Effective Sealing Solutions for Marine Weather Protection and Energy Efficiency

Understanding Marine Weather Stripping A Guide for Boat Owners

Marine weather stripping is an essential component for any boat owner looking to maintain their vessel's integrity against the elements. This specialized seal not only enhances the comfort of those aboard but also protects the boat's structure from water intrusion and damage. In this article, we will delve into the importance, types, installation, and maintenance of marine weather stripping.

The Importance of Marine Weather Stripping

Marine environments are harsh and unyielding. Boats are constantly exposed to saltwater, rain, wind, and sun, all of which can compromise their structural integrity over time. Weather stripping acts as a barrier that prevents water from entering the boat, which can lead to mold growth, rot, and deterioration of essential components.

Additionally, effective weather stripping contributes significantly to energy efficiency. By sealing gaps, it minimizes the need for heating and cooling systems to work overtime, thus reducing fuel consumption and operating costs. For recreational boaters, this translates into more enjoyable outings with minimal disruptions.

Types of Marine Weather Stripping

There are various types of marine weather stripping available, each designed for specific applications

1. Rubber Seals Commonly used around hatches, doors, and windows, rubber seals provide excellent elasticity and durability. They can withstand the rigors of marine environments while maintaining a tight seal.

2. Foam Tape This lightweight, flexible option is typically used in less critical areas. Foam tape is easy to apply and can fill irregular gaps effectively.

3. Vinyl and Neoprene Strips Ideal for use with sliding doors and panels, these strips offer good resistance to corrosion and weathering. Their flexibility makes them suitable for moving parts.

4. Molded Gaskets Specifically designed to fit intricate shapes, molded gaskets provide a tight seal around various components, including machinery and engines.

Installation of Marine Weather Stripping

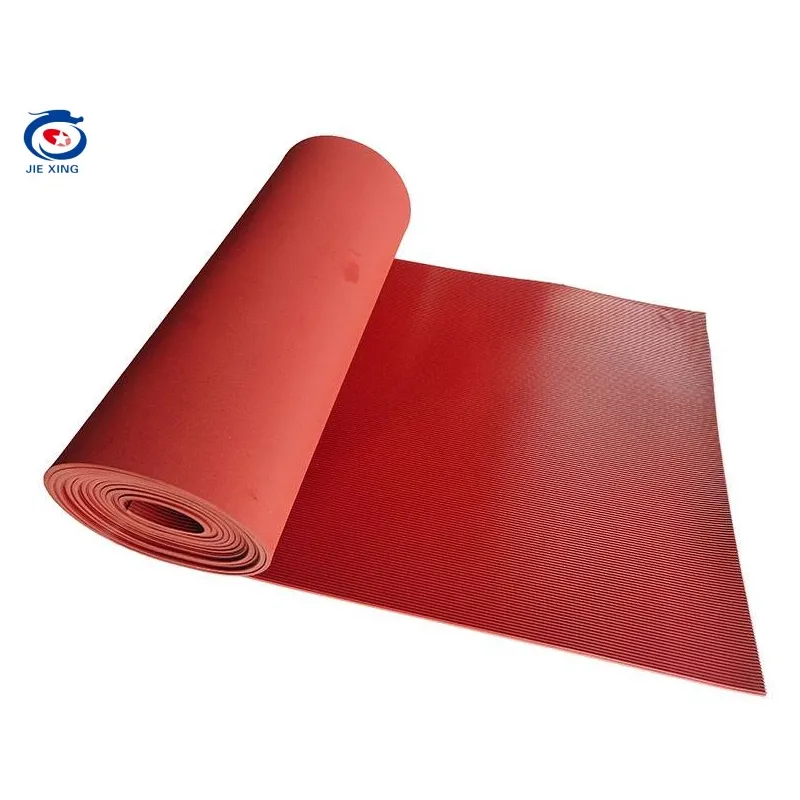

marine weather stripping

Proper installation of weather stripping is crucial for maximizing its effectiveness. Here are some steps to guide you through the process

1. Assess the Areas Needing Sealing Identify gaps or areas where water may enter the boat. Common locations include hatches, doors, windows, and storage compartments.

3. Clean the Surface Ensure that the surfaces where the weather stripping will be applied are clean and free of dirt, grease, and old adhesive. A clean surface promotes better adhesion.

4. Cut to Size Measure and cut the weather stripping to the required lengths. Accuracy is important to achieve a snug fit.

5. Apply Adhesive (if needed) Some weather stripping options come with adhesive backing, while others may require an additional adhesive. Follow the manufacturer's instructions for the best results.

6. Press Firmly Once in place, press the weather stripping firmly against the surface to ensure a tight seal.

Maintenance of Marine Weather Stripping

To ensure the longevity of your marine weather stripping, regular maintenance is essential. Inspect the seals periodically for signs of wear or damage, especially after harsh weather conditions. Clean the weather stripping with mild soap and water to remove salt and debris that may cause degradation.

Replace any sections that show cracks or other signs of aging to maintain optimal performance. Keeping the edges of windows, doors, and hatches well-groomed and free from build-up can also prolong the life of the weather stripping.

In conclusion, marine weather stripping is a vital part of boat maintenance that ensures comfort, safety, and longevity. By understanding the different types available, implementing proper installation techniques, and committing to routine maintenance, boat owners can protect their investment and enjoy countless adventures on the water.

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025