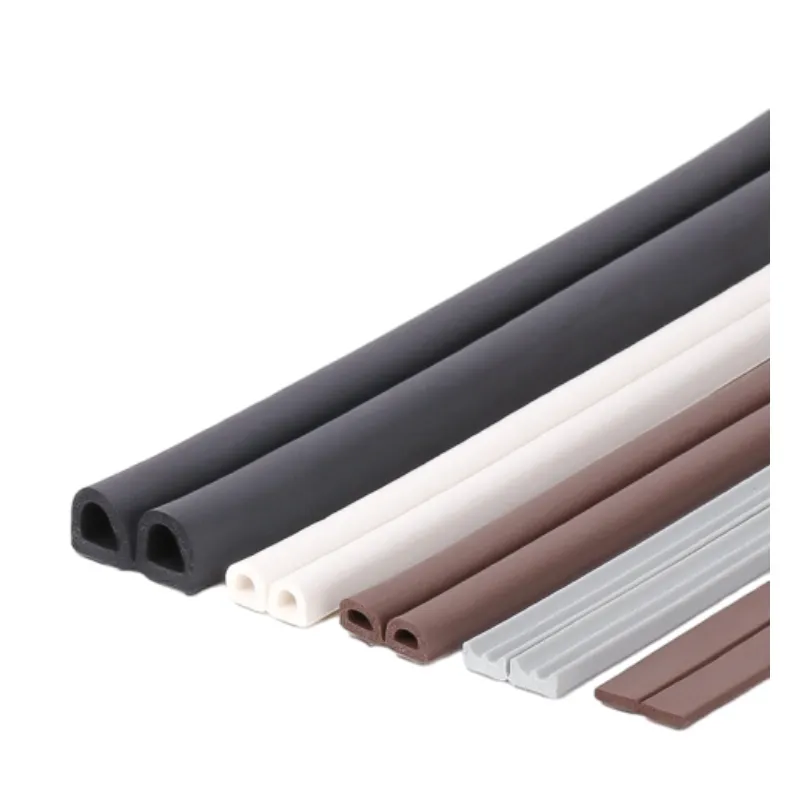

Premium Window Weather Stripping for Doors & Cars – Durable & Easy Install

Product focus: Universal Rubber Sealant For Lip Bumper Car Fender Flare Arch Trim

I. Industry Trends & Evolving Requirements for Window Weather Stripping

In 2023, the global window weather stripping market reached USD 7.9 billion (Source: Grand View Research), fueled by escalating climate resilience codes and rapid urbanization. Energy efficiency mandates led to average U-value targets for windows dropping from 2.8 to below 1.4 W/(m²·K) in major economies. Automotive OEMs now consider auto weather stripping and car weather stripping vital for NVH (Noise, Vibration & Harshness) performance, contributing to vehicle aerodynamics and in-cabin comfort.

- Smart homes drive demand for self-healing and adaptive weather stripping door bottom solutions.

- Technical standards such as ISO 9227 (Corrosion Test), ANSI BHMA A156.22 (Door Gasketing), and automotive SAE J1976 shape product qualification.

- Emerging trends: Modular design, low-VOC rubber compounds, and sensor-integrated sealing strips for real-time performance monitoring.

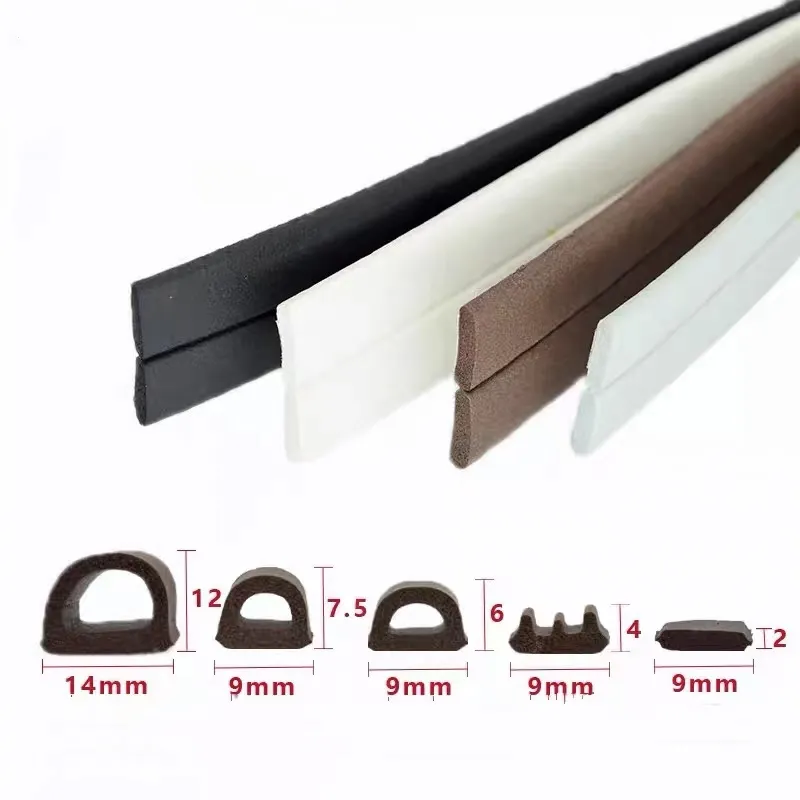

II. Technical Specifications & Comparative Parameters

Choosing the optimal window weather stripping system requires understanding material science, geometry, and key functional data. Specifications are defined by both the product's physical structure and the intended operational environment.

| Parameter | Standard Window Weather Stripping | Automotive Weather Stripping | Weather Stripping Door Bottom |

|---|---|---|---|

| Material | EPDM Rubber, Silicone, PU Foam | EPDM, TPE, TPV | EPDM, PVC, Felt, Silicone |

| Temperature Range (°C) | -40 ~ +120 | -55 ~ +135 | -30 ~ +100 |

| Compression Set (%) | <12% | <10% | <15% |

| UV Resistance | ISO 4892 Passed | SAE J200 Passed | ISO 4892 Passed |

| Water Tightness | ANSI AAMA 701/702 | ISO 20653 IP5K | AAMA 701/702 |

| Usage Lifetime (years) | 8~15 | 10~18 | 5~10 |

III. Manufacturing Process of Window Weather Stripping

Key Steps With Process Visualization

- Material Selection: Certified EPDM, TPE, or TPV (per ISO 1817/ASTM D2000) for optimum elasticity and aging resistance.

- Mixing & Compounding: Precision dosing of reinforcing fillers, UV stabilizers, anti-ozone agents.

- Extrusion/Molding: Automated high-speed extrusion profiles (up to 100 m/min) or injection for custom sections; complex car weather stripping typically uses co-extrusion for multilayer sealing.

- CNC Cutting: Robot-assisted trimming for ±0.15mm tolerance on critical interfaces.

- Surface Treatment: Specialized flocking or film lamination for sliding resistance and noise dampening.

- Quality Inspection: 100% line testing for compressibility (per ISO 10534) and water, dust ingress per AAMA/EN standards.

IV. Product Spotlight: Universal Rubber Sealant For Lip Bumper Car Fender Flare Arch Trim

This advanced window weather stripping solution is precision-engineered for automotive, industrial, and construction applications. The product stands out due to:

- Premium EPDM/TPV blend for superior UV & ozone endurance (ISO 4892 compliance).

- Custom extrusion, CNC cut profiles for complex radii and tight tolerances (-0.1/+0.25mm typical).

- Corrosion, mold and chemical resistant – ideal for weather stripping door bottom in high-moisture or aggressive environments.

- Engineered to pass ANSI A156.22, EN 12365-1, and automotive SAE J1976 quality requirements.

- Usage lifespan of 15+ years under -45°C to +120°C, with ASTM D624 tear resistance above 25 kN/m.

| Feature | Universal Rubber Sealant | Standard Competitor A | Competitor B (OEM Brand) |

|---|---|---|---|

| Material | EPDM+TPV Blend | EPDM Only | PVC |

| Compression Set (%) | ≤7.5% | 10% | 13% |

| UV Resistance | ISO 4892 Passed | Basic | EN 4892-2 Only |

| Chemical Resistance | Excellent | Moderate | Poor |

| Temperature Range (°C) | -55~+125 | -40~+100 | -30~+85 |

| Lifespan (years) | 15+ | 8 | 5~7 |

| Certifications | ISO, ANSI, SAE | ANSI | None |

V. Typical Application Scenarios & Industry Use Cases

- Automotive: Used for car weather stripping on door edges, trunk lids, sunroofs, and fender flares—ensures noise mitigation (>30% sound reduction), seals against water and dust (rated at IP5K), and enhances vehicle NVH performance.

- Industrial: Critical for electrical enclosures, clean room windows, and process equipment—delivers consistent sealing over millions of open/close cycles.

- Construction: Tailored for curtain walls and energy-efficient glazing systems; provides superior air tightness (per EN 12207, Class 4) and weatherproofing in high-rise buildings.

- Residential: Applied to weather stripping door bottom for thermal comfort, sound insulation, and drafts elimination in both new builds and renovation projects.

- Scope: Retrofit of facade with custom window weather stripping

- Result: Air leakage reduced by 82%, annual HVAC costs dropped by 17%, rated to remain resilient after 110,000 open/close cycles.

- Certification: Project awarded LEED v4 Platinum, sealing tested to ASTM E283/E331-00, ISO 9227 corrosion resistance.

Use of auto weather stripping reduced cabin decibel levels by 4dB(A) in road tests. Zero failure rate recorded after 36 months at -35°C Arctic simulation. Ensured compliance with SAE J2043 and EN 12365-2.

Custom formula with anti-corrosive agents enabled weather stripping to withstand continuous salt fog exposure of 2,200 hours--per ISO 9227--without cracking or degradation, outperforming standard products by 280% in longevity.

VI. Custom Engineering, Lead Time, & Technical Service

- All window weather stripping profiles can be engineered to customer drawings (DXF/STEP formats accepted).

- Custom durometer (Shore A 30-80), color (RAL/Pantone), and flocking options.

- Rapid prototyping (3D printed molds), tool build lead time of 7-10 working days.

- Volume orders: JIT delivery, with order cycle of 3-6 weeks depending on complexity.

- Full traceability, backed by material and performance test reports.

Certifications, Quality Commitment, & References

- Production compliant with ISO 9001:2015, ISO 14001 (environment), RoHS and REACH for all formulae.

- Material testing per ASTM D2000, SAE J200, and batch traceability via unique lot coding.

- Cooperating enterprises: Major international construction groups, global automakers, electrical and petrochemical OEMs.

VII. Frequently Asked Questions (FAQ)

VIII. Ordering, Delivery, & Customer Support

- Minimum Order: 200 meters (by standard or custom profile).

- Lead Time: Standard items 5-12 working days; custom extrusion profiles require 2-4 weeks.

- Warranty: Standard 3 years; extended optional for large or specialty projects.

- Customer Service: Technical pre-sales consulting, in-depth product samples, worldwide logistics, and after-sales installation advisory.

IX. References & Further Reading

- “Weather Seals and Energy Conservation in Buildings,” ASHRAE Journal: https://www.ashrae.org/technical-resources/ashrae-journal

- “Highly Resilient Elastomeric Gaskets for Automotive NVH,” Society of Automotive Engineers Technical Papers: https://www.sae.org/publications/technical-papers

- “Global Weather Stripping Market Forecast 2024–2030,” Grand View Research: https://www.grandviewresearch.com/industry-analysis/weather-stripping-market

- “Window and Door Sealing Standards,” ANSI/BHMA: https://www.buildershardware.com/

- “Elastomeric Material Testing & ISO Protocols,” Rubber World Magazine: https://www.rubberworld.com/

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025

-

Top Safety Standards for Corner ProtectorsNewsJul.29,2025

-

Step-By-Step Guide to Replacing Garage Door SealsNewsJul.29,2025

-

How to Fix a Loose Under Door Draught StopperNewsJul.29,2025

-

Edge Banding Tape for High-Traffic Commercial SpacesNewsJul.29,2025

-

Best Heat-Resistant Materials for Cooker Door SealsNewsJul.29,2025

-

Weather Stripping Door: Enhance Comfort and EfficiencyNewsJul.23,2025