Plywood Edge Trimming Solutions for a Smooth Finish and Enhanced Durability

Understanding Plywood Edging Strips Enhancing Aesthetics and Durability

Plywood is a versatile construction material known for its strength, stability, and various applications, ranging from furniture making to structural components in buildings. One of the essential aspects of working with plywood is the finishing touches, and this is where plywood edging strips come into play. These strips not only enhance the visual appeal of plywood surfaces but also contribute to the durability and longevity of the material.

What are Plywood Edging Strips?

Plywood edging strips, often referred to as edge banding, are thin strips of wood or a composite material that are applied to the raw edges of plywood panels. These strips serve several purposes they conceal the exposed plywood edges, provide a finished look, and protect the edges from moisture, wear, and tear. Edging strips can be made from a variety of materials including solid wood, veneer, and melamine, allowing for a wide range of aesthetic choices.

Importance of Edging Strips

1. Aesthetic Appeal One of the primary reasons for applying edging strips is to enhance the visual appearance of plywood projects. Raw edges can look unfinished and unattractive, but with the right edging, they can look polished and professional. Various finishes and color options are available, allowing for customization to match the overall design of the piece.

2. Protection Edges of plywood are more susceptible to damage, including chipping, splintering, and moisture penetration. Applying edging strips provides a protective barrier against these threats. This is especially crucial in environments where the plywood may be exposed to high humidity or accidental impacts.

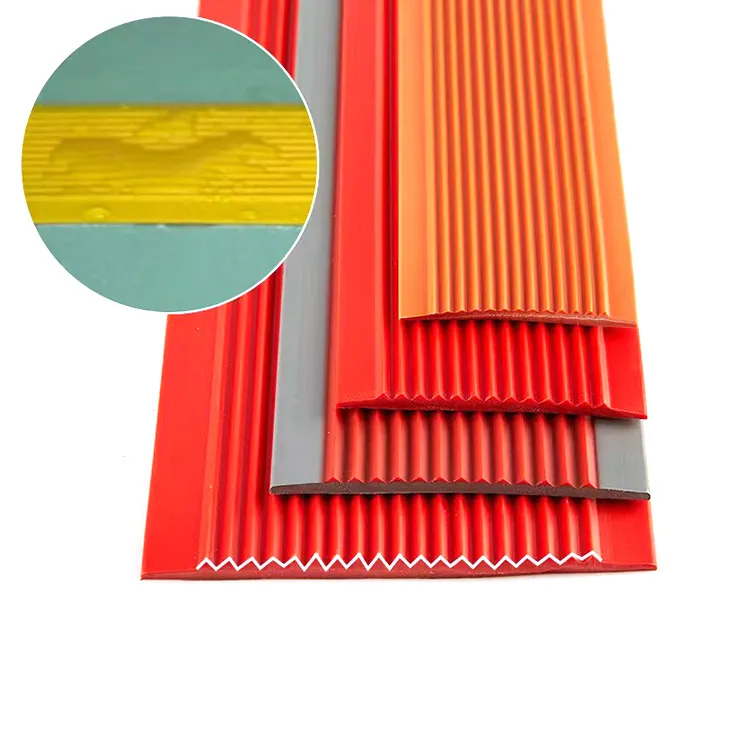

plywood edging strip

3. Durability Using edging strips can significantly increase the lifespan of plywood products. The banding acts as a shield, preventing water and contaminants from seeping into the plywood layers, which can lead to warping, delamination, or rotting over time. This durability is essential in both furniture applications and construction elements that require long-lasting materials.

4. Ease of Maintenance Finished edges are easier to clean and maintain compared to raw plywood edges. Edging strips can be designed to be resistant to staining and dirt accumulation, making them a practical choice for high-traffic areas or surfaces that are prone to spills.

Types of Edging Strips

There are several types of edging strips available, each suited for different applications

- Wood Veneer Edging Offers a natural wood look and can be stained or finished to match the project. This type is ideal for furniture and cabinetry where appearance is a priority. - PVC Edging A more affordable option that comes in various colors and wood grain patterns. PVC is also moisture-resistant, making it suitable for kitchen and bathroom applications. - Melamine Edging Often used in laminate products, melamine edging is durable and easy to clean. It is available in various colors, providing versatility in design.

Conclusion

In summary, plywood edging strips are an essential component of any plywood project, promoting not only aesthetics but also longevity and protection. With a wide range of materials and styles available, these strips allow craftsmen and DIY enthusiasts alike to elevate their work to a professional standard. Whether you are building furniture, cabinetry, or engaging in larger construction projects, investing in quality edging strips can make a significant difference in the final product's quality and durability.

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025