Premium Silicone Strip Seal | Durable Weather Stripping

The Indispensable Role of Silicone Strip Seals in Modern Industrial Applications

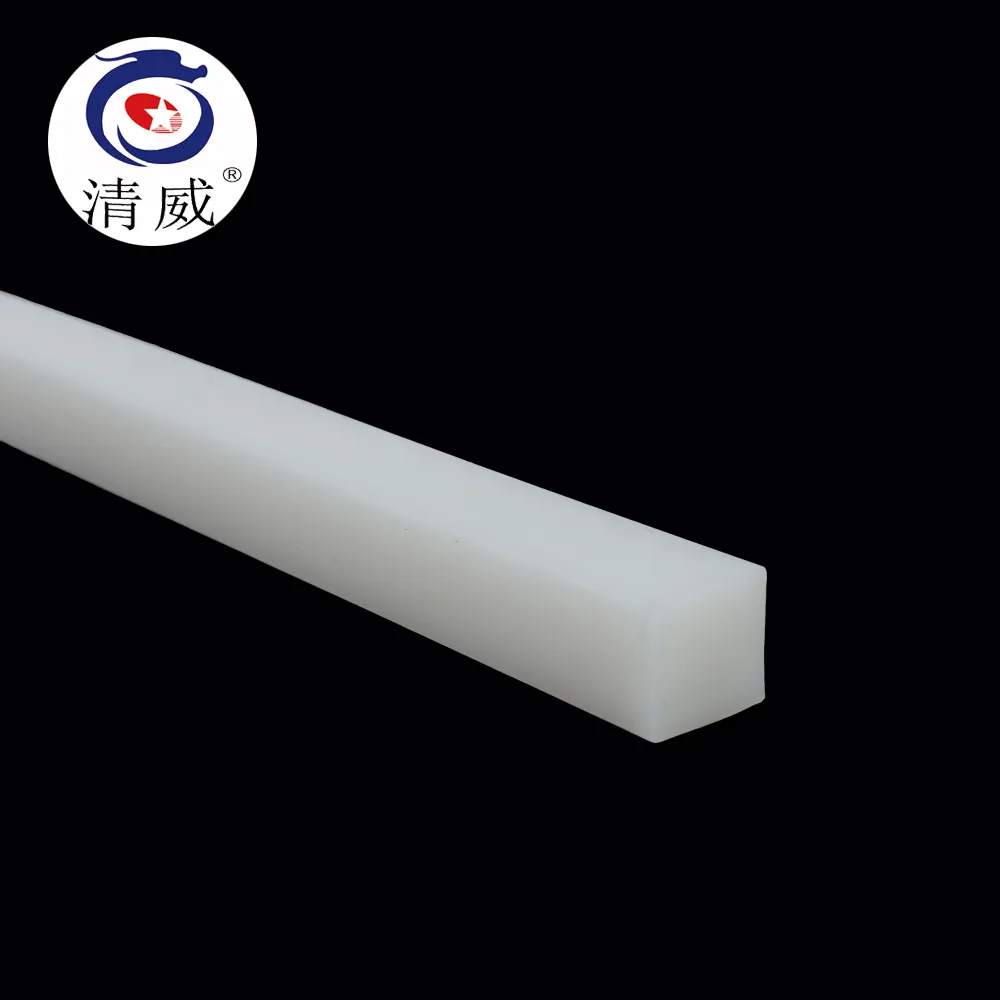

In today’s rapidly evolving industrial landscape, the demand for high-performance sealing solutions is paramount across diverse sectors, driven by stringent regulatory compliance, energy efficiency mandates, and the increasing complexity of operational environments. A critical component addressing these challenges is the silicone strip seal, a versatile product renowned for its exceptional durability, chemical inertness, and ability to withstand extreme temperatures. Industry trends indicate a sustained growth in the market for advanced sealing technologies, with silicone-based solutions gaining significant traction due to their superior performance over traditional rubber materials. For instance, the global market for industrial seals is projected to reach over $18 billion by 2027, with a substantial portion attributed to high-performance elastomers like silicone, fueled by growth in sectors such as automotive, aerospace, healthcare, and electronics where precise sealing and resistance to harsh conditions are non-negotiable. Furthermore, environmental regulations are driving innovation towards materials that offer longer service life and reduce the need for frequent replacement, thereby minimizing waste and operational downtime. The unique molecular structure of silicone, which includes silicon-oxygen bonds, provides inherent resistance to UV radiation, ozone, and a wide array of chemicals, making it an ideal choice for outdoor applications, cleanrooms, and high-purity environments where other materials would degrade rapidly. This resilience directly translates into significant cost savings for businesses by extending equipment lifespan, preventing leaks, and maintaining system integrity, thus underscoring the critical importance of selecting the right sealing solution for any given application. The product, Gap Solid Silicone Rubber Strip Anti Oil High Temp, exemplifies these advantages, offering a robust solution for demanding industrial settings requiring resistance to oils and elevated temperatures.

Unpacking the Technical Specifications and Material Superiority of Silicone Seals

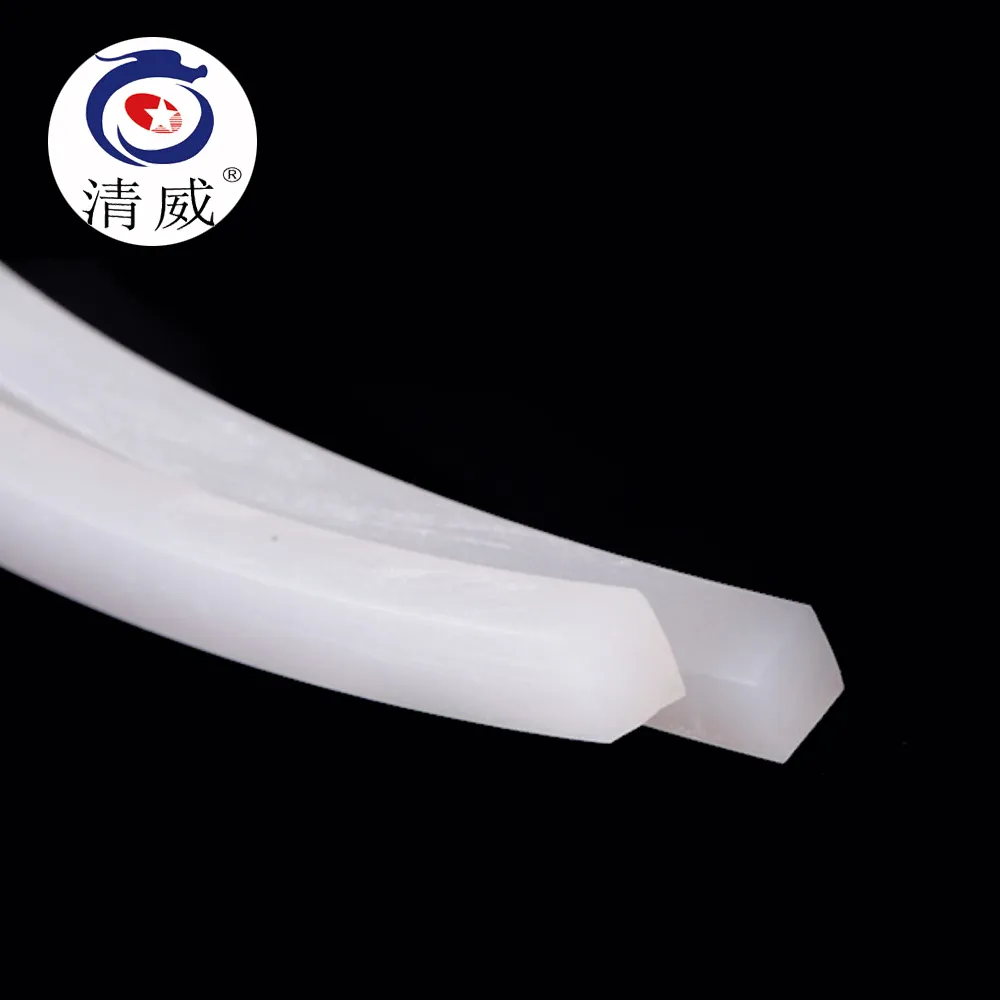

The technical prowess of silicone strip seals stems from their unique material composition and engineered properties, which significantly surpass those of conventional rubber counterparts. Silicone rubber, a synthetic elastomer, is derived from silicon, oxygen, carbon, and hydrogen, offering a distinctive backbone that ensures its exceptional thermal stability, flexibility across extreme temperatures, and excellent dielectric properties. Key technical parameters for these seals typically include a Shore A hardness range often between 30 to 80, providing a balance between flexibility and compression set resistance. For instance, the Gap Solid Silicone Rubber Strip Anti Oil High Temp is engineered to perform reliably from approximately -60°C to +250°C, with intermittent exposure capabilities reaching up to +300°C, making it suitable for applications that experience significant thermal cycling. Its specific resistance to oils, a critical factor in many industrial environments, is achieved through specific compounding, enhancing its performance beyond general-purpose silicones. Furthermore, these seals exhibit low compression set, meaning they retain their elastic properties even after prolonged compression, which is vital for maintaining a continuous seal over time and preventing leaks in dynamic or static applications. The material’s inherent non-toxicity and bio-compatibility also make it indispensable for food-grade, pharmaceutical, and medical applications, adhering to standards like FDA 21 CFR 177.2600. Its resistance to ozone, UV radiation, and weathering ensures longevity in outdoor applications, such as for silicone weather stripping on building facades or industrial equipment exposed to elements. This combination of robust physical and chemical properties guarantees extended service life and reliable performance, translating directly into reduced maintenance costs and enhanced operational efficiency for end-users. The precision in manufacturing and quality control standards applied to these materials ensure that they consistently meet the rigorous demands of specialized industries.

Typical Silicone Strip Seal Parameters

| Parameter | Value Range | Test Standard |

|---|---|---|

| Hardness (Shore A) | 30-80 | ASTM D2240 |

| Tensile Strength | 5-10 MPa | ASTM D412 |

| Elongation at Break | 200-700% | ASTM D412 |

| Operating Temperature Range | -60°C to +250°C (continuous) | Internal Testing |

| Compression Set (22h @ 175°C) | <25% | ASTM D395 Method B |

| Specific Gravity | 1.1 to 1.3 g/cm³ | ASTM D792 |

| Dielectric Strength | 15-25 kV/mm | ASTM D149 |

| Chemical Resistance | Excellent to water, ozone, UV; good to some oils/acids | Various (ISO, ASTM) |

The Advanced Manufacturing Process and Rigorous Quality Control of Silicone Seals

The production of a high-quality silicone strip seal is a multi-stage, precision-driven manufacturing process, predominantly relying on extrusion and calendering techniques, rather than casting, forging, or CNC machining which are typically associated with metal components. It begins with the precise compounding of high-purity silicone polymers with various additives, including reinforcing fillers like fumed silica, pigments for color, and vulcanizing agents (peroxides or platinum catalysts). This compound formulation is critical to achieving specific material properties such as hardness, tensile strength, and oil resistance, tailored for products like the Gap Solid Silicone Rubber Strip Anti Oil High Temp. Once compounded, the material is fed into an extruder, where it is heated and forced through a die to create the desired cross-sectional profile – be it solid, hollow, or complex custom shapes. This continuous extrusion process allows for the production of long, consistent strips. Post-extrusion, the uncured silicone strip undergoes a vulcanization or curing process, typically involving high temperatures in continuous ovens, which cross-links the polymer chains, transforming the soft, pliable material into a durable, elastic rubber. This curing step is vital for setting the final physical properties and ensuring dimensional stability. Following vulcanization, the strips are cooled, cut to specified lengths, and prepared for stringent quality assurance. Our manufacturing facilities operate under strict ISO 9001 quality management systems, ensuring traceability and consistent product quality from raw material to finished good. Each batch undergoes comprehensive inspection, including dimensional checks (using precision calipers and optical scanners), durometer hardness testing (ASTM D2240), tensile strength and elongation testing (ASTM D412), and compression set analysis (ASTM D395). For specialized applications, resistance to specific chemicals, oils, or extreme temperatures is verified through accelerated aging tests and environmental chamber simulations. This meticulous attention to detail and adherence to international standards, including ISO and relevant industry-specific certifications like FDA for food contact materials, guarantee the superior performance and reliability of our silicone products, ensuring they meet or exceed customer expectations and regulatory requirements in sectors like petrochemical, metallurgy, and water/drainage.

Versatile Applications and Unmatched Advantages of Silicone Strip Seals

The unparalleled properties of the silicone strip seal make it an essential component across an exceptionally broad spectrum of industries, providing solutions for sealing, gasketing, cushioning, and insulation. In the construction sector, for instance, these strips are widely utilized as silicone weather stripping for windows and doors, where their excellent resistance to UV, ozone, and extreme temperatures ensures superior thermal insulation, significantly contributing to energy savings by preventing air and moisture infiltration. Similarly, as wood door weather stripping or a silicone door seal strip, they provide an airtight barrier, reducing noise transmission and protecting interiors from dust and pests. Their low compression set means they maintain an effective seal even after years of continuous compression, unlike traditional rubber which can become brittle and lose efficacy. In the automotive industry, silicone seals are critical for engine compartment applications, resisting high temperatures, oils, and automotive fluids, ensuring leak-free performance and extended vehicle life. Within the electronics sector, their superior dielectric properties and resistance to heat are vital for sealing electronic enclosures, protecting sensitive components from environmental factors. The pharmaceutical and food processing industries leverage silicone’s non-toxic, hygienic, and easy-to-clean nature, making it ideal for seals in processing equipment where sterility and chemical resistance are paramount, often meeting stringent FDA and USP Class VI requirements. Beyond these, industrial applications span from sealing furnace doors in metallurgy due to high temperature resistance, to gasketing in petrochemical equipment for chemical compatibility and corrosion resistance, showcasing the energy-saving and anti-corrosion advantages. For instance, a well-implemented door bottom seal rubber strip made of silicone can reduce heating and cooling costs in commercial buildings by up to 15-20% annually by eliminating drafts and heat loss. Our Gap Solid Silicone Rubber Strip Anti Oil High Temp, specifically designed for challenging environments, excels in applications requiring robust oil resistance, such as in hydraulic systems or machinery where traditional silicone might degrade, ensuring longevity and optimal performance. This adaptability and inherent resilience provide a significant return on investment through reduced energy consumption, minimized equipment downtime, and enhanced product integrity across countless critical operations.

Custom Solutions and Unwavering Engineering Support for Your Sealing Needs

Recognizing that off-the-shelf solutions may not always meet the unique and complex demands of specialized industrial applications, our commitment extends to providing comprehensive custom solutions for silicone strip seal requirements, backed by extensive engineering expertise and robust customer support. We understand that optimal performance often hinges on precise fit, specific material properties, and adherence to tight tolerances, which is why our design and production capabilities are geared towards collaborative development. Our experienced engineering team works closely with clients from the initial concept phase, assisting with material selection based on operating environment, temperature extremes, chemical exposure, and mechanical stresses. We leverage advanced CAD/CAM software for precise profile design and simulation, ensuring that the final product, such as a custom silicone door seal strip or a specialized door bottom seal rubber strip, will perform exactly as intended. This collaborative approach minimizes design iterations and accelerates time-to-market for new products or system upgrades. Our production flexibility allows for rapid prototyping and efficient small-batch manufacturing, alongside high-volume production capabilities, ensuring scalability for projects of any size. Beyond manufacturing, our service commitment includes clear communication regarding lead times, which typically range from 2-4 weeks for standard profiles and 4-8 weeks for complex custom designs after tooling approval, depending on order volume and material availability. We stand by the quality of our products with a comprehensive warranty against manufacturing defects for 12 months from the date of purchase, providing peace of mind and demonstrating our confidence in the durability and reliability of our seals. Furthermore, our dedicated customer support team is readily available to provide technical assistance, answer inquiries, and resolve any issues promptly, ensuring a seamless experience from inquiry to post-installation support. This holistic approach to customization, coupled with our steadfast commitment to client success, positions us as a trusted partner in delivering high-performance sealing solutions tailored to the most challenging applications. Our track record includes successful deployment in critical infrastructure projects, demonstrating our capability to deliver on promises and exceed expectations.

Manufacturer Comparison and Our Commitment to Authority and Trust

When selecting a supplier for high-performance silicone strip seals, distinguishing between manufacturers is crucial, as expertise, quality assurance, and reliability vary significantly across the industry. Many providers offer generic silicone products, but true value lies in a manufacturer's proven track record, adherence to international standards, and capacity for innovation and specialized compounding, particularly for demanding applications like those requiring a Gap Solid Silicone Rubber Strip Anti Oil High Temp. Our company differentiates itself through decades of specialized experience in elastomer manufacturing, backed by rigorous certifications and a transparent approach to quality. We hold ISO 9001:2015 certification for our quality management system, underscoring our commitment to consistent product quality and continuous improvement. Furthermore, for applications requiring specific material compliance, our silicone compounds meet critical regulatory standards such as FDA 21 CFR 177.2600 for food contact and REACH/RoHS directives for environmental safety. Our in-house testing laboratory is equipped with state-of-the-art machinery for material characterization, including FTIR spectroscopy for polymer identification, DSC for thermal analysis, and advanced mechanical testing equipment to verify tensile strength, elongation, tear resistance, and compression set according to ASTM standards. This comprehensive testing ensures that every batch of silicone weather stripping or other silicone products delivered meets or exceeds its specified performance criteria. We have established long-term partnerships with leading companies in the petrochemical, food processing, and automotive industries, providing tailored sealing solutions that have consistently outperformed competitors in critical applications. For example, our custom-engineered silicone door seal strip solutions have enabled clients to achieve significant reductions in energy leakage and operational noise levels in highly sensitive environments. We pride ourselves on transparent communication, offering detailed technical data sheets and material safety data sheets (MSDS) for all products, fostering trust and enabling informed decision-making for our B2B clients. Our dedication to research and development allows us to continually innovate, developing new compounds and profiles to address emerging industry challenges, thereby solidifying our position as an authoritative and trustworthy leader in the advanced elastomer sealing market.

Frequently Asked Questions (FAQ) about Silicone Strip Seals

Q1: What are the primary advantages of a silicone strip seal over conventional rubber seals?

Silicone strip seals offer superior performance due to their unique material properties. Unlike conventional rubbers such as EPDM or Neoprene, silicone maintains its flexibility and sealing capabilities across a much broader temperature range, typically from -60°C to +250°C. It exhibits excellent resistance to UV radiation, ozone, weathering, and aging, making it ideal for outdoor and long-term applications without cracking or hardening. Furthermore, silicone has a very low compression set, meaning it retains its original shape and sealing force even after prolonged compression, which is critical for preventing leaks over time. Its inherent non-toxicity and bio-compatibility also make it suitable for medical, food-grade, and pharmaceutical applications where other rubbers cannot be used. While initial cost might be slightly higher, the extended service life and reduced maintenance ultimately provide a lower total cost of ownership, enhancing operational efficiency and reliability in demanding industrial environments.

Q2: Can silicone weather stripping be used in environments with exposure to oils and chemicals?

While general-purpose silicone offers good resistance to many chemicals, its resistance to certain oils, fuels, and solvents can vary. For applications with specific exposure to oils and aggressive chemicals, specialized silicone compounds are formulated. For example, our Gap Solid Silicone Rubber Strip Anti Oil High Temp is specifically designed with enhanced oil resistance through unique compounding, making it highly effective in hydraulic systems, machinery with oil splash, or other industrial settings where traditional silicones might degrade. It's crucial to specify the exact chemical environment during the inquiry process so that we can recommend or custom-engineer a silicone formulation that ensures optimal chemical compatibility and longevity, providing a reliable seal even under challenging chemical exposures, which is vital for maintaining system integrity and preventing costly leaks or component failures.

Q3: What inspection standards do your silicone door seal strips adhere to?

Our silicone door seal strips and all other silicone products are manufactured under stringent quality control protocols, adhering to several international and industry-specific standards to ensure superior performance and reliability. Our facilities are ISO 9001:2015 certified, guaranteeing a robust quality management system throughout the entire production process, from raw material sourcing to final product inspection and dispatch. We conduct comprehensive material testing according to ASTM International standards, including ASTM D2240 for hardness (Shore A), ASTM D412 for tensile strength and elongation, and ASTM D395 for compression set. For specific applications such as food contact or medical devices, our materials can be certified to meet FDA 21 CFR 177.2600 and USP Class VI requirements, respectively. We also ensure compliance with environmental regulations such as REACH and RoHS. This multi-layered approach to quality assurance ensures that every door bottom seal rubber strip or other custom seal you receive meets the highest industry benchmarks, providing confidence in its performance and compliance in critical applications.

Authoritative References

- ASTM International. (Annual). Standard Test Methods for Rubber Property – Durometer Hardness, Tensile Properties, and Compression Set.

- International Organization for Standardization (ISO). (Current). ISO 9001: Quality Management Systems – Requirements.

- U.S. Food and Drug Administration (FDA). (Current). Code of Federal Regulations, Title 21, Part 177: Indirect Food Additives: Polymers.

- The United States Pharmacopeial Convention (USP). (Current). USP General Chapter <88> Biological Reactivity Tests, In Vivo.

- Grand View Research. (2023). Industrial Seals Market Size, Share & Trends Analysis Report.

-

Durable Seal for Oven Door: Perfect Fit, Energy EfficiencyNewsSep.01,2025

-

Durable Silicone Strip Seals: Premium Weather & Door SealingNewsAug.31,2025

-

Premium Seal for Oven Door | Maximize Heat & Energy EfficiencyNewsAug.30,2025

-

Premium Anti Slip Stair Strips: Enhance Safety & Prevent FallsNewsAug.29,2025

-

Clear Corner Protectors: Child Safety for Tables & EdgesNewsAug.28,2025

-

Weather Stripping Door Standard Sizes and Custom CutsNewsAug.12,2025

-

Seal for Oven Door Cleaning and Maintenance TipsNewsAug.12,2025