Premium Edge Banded Solutions for Plywood & Furniture

In the realm of modern furniture and interior construction, edge banded solutions have become a crucial aspect of material aesthetics, durability, and cost-effectiveness. Whether it’s plywood, MDF, or particleboard, high-performance edge banding tape and edge tape for plywood protect material edges and provide a premium finish, significantly boosting overall value. This comprehensive guide offers deep insights into technologies, parameters, manufacturing processes, application scenarios, and leading solutions such as the Edge Banding Tape Furniture Wood Board Cabinet Tab, empowering you to make data-driven decisions for your next project.

1. Market Trends & Global Demand for Edge Banded Products

According to recent industry reports, the global edge banded market was valued at $1.8 billion in 2023, projected to reach $2.5 billion by 2028 at a CAGR of ~6.7% (source). The adoption is powered by demands for moisture-resistant, visually uniform, and low-VOC furniture in residential, retail, and contract interiors.

The trend chart above demonstrates the consistent growth in edge banded demand globally. Drivers include eco-friendly materials, quick installation systems, and technological improvements in veneer strip and pvc edge banding tape.

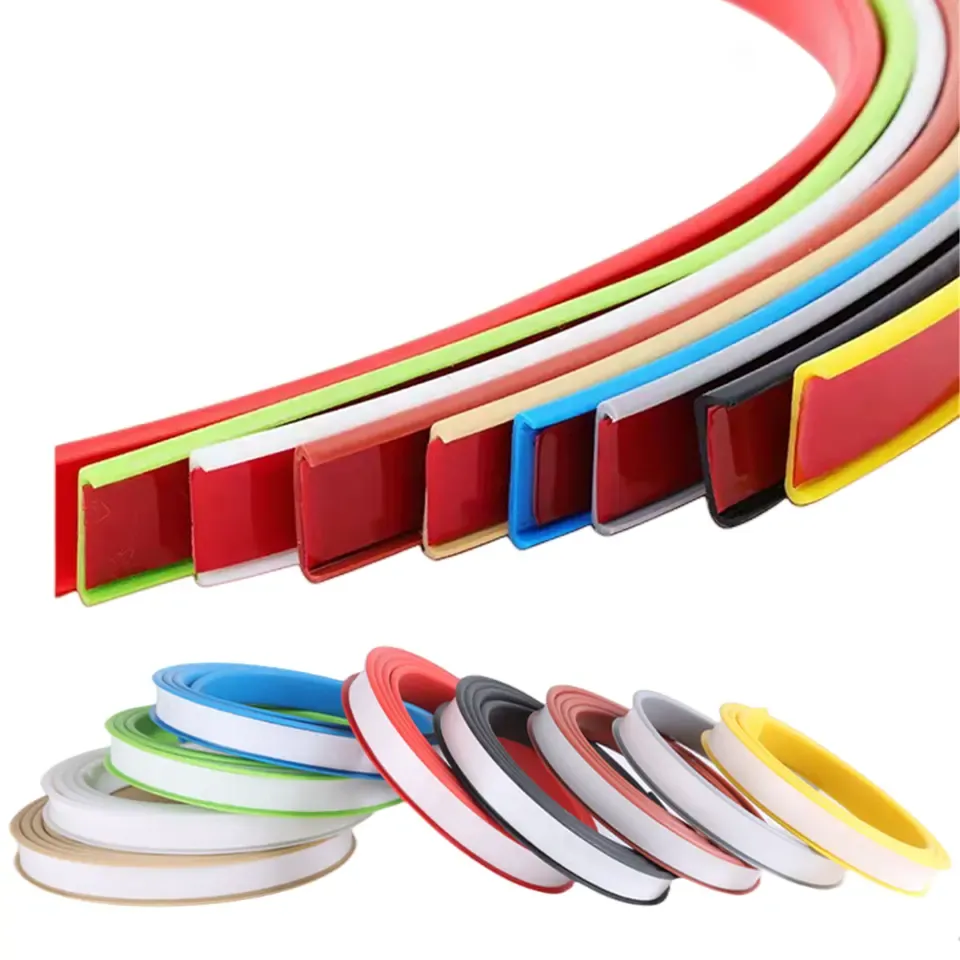

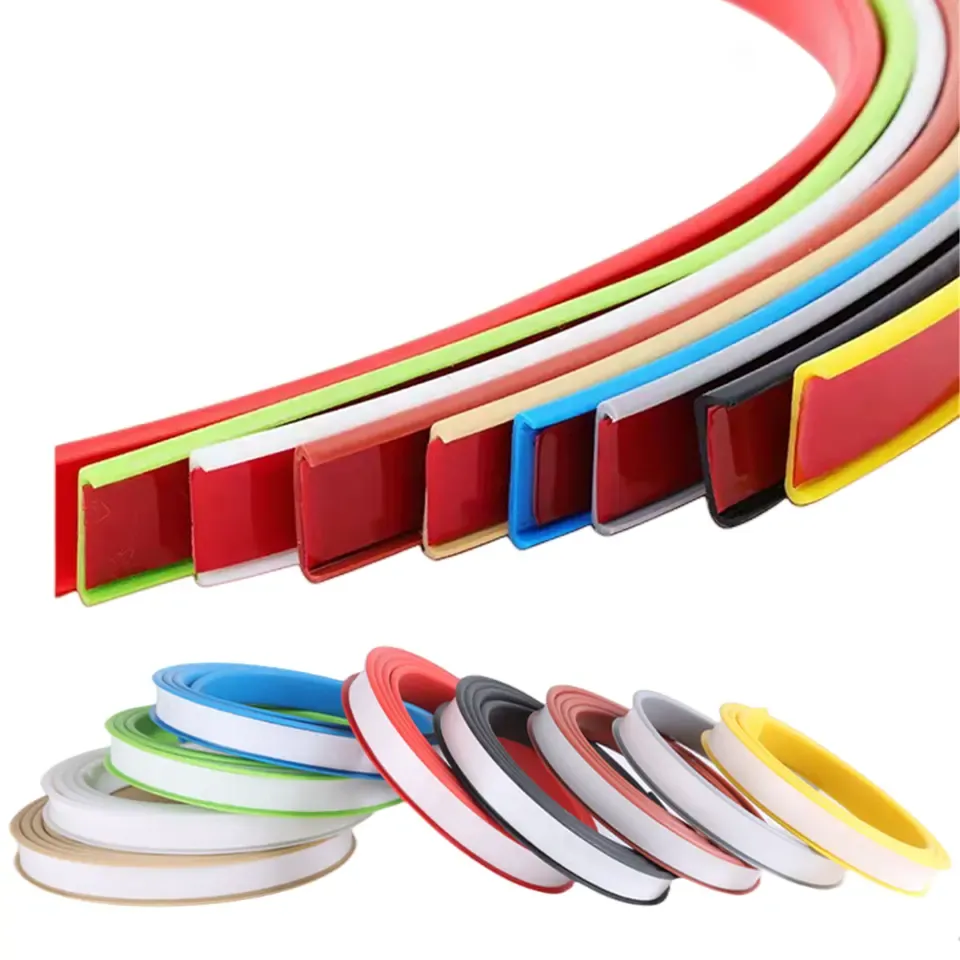

2. Edge Banding Tape Furniture Wood Board Cabinet Tab – Product Overview

- Product Name: Edge Banding Tape Furniture Wood Board Cabinet Tab

- Website: Official Product Page

- Core Keywords: edge banded, edge banding tape, edge tape for plywood, veneer strip, pvc edge banding tape

- Standard Compliance: ISO 9001:2015, SGS, RoHS, ANSI/BIFMA

- Applications: Residential and commercial furniture, modular cabinetry, plywood, MDF/particleboard, laboratory fixtures, office workstations

| Parameter | Specifications | Industry Reference |

|---|---|---|

| Width | 16mm – 63mm | Common cabinet standard |

| Thickness | 0.4mm – 2.0mm (PVC), 0.6mm – 3.0mm (ABS/Wood Veneer) | ISO 2424, ANSI/BIFMA |

| Length/Roll | 50m, 100m, Customizable | Production flexibility |

| Material | PVC, ABS, PMMA, Real Wood Veneer, Melamine | RoHS, Formaldehyde-free |

| Finish | Glossy, Matte, Textured, Woodgrain | Decor compatability |

| Color | Solid/wood colors, custom matched | OEM/ODM support |

| Adhesive type | EVA, PUR, Hot-melt | ISO 4892 aging tests |

| Service Life | 15+ years (PVC), 5-10 years (Veneer) | Accelerated test results |

Edge Banded Manufacturing Flowchart

Key Steps Explained

3. Technical Parameter Comparison: Edge Banding Types

Recommendation:

- For heavy-duty or humid environments (kitchens/bathrooms, lab cabinetry): PVC or PMMA edge banded solutions are best.

- For premium aesthetics or solid wood feel: Use wood veneer strip.

- For affordable and easy application: Melamine or ABS-based edge tape for plywood is suitable.

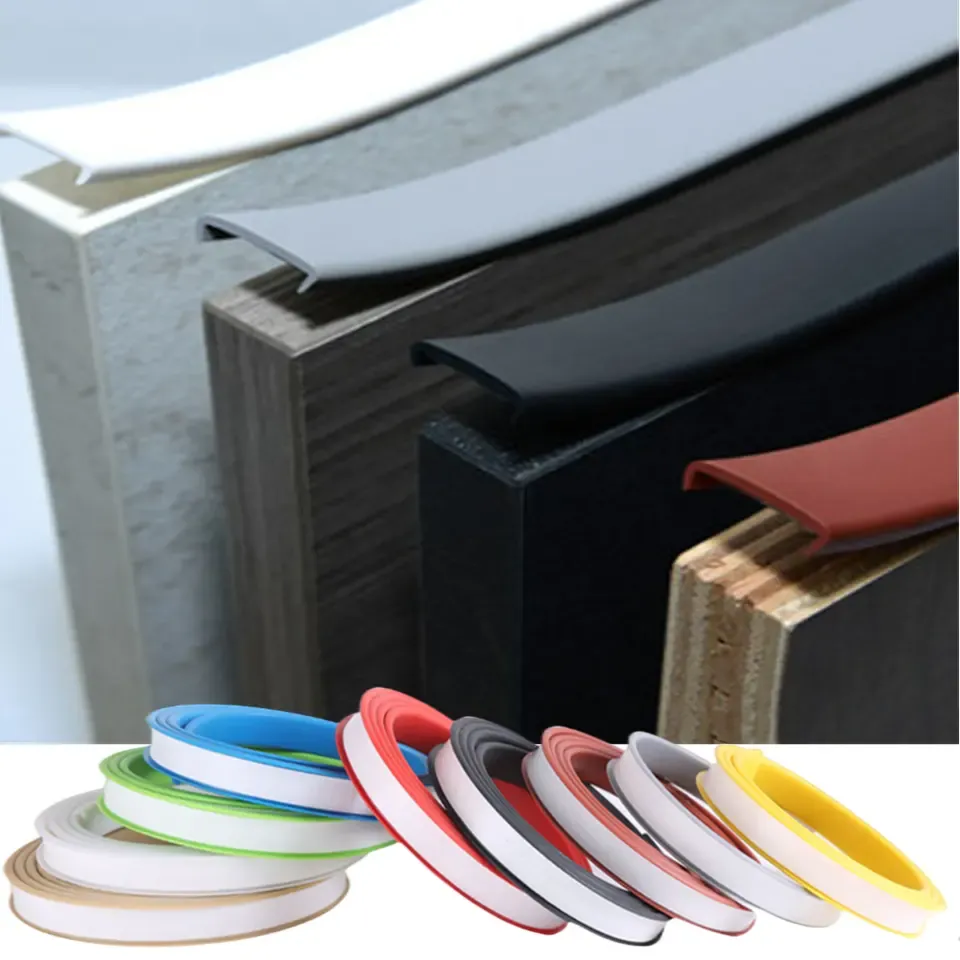

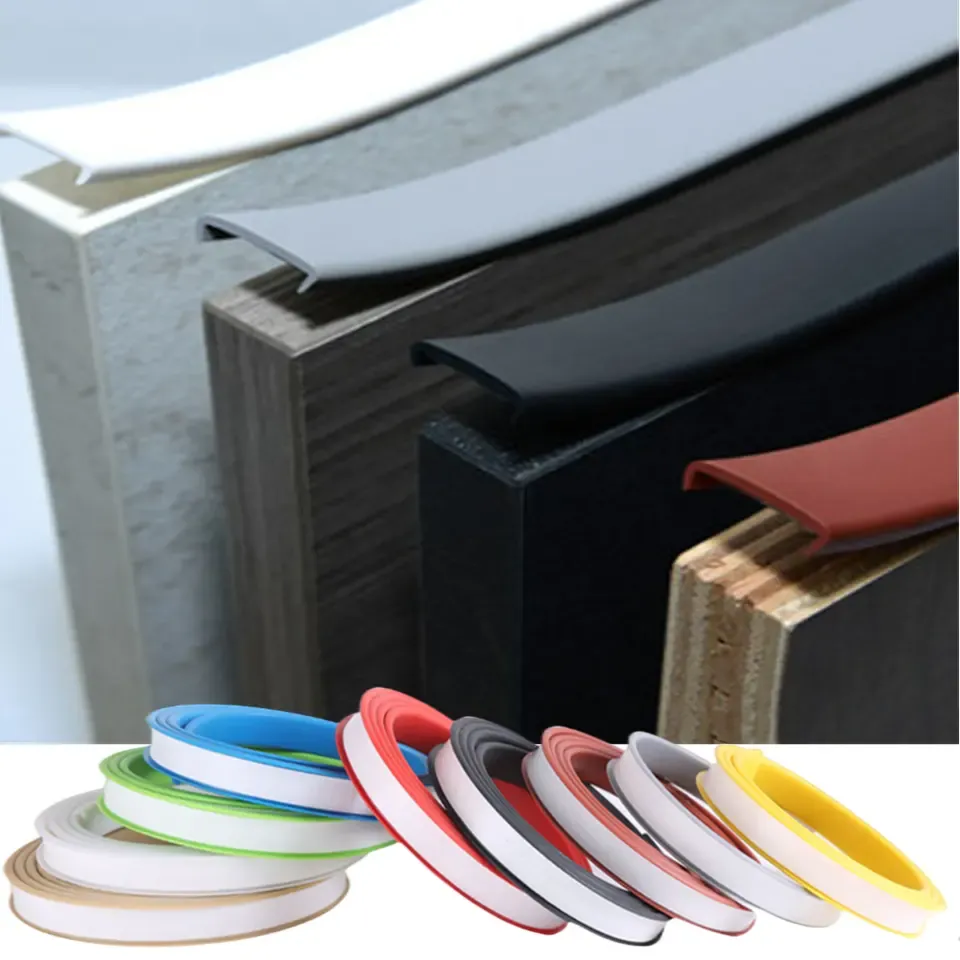

4. Application & Technical Advantages of Edge Banded Solutions

- Protection: Shields raw board edges from chips, moisture, and chemicals.

- Energy Efficiency: Edge sealing prevents warping and reduces the penetration of external agents, contributing to longer lifespan (PROVEN: Boards with edge banded tape show 65% less edge pop-out post water-boil test; see ScienceDirect).

- Customization: Support for OEM/ODM, color, and grain matching to any furniture design, including fire-resistance and antibacterial options.

- Standards Assurance: All mainstream edge banded products conform to ISO 9001, ANSI/BIFMA, SGS and RoHS/FSC requirements.

- Industry Use Cases:

- Residential interiors: Kitchens, wardrobes, TV cabinets, bedroom sets

- Commercial projects: Office workstations, hotel furniture, laboratory benches

- Industrial/Healthcare: Cleanroom benches, modular hospital furniture

- Scenario: 600LM of customized retail shelving, subject to daily cleaning and high contact frequency.

- Solution: 2mm thick pvc edge banding tape (color-matched oak grain), with hot-melt adhesive for quick installation.

- Outcome: After two years, edge banded units exhibited no visible delamination, chips, or loss of appearance as confirmed by end-user reviews and cross-section inspection.

- Standard Referenced: ISO 4892 accelerated aging, ANSI BIFMA X5.5 collision tests.

5. Industry Manufacturer Comparison Table

| Supplier | Main Material | Width Range (mm) | Min. Thickness | Certification | MOQ | Global Clients |

|---|---|---|---|---|---|---|

| Edge Banding Tape Furniture Wood Board Cabinet Tab | PVC, ABS, Wood Veneer, PMMA | 16–63 | 0.4mm (PVC) | ISO 9001, SGS, ANSI | 100 rolls | IKEA, Ashley Furniture, Midea, Vanke |

| Rehau | PVC, ABS, PP | 19–60 | 0.5mm | ISO 9001, FSC | 500 rolls | Herman Miller |

| Doellken | PVC, ABS, Acrylic | 18–55 | 0.45mm | ISO 9001, BIFMA | 200 rolls | Steelcase, Haworth |

| Tece | PVC, ABS, Melamine | 18–54 | 0.4mm | SGS, TÜV | 200 rolls | Local OEMs |

6. Custom Edge Banded Solutions & Service Commitments

- Custom Color/Texture Matching: 99.5% color accuracy using advanced color spectrophotometers.

- Special Profiles & Serial Edges: Multi-radius, multi-groove and post-formed edge banded profiles for premium furniture brands.

- Adhesive Solutions: EVA, PUR, and laser-activated tapes for seamless “zero-joint” installations.

- Lead Time: Standard products 5–7 business days; custom solutions 12-20 days (project-dependent).

- Warranty: 5-Year Performance Guarantee on color, adhesion, and finish integrity; replacements or refunds for product deviation, with global technical support.

- Onsite Technical Support: Installation consultancy, equipment calibration, and post-sales aftercare.

PVC edge banded tape dominates the market, favored in both residential and commercial applications.

7. Real-World Application Gallery

8. Customer Experience & Reviews

Furniture Manufacturer (Europe): “Switching to edge banded tape from QZSeals reduced our rejects ratio by 63% and customer complaints on edge chips to near zero. RAL color matching is perfect.”

Global OEM Buyer: “Tested under ANSI BIFMA X5.5, the tape held up to over 12,000 rub cycles – adhesion and flexibility are top-notch.”

Construction Contractor: “Rapid custom production capacity and technical support make complex fit-outs feasible within tight deadlines.”

9. Professional FAQ – Edge Banded, Tape & Industry Standards

A1: Edge banded refers to the finished state of a board with its edges protected and decorated, usually by tapes (PVC, ABS, melamine, or wood veneer strips), while PVC edge banding tape is the most common synthetic tape, and veneer strip denotes thin layers of real wood for premium or solid wood aesthetics.

A2: Market standards range from widths of 16mm–63mm and thicknesses between 0.4mm–2.0mm, but custom sizes are available per project needs.

A3: PVC and ABS edge banding tapes from certified brands meet RoHS, REACH, and low-VOC/low-formaldehyde standards. FDA-grade versions are also available for food processing furniture.

A4: Use CNC-controlled edge banding machines with precise temperature (160°C–220°C for hot-melt), consistent feed rates, and compression rollers for bubble-free, seamless finish. Reference: ISO 9001, ANSI/BIFMA standards.

A5: All exports are batch-checked for color, adhesion, impact resistance, and environmental safety, with certificates provided (ISO 9001:2015, SGS, RoHS, BIFMA, and project-specific reports).

A6: In-house spectrometer and digital print matching ensure precise replication of any sample or design, digitally archived for repeat orders.

A7: Standard edge banded tape is usually delivered in 5–7 days. Custom orders may take 12–20 days. Dedicated technical support is available worldwide.

10. Key Takeaways: Why Upgrade Your Project to Edge Banded Solutions?

- Durability & Value: Boards with quality edge banded protection offer superior edge strength, stain resistance, and extended service life in demanding installations.

- Sustainability: Lower VOC, recyclable options, and eco-certification support green building initiatives.

- Customization & Trend Leadership: Wide range of finishes/colours/textures and “zero-joint” seamless technologies reflect top interior design trends.

- Trusted by Fortune 500 OEMs: Used globally in iconic furniture brands, proven in millions of square meters of fit-outs.

- Competitive Cost, Responsive Service: Direct-from-manufacturer programs allow you to benefit from volume discounts and tailored technical support.

Discover more and order cutting-edge edge banded solutions for your business.

Email: info@qzseals.com

Phone/WhatsApp: +86-138****8888 (24/7 inquiry & after-sales)

— WoodWeb Furniture Manufacturing Forum | Construction and Building Materials Journal

-

Weather Stripping Door: Enhance Comfort and EfficiencyNewsJul.23,2025

-

The Ultimate Solution for Energy Efficiency: Bottom Seal DoorsNewsJul.23,2025

-

Silicone Seal Strips: Your Solution for a Better SealNewsJul.23,2025

-

Enhance Safety with Anti Slip Stair StripsNewsJul.23,2025

-

Enhance Safety and Aesthetics with Corner Protectors for WallsNewsJul.23,2025

-

Discover the Magic of Silicone Strip Seals for Your GarageNewsJul.23,2025

-

Upgrade Your Seals with Premium Weather StrippingNewsJun.12,2025