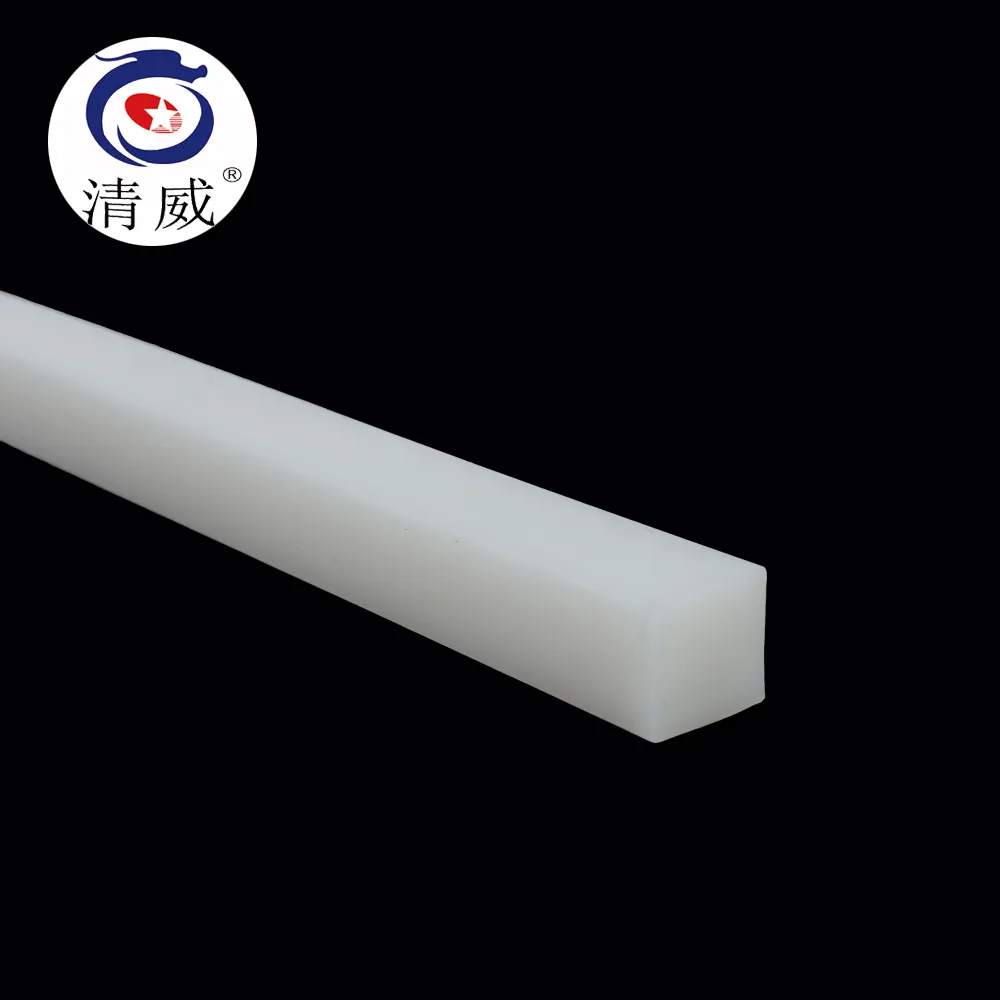

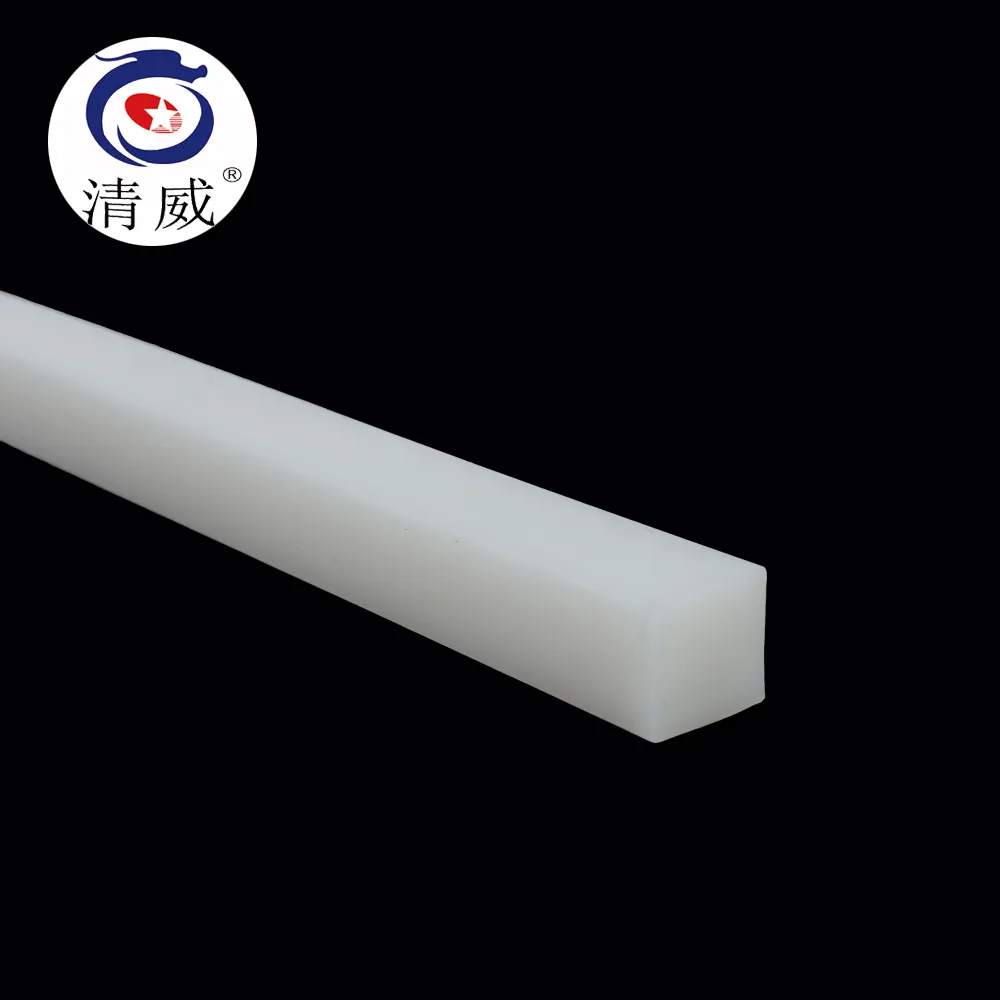

High-Quality Silicone Strip Seal for Doors & Windows Weatherproof

In the rapidly evolving field of industrial sealing, the silicone strip seal and its family of derivatives—such as silicone weather stripping, wood door weather stripping, silicone door seal strip, and door bottom seal rubber strip—are essential for efficiency, protection, and cost-effectiveness. With increasing performance requirements in petrochemical, metallurgy, and water treatment sectors, choosing the right sealing solution is crucial for modern engineering and facility management.

1. Overview of the Silicone Strip Seal Industry (2024 Trend Analysis)

The last decade has witnessed silicone strip seal market surge, fueled by urbanization, green building codes, and stricter industrial standards. According to MarketsandMarkets, the global silicone elastomer market is projected to reach USD 9.6 billion by 2026, growing at a CAGR of 6%.

- Growth Sectors: Energy, HVAC, aerospace, marine, automotive, and pharmaceutical industries.

- Key Trends: Enhanced fire resistance, eco-friendly compounds, precision machining, and advanced ISO/FDA certifications.

2. Core Technical Parameters of Silicone Strip Seals (With Data Table)

silicone strip seal solutions are defined by several key technical parameters, influencing their suitability for a range of applications.

| Parameter | Typical Value | Standard/Remark |

|---|---|---|

| Material | Solid Silicone Rubber | FDA/ISO 9001 Compliant, Non-toxic |

| Hardness | 40-80 Shore A | ASTM D2240 |

| Temperature Resistance | -60°C to +250°C | UL94 V-0 Fire Rated |

| Compression Set | < 25% | ISO 815 |

| Tensile Strength | > 7 MPa | ISO 37 |

| Elongation at Break | 300-550% | ISO 37 |

| Chemical Resistance | Excellent (Oil, Ozone, UV, Acid, Alkali) | DIN 53521 |

| Color | Customer Specified | Customizable |

3. Manufacturing Process — Flowchart with Key Stages

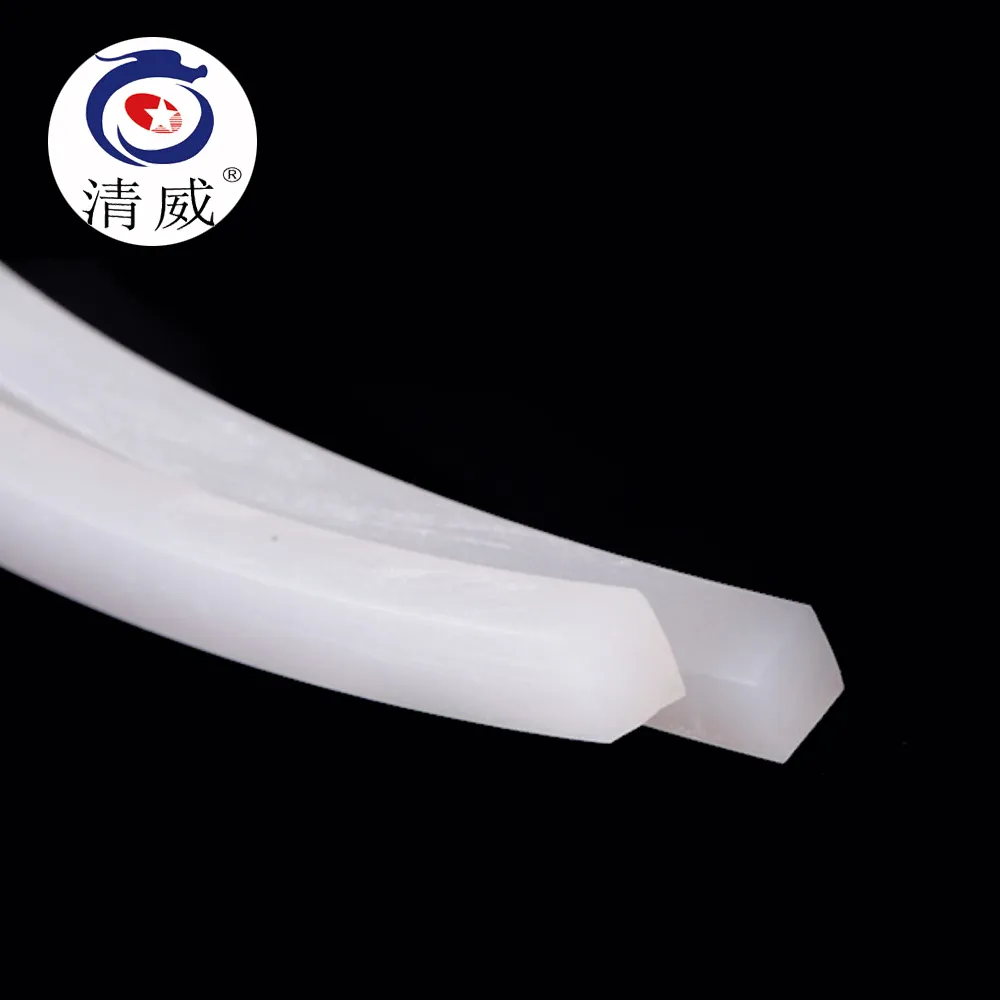

The production of high-quality silicone strip seal involves rigorous steps to ensure compliance with international standards (such as ISO 3302-1, FDA 21 CFR 177.2600). Below is a clear flowchart of the manufacturing process, highlighting the distinctive features of the Gap Solid Silicone Rubber Strip Anti Oil High Temp product.

- Raw Material Inspection: Only 100% silicone polymers from certified suppliers are accepted. Each batch tested for purity and consistency.

- Mixing: Reinforcing fillers, colorants, & high-temp stabilizers are blended in controlled batches.

- Extrusion Molding: Advanced dies ensure precise dimensions and surface quality to ISO 3302-1 standards.

- Curing / Vulcanization: Cross-linking improves elasticity and thermal stability (180–220°C, specific time per batch).

- CNC Cutting: Customized profiles and exact lengths tailored to client specs.

- Quality Inspection: 100% surface & dimensional checks per order, mechanical property tests (ISO 37, ISO 815, UL94, etc.)

- Packing & Shipping: Custom packaging protects seals during global transport.

4. Product Specifications — Gap Solid Silicone Rubber Strip Anti Oil High Temp vs Alternatives (Comparison Table & Chart)

This section provides a direct data-driven comparison of silicone strip seal products.

| Product | Hardness (Shore A) | Temp. Range (°C) |

Oil Resistance | Compression Set | Lifetime | Certification |

|---|---|---|---|---|---|---|

| Gap Solid Silicone Rubber Strip Anti Oil High Temp | 50–60 | -60 to +250 | Excellent | <20% | 10+ years | ISO, FDA |

| Standard EPDM Strip | 60–70 | -40 to +120 | Good | <30% | 4–6 years | ISO |

| PVC Weatherstrip | 65–80 | -20 to +55 | Poor | >40% | 2–4 years | RoHS |

5. Typical Application Scenarios and Technical Advantages

- Petrochemical Facilities: Reliable high-temp seals for pipe flanges, manways, and vessels. Prevents oil/chemical leaks, UV and ozone resistant for outdoor exposure.

- Metallurgical Plants: Sealing for furnace doors, conveyor lines, and expansion joints. Prevents heat loss and enhances workplace safety, non-toxic and flame-retardant.

- Water & Wastewater Treatment: Ensures tight sealing in clarifier tanks, control panels, and pipe couplings. Inert to chlorine and acids—extends maintenance intervals.

- HVAC & Cleanrooms: Effective silicone weather stripping for doors (e.g., wood door weather stripping), windows, and ventilation hatches, achieving energy savings up to 17% (ASHRAE Study).

- Food-Grade & Medical: FDA-compliant silicone door seal strip for cleanrooms, laboratories, and processing lines, supporting stringent hygiene protocols.

Adopting silicone strip seal products significantly reduces energy costs, increases system longevity, and minimizes unplanned maintenance outages.

6. Manufacturer Comparison & Customization Solutions

When selecting a silicone strip seal supplier, key differentiators include:

- Material Purity & Source Guarantees (Third-party testing, such as SGS/FDA/ISO 9001)

- Manufacturing Techniques (precision extrusion, CNC, automated defect-detection, quality control with CMM—Coordinate Measuring Machines)

- Lead Time (standard: 7–10 days; customization: 15–28 days)

- Customization (material color, hardness, cross-sectional profile, flame rating, adhesive backing, logo printing, etc.)

- After-sales & Technical Support (24/7 hotline, documentation, failure analysis, field guidance)

- Global Track Record (clients in 30+ countries, testimonials in oil & gas, aerospace, food, and pharma industries).

7. Real-World Application Examples & Customer Feedback

- Oil Refinery Gasket Sealing: "Even after 5 years and over 300°C spike exposures, the silicone strip seal from QZ Seals far outperforms imported alternatives. No visible hardening or cracks!" — Chief Maintenance Engineer, Nanjing Petrochemical

- Food Processing Door Seals: "FDA test-passed, safe for daily cleaning, easy installation. Eliminated all cold-room condensation issues. Strongly recommended for the food sector." — Head of Engineering, Shanghai Freshways Foods

- Pharmaceutical Cleanroom Expansion Joints: "No blackening or aging after 16 months' intensive sterilization. Good fit and tight tolerance—received with full ISO reports." — Project Supervisor, Germany Pharmatech AG

8. FAQ: Expert Answers on Silicone Strip Seal Technology

- Q1: What is the main raw material of a silicone strip seal, and what are its unique properties?

- A: The core material is solid silicone rubber, renowned for extreme thermal resistance (-60°C to +250°C), high elasticity, FDA non-toxicity and superb resistance to oil, ozone, UV, and chemicals.

- Q2: What does “Shore A hardness” indicate for a silicone door seal strip?

- A: “Shore A” quantifies material hardness, ranging 40–80 for most silicone seals. Lower values offer more flexibility and compression; higher values increase wear-resistance.

- Q3: What international quality standards are typically required?

- A: Top-grade products meet ISO 3302-1 (dimensional tolerances), FDA 21 CFR 177.2600 (food safety), and, if fire safety is needed, UL94 (V-0) flame rating.

- Q4: How do I select proper dimensions for door bottom seal rubber strip installation?

- A: Measure the gap width, door movement, and anticipated compression. Strips should compress by 20–30% for optimal long-term sealing without excessive friction or wear.

- Q5: What are the recommended installation standards?

- A: Use clean, flat mounting surfaces. For adhesive backing, degrease thoroughly. For mechanical fixing, follow OEM-recommended fastener spacing (generally

- Q6: How long is the typical service life, and what factors may reduce it?

- A: Properly installed silicone strip seals last 8-14 years depending on temperature, UV, chemicals and movement frequency. Excessive compression set or direct flame may shorten service life.

- Q7: Are there safety or environment certificates for reputable manufacturers?

- A: Yes, look for ISO 9001:2015, ISO 14001, and FDA/LFGB (for food-grade), plus MSDS documentation and RoHS for global export compliance.

9. Delivery, Warranty & Customer Support

- Standard Lead Time: 7–10 working days for standard bulk orders; customized sealing profiles: 15–28 days from drawing approval.

- Warranty: All silicone strip seal products backed by 2–5 year material & manufacturing defect warranty. Detailed warranty certificates available on request.

- Support: 24/7 technical hotline support, on-site installation guidance (for bulk clients), rapid global shipping by DHL/UPS/FedEx/sea.

- Aftermarket Service: Root cause analysis, failure investigation, batch traceability, and continuous improvement feedback.

For urgent inquiries, engineering support or international tenders, contact QZ Seals technical team directly.

10. References & Further Reading

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025

-

Top Safety Standards for Corner ProtectorsNewsJul.29,2025

-

Step-By-Step Guide to Replacing Garage Door SealsNewsJul.29,2025

-

How to Fix a Loose Under Door Draught StopperNewsJul.29,2025

-

Edge Banding Tape for High-Traffic Commercial SpacesNewsJul.29,2025

-

Best Heat-Resistant Materials for Cooker Door SealsNewsJul.29,2025

-

Weather Stripping Door: Enhance Comfort and EfficiencyNewsJul.23,2025