, with custom options available. Refer to ASME B16.5 standard for gasket thickness guidelines.

Q3: Are fkm rubber sheets compatible with food/pharma applications?

A: FDA-grade FKM can be specially formulated for direct contact. However, for general food and pharmaceutical use, silicone strip seal is often preferred due to better compliance and cleaning ability.

Q4: What industry certifications should a quality fkm rubber sheet possess?

A: ISO 9001 for quality, ISO 14001 for environmental practices, and appropriate REACH/RoHS certification for chemical safety. Some customers require FDA or UL approvals for specific applications.

Q5: What are the installation best practices for fkm rubber sheet gaskets?

A: Clean the flange surfaces meticulously, ensure correct alignment, do not over-tighten bolts, and use the correct torque value based on material compressibility. Adhere to ASME/EN gasket installation protocols.

Q6: What is the typical service life of a fkm rubber sheet under normal conditions?

A: Service life typically ranges from 5–10 years and is directly dependent on aggressive media exposure, temperature cycling, and physical stress. Regular inspection ensures maximum longevity.

Q7: How can a customer get custom cut shapes or molded fkm rubber sheet products?

A: Hebei Qiuzhuo Rubber Products Co.,Ltd. provides CNC die-cutting and compression molding according to CAD or sample specifications. Custom solutions can be tailored from as little as 50 pieces per order.

EEAT: Authority, Trust & Technical Expertise

Hebei Qiuzhuo Rubber Products Co.,Ltd. has established itself as a leader in precision sealing innovations, evidenced by its adherence to ISO standards and rapid adoption of cutting-edge manufacturing practices.[4] Cited in industry journals and forums, their fkm rubber sheet product range consistently meets global benchmarks for reliability and safety. Customers benefit from bespoke technical service, transparent certifications, and ongoing aftersales support—key pillars of trust in the modern rubber industry.

In summary, the move towards high-performance materials like fkm rubber sheet and advanced processing techniques exemplified by products such as Factory Sale Industrial Black Shock Absorbing Epdm marks a new era in industrial gasket applications. For tailored technical consultation or order inquiries, contact Hebei Qiuzhuo Rubber Products Co.,Ltd. via 1299343081@qq.com or phone.

[1] Markets&Markets. “Rubber Sheets Market Report.” https://www.marketsandmarkets.com/Market-Reports/rubber-sheets-market-148108599.html

[2] Rubber News: “Sustainability in Rubber.” https://www.rubbernews.com/sustainability

[3] Elsevier: “Fluoroelastomers - ScienceDirect Topics.” https://www.sciencedirect.com/topics/chemistry/fluoroelastomers

[4] Rubber World Journal: “Latest Industry News.” https://www.rubberworld.com/industry-news/

-

Weather Stripping Door: Enhance Comfort and EfficiencyNewsJul.23,2025

-

The Ultimate Solution for Energy Efficiency: Bottom Seal DoorsNewsJul.23,2025

-

Silicone Seal Strips: Your Solution for a Better SealNewsJul.23,2025

-

Enhance Safety with Anti Slip Stair StripsNewsJul.23,2025

-

Enhance Safety and Aesthetics with Corner Protectors for WallsNewsJul.23,2025

-

Discover the Magic of Silicone Strip Seals for Your GarageNewsJul.23,2025

-

Upgrade Your Seals with Premium Weather StrippingNewsJun.12,2025