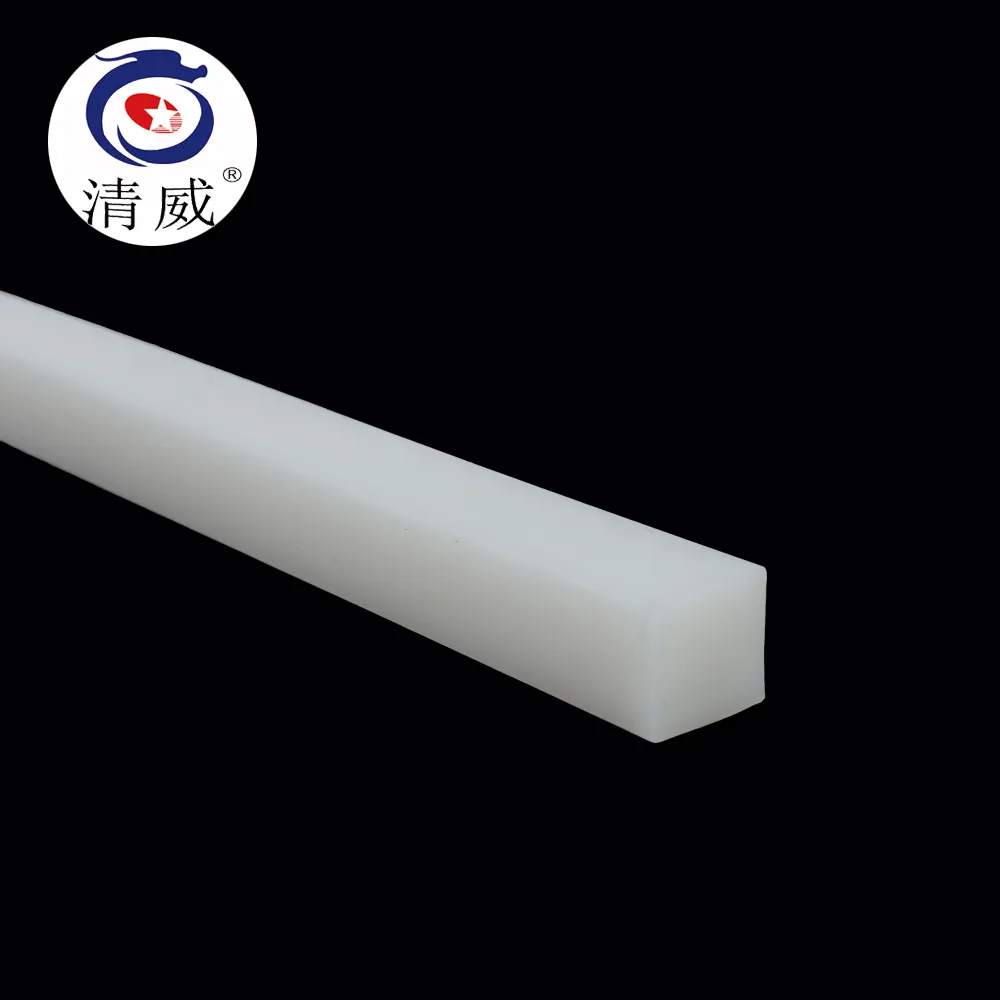

Premium Silicone Strip Seal: Weatherproof Door & Window Sealing

The Indispensable Role of Silicone Strip Seals in Modern Industrial Engineering

In the intricate landscape of modern industrial engineering, the integrity and performance of sealing solutions are paramount, serving as critical components that ensure operational efficiency, safety, and longevity across a myriad of applications. Among these essential elements, the silicone strip seal stands out as a superior choice, renowned for its unparalleled resilience, broad operational capabilities, and exceptional durability. Unlike conventional rubber seals, silicone-based solutions offer distinct advantages, particularly in environments characterized by extreme temperatures, aggressive chemicals, or stringent hygiene requirements. This introduction delves into the fundamental importance of these advanced sealing products, highlighting their pervasive influence from critical infrastructure to sophisticated manufacturing processes. We will explore how a meticulously engineered silicone strip seal, such as the Gap Solid Silicone Rubber Strip Anti Oil High Temp, not only prevents leaks but actively contributes to energy conservation, noise reduction, and enhanced product quality. Its versatility extends across sectors, encompassing everything from intricate electronic enclosures to robust sealing requirements in petrochemical refineries and advanced pharmaceutical facilities. The inherent properties of silicone rubber—its thermal stability, chemical inertness, UV and ozone resistance, and excellent electrical insulation—make it an ideal material for applications where other elastomers simply fall short. Furthermore, the design flexibility inherent in silicone allows for the creation of precise profiles, accommodating complex geometries and demanding installation scenarios. This adaptability ensures optimal performance whether used as silicone weather stripping for architectural envelopes, a robust wood door weather stripping solution, a sophisticated silicone door seal strip in high-traffic commercial buildings, or a durable door bottom seal rubber strip in industrial gateways. Our comprehensive exploration will underscore the technical expertise, rigorous manufacturing standards, and innovative design principles that elevate these components from mere accessories to indispensable guardians of operational integrity, paving the way for a deeper understanding of their critical role in ensuring long-term system reliability and efficiency. This foundational understanding is crucial for B2B decision-makers and technical professionals seeking to optimize their sealing strategies and invest in solutions that offer both immediate performance gains and enduring value. The superior characteristics of silicone, including its non-toxic nature and resistance to fungal growth, further broaden its applicability in sensitive areas like food processing and medical devices, where material purity and hygiene are non-negotiable. The ability of a well-engineered silicone strip seal to maintain its elastic properties and sealing effectiveness across a wide range of temperatures, from sub-zero cryogenic conditions to extreme heat, sets it apart from traditional rubber materials which often become brittle or degrade under such stresses. This robust performance profile minimizes downtime, reduces maintenance costs, and extends the operational lifespan of critical equipment, thereby providing a significant return on investment for industrial applications. The precision required in manufacturing these seals, coupled with advanced quality control measures, ensures that each component consistently meets stringent performance criteria, contributing to the overall reliability and safety of the systems they are integrated into. This commitment to quality and technical excellence is a cornerstone of reliable industrial sealing.

Advanced Material Science: Unpacking the Superiority of Silicone Rubber

The exceptional performance of a silicone strip seal is fundamentally rooted in the unique chemical structure and resulting material properties of silicone rubber, specifically polydimethylsiloxane (PDMS). Unlike organic rubbers, which have a carbon-carbon backbone, silicone rubber possesses a silicon-oxygen backbone (–Si–O–Si–), providing it with an inherent stability that organic polymers cannot match. This inorganic backbone contributes to its remarkable resistance to extreme temperatures, both high and low, making it suitable for applications ranging from cryogenic freezers to high-temperature industrial ovens. Typically, silicone can withstand continuous exposure to temperatures from -60°C to 230°C (-76°F to 446°F), with special grades extending this range even further. Beyond thermal stability, silicone exhibits superior resistance to UV radiation, ozone, and weathering, which are common degradation factors for natural and synthetic organic rubbers. This attribute is particularly vital for outdoor applications like silicone weather stripping, where seals are continuously exposed to environmental elements without compromising their structural integrity or sealing efficacy over time. Furthermore, silicone's chemical inertness is a significant advantage; it does not react with many common chemicals, acids, bases, and solvents, although specific applications require careful material compatibility assessment for aggressive media. Its low compression set means that when a silicone seal is compressed and then released, it returns to its original shape with minimal deformation, ensuring a long-lasting and effective seal even after repeated cycles of compression and decompression. This property is crucial for dynamic sealing applications where maintaining consistent pressure is key to preventing leaks. Silicone also boasts excellent electrical insulation properties, making it an ideal choice for sealing electronic enclosures and protecting sensitive components from moisture and dust ingress. Its non-toxic, hypoallergenic, and bio-compatible nature opens doors for critical applications in the food, beverage, pharmaceutical, and medical industries, where FDA and USP Class VI compliance are often mandatory. For instance, a door bottom seal rubber strip made from FDA-compliant silicone can be safely used in food processing facilities to maintain hygiene and prevent contamination. The surface energy of silicone rubber is also relatively low, which prevents sticking and facilitates easier installation while also offering good release properties in certain molding applications. This comprehensive suite of properties—thermal endurance, environmental resistance, chemical stability, low compression set, electrical insulation, and biological compatibility—collectively elevates silicone rubber as the material of choice for high-performance sealing solutions, setting the benchmark for reliability and longevity in demanding industrial environments. Understanding these intrinsic material advantages is paramount for engineers and procurement specialists evaluating the best sealing solutions for critical applications where failure is not an option and long-term performance is essential. The density of silicone rubber typically ranges from 1.1 to 1.5 g/cm³, depending on the specific formulation and fillers used, which contributes to its robust physical properties.

Precision Manufacturing: The Craftsmanship Behind Every Silicone Strip Seal

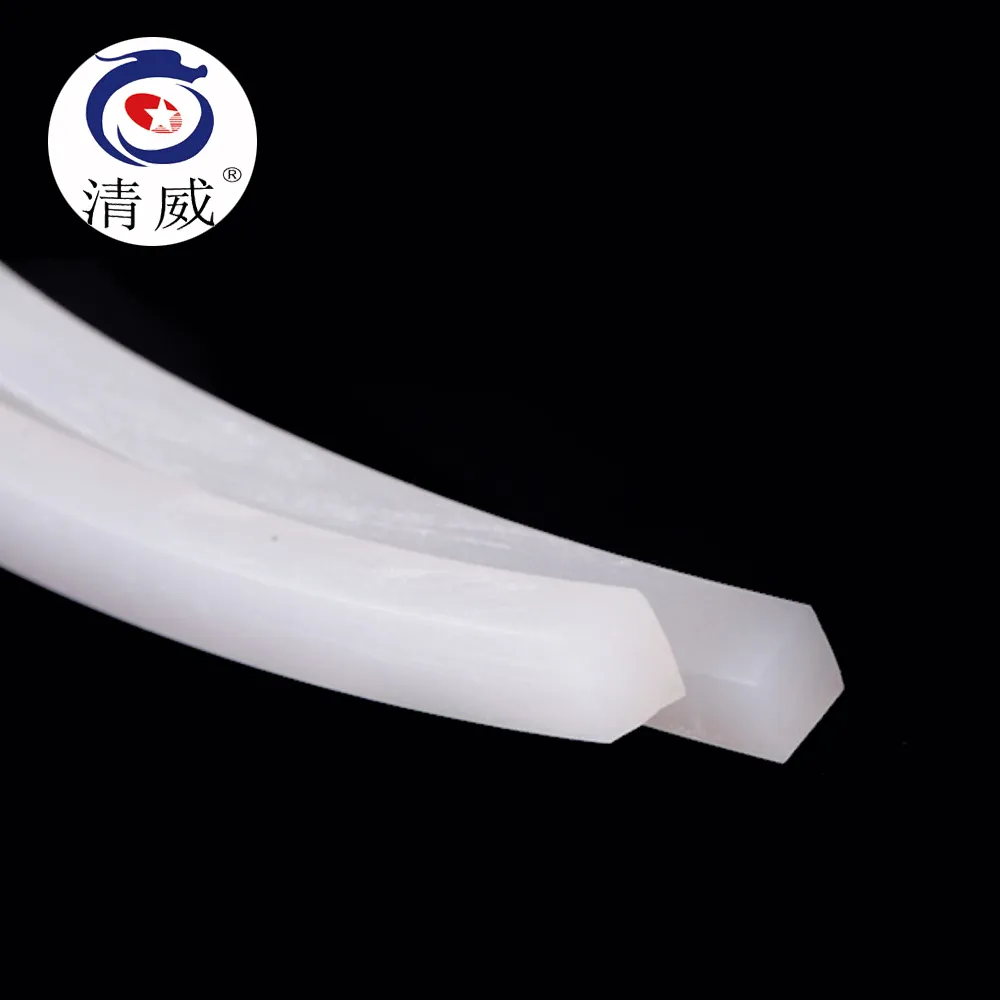

The production of a high-performance silicone strip seal is a meticulous process that combines advanced material science with precision engineering, ensuring each product meets stringent quality and performance specifications. The manufacturing journey typically begins with the careful compounding of raw silicone polymers with various additives, including fillers (like silica for reinforcement), pigments, vulcanizing agents (peroxides or platinum-curing systems), and other processing aids. This compounding process is crucial for achieving the desired physical properties, such as hardness (durometer), tensile strength, elongation, and tear resistance. Once the compound is homogeneously mixed, it proceeds to the shaping phase, which predominantly involves extrusion or compression molding, depending on the desired profile and volume. For continuous profiles like strips, extrusion is the preferred method. In extrusion, the silicone compound is fed into an extruder, where it is heated and forced through a die designed to create the specific cross-sectional shape of the strip. This continuous process allows for the production of long lengths of uniform seals, making it highly efficient for standard and custom profiles used as silicone weather stripping or a silicone door seal strip. Following extrusion, the formed strip undergoes vulcanization, also known as curing, which is a critical chemical process that cross-links the polymer chains, transforming the soft, unvulcanized silicone into a durable, elastic rubber. This curing can occur through various methods, including hot air vulcanization (HAV) in continuous ovens for extruded profiles or compression molding in heated presses for custom shapes and higher precision parts. Post-curing may also be applied, especially for food-grade or medical-grade silicone, to further remove volatile byproducts and enhance properties like low compression set and chemical inertness, ensuring compliance with standards such as FDA 21 CFR 177.2600. Throughout the entire manufacturing process, rigorous quality control measures are implemented. This includes incoming material inspection to verify raw material purity and consistency, in-process checks to monitor dimensional accuracy and surface finish, and final product testing against industry standards like ISO (e.g., ISO 9001 for quality management systems) and ASTM (e.g., ASTM D2000 for rubber products classification). Performance tests may include durometer hardness testing, tensile strength and elongation testing, compression set evaluation, specific gravity measurement, and accelerated aging tests to predict long-term durability. For applications requiring specific performance, such as a wood door weather stripping that must resist extreme temperatures or a door bottom seal rubber strip needing exceptional abrasion resistance, additional testing protocols are applied. Adherence to these strict manufacturing protocols and quality assurance frameworks is what distinguishes a reliable manufacturer, guaranteeing that each silicone strip seal not only meets but often exceeds the demanding requirements of industrial and commercial applications, thereby ensuring safety, efficiency, and longevity in its intended use. This meticulous approach to production is fundamental to delivering products that perform flawlessly under pressure.

Technical Specifications & Performance Metrics: A Deep Dive into Silicone Strip Seal Parameters

For B2B buyers and technical engineers, understanding the precise technical specifications and performance metrics of a silicone strip seal is paramount to selecting the optimal product for their specific application. These parameters provide a quantifiable basis for assessing material quality, operational suitability, and long-term reliability. Key specifications include durometer hardness, tensile strength, elongation at break, tear strength, compression set, and operating temperature range, each offering critical insights into the seal's behavior under various conditions. Durometer hardness, typically measured on the Shore A scale, indicates the material's resistance to indentation, with values commonly ranging from 30A to 80A for silicone seals; a higher number signifies a harder material, which might be preferred for high-pressure applications or those requiring more rigidity, while softer grades are ideal for highly conforming seals or gap filling. Tensile strength, expressed in MPa or PSI, represents the maximum stress a material can withstand while being pulled or stretched before breaking, directly correlating to the seal's robustness under tension. Elongation at break, given as a percentage, measures the extent to which a material can be stretched before it ruptures, indicating its flexibility and ability to accommodate movement without failure, crucial for dynamic seals or those subject to vibration. Tear strength, usually in kN/m or PPI, quantifies the resistance of the material to the propagation of a tear, a vital property for seals that may experience sharp edges or abrasive forces during installation or operation. Compression set is a critical indicator of a seal's long-term sealing effectiveness; it measures the permanent deformation of the material after prolonged compression at a specific temperature. A low compression set percentage means the seal will maintain its original shape and sealing force over time, preventing leaks and ensuring consistent performance, particularly important for static seals like a silicone door seal strip. The operating temperature range defines the thermal limits within which the silicone strip seal can function effectively without degradation, typically ranging from -60°C to 230°C for standard silicones, with special formulations extending beyond these bounds for extreme environments. Furthermore, specific gravity, chemical resistance, and electrical resistivity are also crucial considerations depending on the application. For instance, in petrochemical industries, chemical resistance to specific oils, solvents, or acids is non-negotiable, while in electronics, high electrical resistivity is essential for insulation. A detailed product like the Gap Solid Silicone Rubber Strip Anti Oil High Temp, is designed with these considerations in mind, emphasizing resistance to oils and high temperatures, making it suitable for demanding industrial machinery. Understanding and comparing these technical data points against application requirements enables engineers to make informed decisions, ensuring the selected silicone strip seal provides optimal performance, reliability, and extended service life, ultimately contributing to reduced operational costs and enhanced system integrity. Manufacturers provide comprehensive data sheets to facilitate this crucial selection process, ensuring transparency and aiding in the precise matching of product capabilities to real-world demands.

Typical Silicone Strip Seal Performance Parameters

Versatile Applications: Where Silicone Strip Seals Make the Critical Difference

The adaptability and robust performance of the silicone strip seal position it as an indispensable component across a vast spectrum of industries, where its unique properties solve complex sealing challenges that other materials cannot. In the Petrochemical Industry, for instance, silicone seals are extensively used in piping systems, storage tanks, and various processing equipment. Their exceptional resistance to high temperatures, aggressive chemicals, oils, and fuels makes them ideal for preventing leaks in harsh environments, thus enhancing safety, reducing product loss, and minimizing environmental impact. For high-temperature furnaces and ovens prevalent in the Metallurgy Sector, silicone seals provide reliable thermal barriers, crucial for maintaining energy efficiency and protecting operational personnel from extreme heat. Their ability to withstand continuous high temperatures without losing elasticity ensures a consistent seal in demanding thermal cycling applications. In Water Supply and Drainage Systems, silicone seals are pivotal for ensuring leak-proof connections in pipelines, valves, and pumping stations. Their long-term resistance to water, ozone, and microbial growth, coupled with their non-toxic nature, ensures the integrity of potable water systems and prevents contamination. The construction industry widely adopts silicone weather stripping for windows, doors, and building expansion joints, significantly contributing to energy efficiency by preventing air and moisture infiltration. This application not only reduces heating and cooling costs but also enhances occupant comfort and prolongs the lifespan of building materials by mitigating water damage and mold growth. Similarly, wood door weather stripping and a precisely engineered silicone door seal strip are essential for residential and commercial buildings, providing superior acoustic insulation, dust prevention, and thermal barriers. These seals are critical for maintaining controlled indoor environments, whether it’s a cleanroom requiring stringent particulate control or a sound studio needing optimal acoustic isolation. The use of a robust door bottom seal rubber strip in industrial or commercial settings ensures a tight seal at the threshold, preventing drafts, pest ingress, and dust accumulation, while also contributing to fire safety in some specialized applications. Beyond these major sectors, silicone strip seal finds critical roles in the automotive industry for engine seals and weather seals, in the aerospace industry for lightweight and temperature-resistant seals, in electronics for protecting sensitive components from moisture and dust, and in the food and pharmaceutical industries where FDA and USP Class VI compliant seals ensure hygiene and prevent cross-contamination. Its ability to dampen vibrations and reduce noise further enhances its utility in machinery and equipment, contributing to quieter operations and extended component life. The versatility demonstrated by these diverse applications underscores silicone's status as a premier material for advanced sealing solutions, providing critical benefits such as energy saving, enhanced corrosion resistance, superior thermal insulation, and improved overall system reliability and safety across a broad range of demanding operational contexts.

Customization and Solution Engineering: Tailoring Silicone Strip Seals for Unique Challenges

In many advanced industrial applications, off-the-shelf solutions for sealing needs simply aren't sufficient. This is where the ability to provide custom-engineered silicone strip seal solutions becomes a critical differentiator for manufacturers. A deep understanding of material science, design principles, and application-specific challenges allows leading providers to develop seals that precisely meet unique performance criteria. Customization extends beyond mere dimensions; it encompasses the formulation of the silicone compound, the profile design, color, surface treatment, and integration with other components. For instance, if an application demands a seal with enhanced oil resistance while maintaining high-temperature performance, a specialized silicone compound, potentially including fluorosilicone (FVMQ) for superior chemical resistance, can be engineered. This expertise in material compounding ensures that the silicone strip seal delivers the exact chemical and physical properties required, whether it’s for highly aggressive media in chemical processing or for specific non-stick properties in food handling. Profile design is another crucial aspect of customization. Advanced manufacturing capabilities, including precision extrusion and molding, allow for the creation of complex cross-sectional geometries that optimize sealing effectiveness for specific gaps, pressures, and movements. This might involve multi-cavity designs for improved compression, integrated mounting features for easier installation, or unique bulb and fin configurations for superior sealing against drafts and noise in architectural applications like silicone weather stripping. Consider a scenario where a high-tech cleanroom requires a silicone door seal strip that not only provides an airtight seal but also resists specific cleaning agents and minimizes particle generation. A custom solution would involve a precise profile to fit the door frame, a specific medical/food-grade silicone compound compliant with FDA and USP Class VI standards, and a smooth, non-porous finish to prevent bacterial growth and simplify cleaning. Another example could be a wood door weather stripping solution for a heritage building, where the seal must blend seamlessly with the aesthetic while providing modern thermal performance and preserving the original structure. This would necessitate a custom color matching and a subtle profile designed for discreet integration. The engineering process for custom solutions typically involves a collaborative approach, beginning with detailed consultations to understand the application environment, performance objectives, and regulatory requirements. This is followed by CAD design, prototyping, and rigorous testing, ensuring that the custom silicone strip seal performs flawlessly in its intended application. This consultative and iterative design process minimizes risks, reduces development time, and guarantees that the final product is not just a seal, but an optimized solution engineered for peak performance and longevity in even the most challenging environments. Such bespoke solutions are a testament to advanced manufacturing capabilities and a commitment to solving complex industrial challenges through innovative sealing technology.

Commitment to Excellence: Quality Assurance, Certifications, and Customer Support

The unwavering commitment to quality assurance, stringent adherence to industry certifications, and robust customer support are foundational pillars that define a leading manufacturer of high-performance silicone strip seal solutions. For discerning B2B clients, these aspects provide invaluable assurance of product reliability, compliance, and long-term value. A comprehensive quality assurance (QA) system permeates every stage of the manufacturing process, from raw material procurement to final product delivery. This begins with rigorous incoming material inspection, ensuring that all silicone compounds and additives meet precise specifications and purity standards, often backed by supplier certifications. During the extrusion or molding process of the silicone strip seal, continuous in-process checks are performed to monitor critical parameters such as dimensions, surface finish, and consistency, utilizing advanced laser measurement tools and vision systems to detect any deviations in real-time. Post-production, each batch undergoes a battery of final product tests, including durometer hardness, tensile strength, elongation, tear resistance, and compression set, all conducted in accordance with international standards like ASTM and ISO. For products destined for specialized applications, such as a silicone weather stripping for aerospace or a silicone door seal strip for medical cleanrooms, additional testing for flame retardancy, low smoke emission, or biocompatibility may be performed. Certifications serve as external validation of a manufacturer's quality management system and product compliance. ISO 9001 certification signifies a commitment to internationally recognized quality management principles, ensuring consistent product quality and customer satisfaction through repeatable processes. For seals used in food contact or pharmaceutical applications, FDA 21 CFR 177.2600 compliance is essential, indicating that the silicone material is safe for direct or indirect contact with food and beverages. RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) compliance confirm that the products are free from specific hazardous substances, aligning with global environmental and safety regulations. Reputable manufacturers also often provide detailed material safety data sheets (MSDS) and certificates of conformity for every shipment, enhancing transparency and traceability. Beyond product quality, exceptional customer support is paramount. This includes expert technical assistance during the product selection and design phase, ensuring the right silicone strip seal is chosen for the specific application. Clear communication regarding delivery schedules, lead times, and logistical capabilities is crucial for managing project timelines. A robust warranty policy and responsive after-sales service provide peace of mind, addressing any unforeseen issues promptly and efficiently. This holistic approach, encompassing rigorous QA, comprehensive certifications, and proactive customer support, collectively underscores a manufacturer's dedication to delivering not just a product, but a reliable, compliant, and long-lasting sealing solution that significantly contributes to the operational success and safety of industrial and commercial ventures. This steadfast commitment builds profound trust and establishes enduring partnerships with clients who rely on superior sealing performance.

Frequently Asked Questions (FAQ) about Silicone Strip Seals

Navigating the technical landscape of industrial sealing solutions often leads to specific inquiries from B2B decision-makers and engineers. Here, we address some of the most frequently asked questions regarding the selection, application, and maintenance of silicone strip seal products, aiming to provide clarity and facilitate informed procurement decisions. Q1: What are the primary advantages of silicone strip seals over EPDM or PVC seals? A1: The key advantages of silicone strip seal products lie in their superior temperature range (-60°C to 230°C vs. EPDM's -40°C to 120°C and PVC's -15°C to 60°C), exceptional UV and ozone resistance, which prevents cracking and degradation in outdoor applications, and excellent compression set resistance, ensuring long-term sealing integrity. Silicone is also generally more chemically inert and available in medical/food-grade formulations. EPDM offers good weather resistance but has a narrower temperature range and less resistance to certain oils, while PVC is less flexible, has poorer temperature resistance, and can become brittle over time. For demanding applications such as silicone weather stripping in extreme climates or a door bottom seal rubber strip in a chemical plant, silicone offers unmatched performance and durability, ultimately leading to lower lifecycle costs. Q2: How do I determine the correct hardness (durometer) for my silicone strip seal application? A2: The ideal durometer hardness for a silicone strip seal depends on the specific application's requirements for compression, sealing force, and gap filling. Softer durometers (e.g., 30-50 Shore A) are generally more conformable and suitable for sealing irregular surfaces or requiring minimal closure force, such as a precision silicone door seal strip where a tight yet flexible seal is needed. Harder durometers (e.g., 60-80 Shore A) provide greater resistance to compression and abrasion, making them ideal for high-pressure applications or where the seal needs to withstand significant physical stress, such as in heavy industrial machinery. Consultation with a technical expert from the manufacturer, who can analyze your specific operating conditions, gap dimensions, and desired compression force, is highly recommended to ensure optimal selection. Q3: Are silicone strip seals suitable for outdoor use and direct sunlight exposure? A3: Absolutely. One of the standout features of silicone strip seal products is their exceptional resistance to environmental degradation from UV radiation and ozone, making them highly suitable for prolonged outdoor exposure. Unlike many organic rubbers that degrade, crack, and lose elasticity when exposed to sunlight and atmospheric ozone, silicone maintains its physical properties and aesthetic appearance for decades, making it an excellent choice for applications like wood door weather stripping and exterior building seals. This long-term weatherability significantly reduces replacement frequency and maintenance costs. Q4: What is the typical service life of a silicone strip seal? A4: The service life of a silicone strip seal varies significantly based on the specific operating conditions (temperature, chemical exposure, dynamic vs. static application, compression load) and the quality of the silicone compound. However, due to silicone's inherent stability and resistance to aging, high-quality silicone seals often boast a significantly longer operational lifespan compared to other elastomers, typically ranging from 10 to 20 years or more in moderate conditions. In highly demanding environments, while the lifespan may be shorter, it will still generally outperform alternative materials. Regular inspection and proper installation are key to maximizing longevity. Q5: Can silicone strip seals be customized for specific profiles, colors, or properties? A5: Yes, customization is a major advantage of silicone seals. Leading manufacturers can engineer custom profiles to precisely fit unique geometries, formulate specialized compounds for enhanced properties (e.g., higher oil resistance for the Gap Solid Silicone Rubber Strip Anti Oil High Temp, flame retardancy, electrical conductivity/insulation), and produce seals in a wide range of colors for aesthetic or identification purposes. This bespoke engineering ensures optimal performance for even the most complex or niche applications, allowing for seamless integration and superior functionality in specific industrial designs.

Future Trends and Conclusion: The Enduring Value of Silicone Strip Seals

As industries continue to evolve, driven by demands for greater efficiency, sustainability, and technological advancement, the role of high-performance sealing solutions becomes increasingly critical. The silicone strip seal, with its remarkable array of properties and adaptable nature, is poised to remain at the forefront of this evolution, continually addressing complex sealing challenges across diverse sectors. Future trends in sealing technology are likely to focus on even more specialized silicone formulations, including self-healing silicones for extended longevity, smart seals embedded with sensors for real-time performance monitoring, and advanced composite seals that combine the best attributes of multiple materials to tackle exceptionally harsh or dynamic environments. The push for greater energy efficiency will further solidify the demand for superior insulating seals like advanced silicone weather stripping, while growing environmental regulations will necessitate further development of eco-friendly and fully recyclable silicone compounds. Innovations in manufacturing processes, such as additive manufacturing (3D printing) of silicone, could revolutionize custom seal production, enabling even more complex geometries and rapid prototyping for highly niche applications. The global market for silicone products is projected to grow significantly, fueled by the expanding needs of the automotive, electronics, construction, and healthcare industries, all of which rely heavily on the versatile performance of silicone-based components. This robust growth trajectory underscores the enduring value and increasing importance of solutions like the Gap Solid Silicone Rubber Strip Anti Oil High Temp, which is specifically designed to meet the rigorous demands of industrial use. For B2B stakeholders, investing in high-quality silicone strip seal solutions translates directly into enhanced operational reliability, reduced maintenance costs, improved energy efficiency, and compliance with stringent industry standards. The decision to specify a silicone seal is a strategic one, reflecting a commitment to long-term performance and optimal system integrity. By collaborating with manufacturers who demonstrate deep material expertise, advanced manufacturing capabilities, and a dedication to rigorous quality control, businesses can ensure they procure sealing solutions that not only meet but exceed their most demanding requirements. The ongoing research and development in silicone chemistry and engineering promise even more innovative and specialized solutions in the years to come, solidifying the silicone strip seal's indispensable position in the toolkit of modern industrial engineering. Its superior resistance to environmental factors, coupled with its excellent mechanical properties, ensures that it will continue to be the preferred choice for engineers seeking reliable, long-lasting sealing components that perform exceptionally under pressure. This commitment to continuous innovation and excellence in material science ensures the adaptability and relevance of silicone seals in an ever-changing industrial landscape, providing solutions that support sustainable and efficient operations globally.

References & Further Reading

-

ASTM International - D2000 Standard Classification System for Rubber Products in Automotive Applications

Provides a standard system for specifying rubber materials based on their properties, widely used in various industries for material selection and quality control of products like silicone strip seal.

-

ISO 9001:2015 Quality management systems — Requirements

International standard for quality management, ensuring consistent quality in manufacturing processes, including those for silicone strip seal production.

-

U.S. Food and Drug Administration (FDA) - Code of Federal Regulations, Title 21 (21 CFR 177.2600)

Defines the regulations for rubber articles intended for repeated use in contact with food, critical for food-grade silicone door seal strip applications.

-

Rubber & Plastics News Journal

A leading industry publication offering insights into market trends, material science advancements, and manufacturing innovations in the rubber and plastics sectors, highly relevant for silicone strip seal developments.

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025