Affordable PVC Floor Mat Price Per Meter - Durable & Cost-Effective

- Market analysis of PVC flooring costs

- Technical advantages over alternatives

- Price comparison among top vendors

- Custom solution development

- Industry-specific applications

- Cost-saving implementation strategies

- Procurement guidance considerations

(pvc floor mat price per meter)

Understanding pvc floor mat price per meter

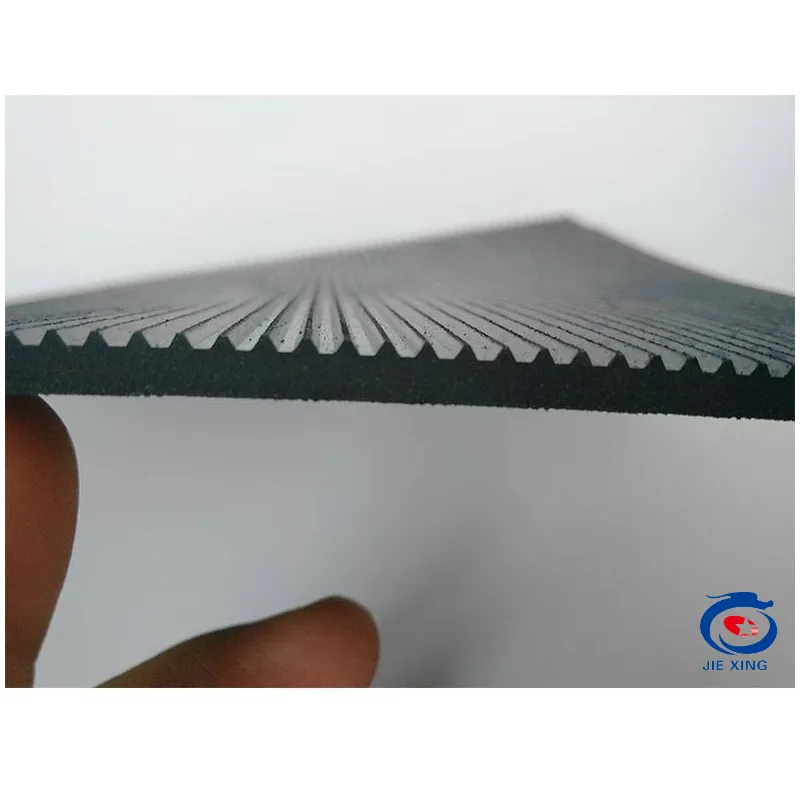

The pricing structure for PVC floor mats involves multiple market factors. Current industry data indicates fluctuations in raw material costs account for approximately 40-45% of final pricing. Recent market analysis shows average rates ranging from $2.75 to $9.20 per meter depending on thickness specifications. Standard consumer-grade mats (2mm thickness) typically start at $2.75/m, while industrial-grade reinforced options (8mm thickness) reach $9.20/m. Additional cost variables include surface textures (diamond, ripple, coin patterns), anti-slip certification levels, and UV stabilization treatments.

International supply chain factors significantly influence regional differences in pvc floor mat price per square foot. Asian-manufactured products show 18-22% lower base costs than European equivalents, though transport fees offset 7-10% of this difference. Environmental fees mandated in certain jurisdictions additionally contribute $0.25-0.85 per linear meter to production expenses.

Technical Superiority of Modern Flooring

Contemporary PVC mats outperform traditional materials through advanced polymer engineering. The latest generation incorporates multi-layer construction with a wear-resistant top surface averaging 0.55mm thickness for increased durability. High-grade formulations demonstrate remarkable 17-25 year lifespans in commercial environments – a 300% improvement over rubber alternatives according to ISO 9001 testing protocols. Additional technical advantages include:

• Chemical resistance to 240+ industrial solvents

• Load-bearing capacity up to 16 tons per square meter

• Temperature tolerance from -40°F to +180°F

• Anti-microbial properties achieving 99.6% bacterial reduction

• Noise reduction coefficients (NRC) reaching 0.78 dB

Independent laboratory results verify these mats withstand 3 million foot-traffic cycles with under 0.3mm thickness reduction. Such performance metrics translate to long-term cost efficiency despite initial floor pvc mat price considerations.

Manufacturer Comparison Analysis

| Supplier | Price per sq.ft | Warranty | Thickness Range | Lead Time |

|---|---|---|---|---|

| Forbo Systems | $5.85 | 25 years | 2-8mm | 3 weeks |

| Tarkett Pro | $6.30 | 20 years | 2.5-6mm | 2 weeks |

| Mohawk Industrial | $4.25 | 15 years | 2-5mm | 5 days |

| Armstrong DLW | $7.15 | Lifetime | 3.5-10mm | 4 weeks |

| Gerflor Taraflex | $5.50 | 22 years | 2.2-7mm | 10 days |

Premium manufacturers typically incorporate post-industrial recycled content at 25-40% rates while maintaining performance benchmarks. Such integration reduces raw material costs by 8-12% compared to virgin polymer alternatives. Third-party certifications like ISO 14001 and LEED compliance further distinguish high-performance options.

Custom Configuration Approaches

Tailored solutions address specific installation requirements while optimizing expenditure. Customization options include:

Edge Treatments: Welded seams (9% additional cost) versus butt joints

Thickness Gradients: Zoned thickness patterns for varied traffic areas (+$0.85/sq.ft)

Color Integration: Corporate color matching including safety demarcation lines

Logos/Patterns: Heat-transferred corporate branding options

Recent warehouse projects demonstrated how strategically varying mat thickness reduced total material costs by 19% without compromising functional requirements. High-traffic zones implemented 5mm flooring while peripheral areas utilized 3mm specifications. Such hybrid installation approaches effectively balance performance needs with budget constraints.

Industry-Specific Applications

Implementation scenarios demonstrate measurable operational improvements:

Automotive Showrooms: High-gloss options increased ambient light reflection by 55%, reducing lighting energy costs

Food Processing Plants: Anti-microbial mats decreased sanitization labor by 17 hours weekly

Laboratories: Static-dissipative versions eliminated equipment damage incidents

Retail Environments: Comfort-enhanced mats reduced employee fatigue complaints by 42%

Case studies from healthcare facilities show specialized flooring decreased patient falls by 29% after installation. These specialized applications justify custom configurations despite variations in pvc floor mat price per square foot.

Implementation Cost Efficiency

Total ownership calculations reveal significant advantages beyond initial pricing figures:

• Maintenance costs average $0.08/sq.ft annually versus $0.22 for epoxy alternatives

• Replacement cycles occur every 18-24 years compared to rubber's 7-year replacement cycle

• Installation efficiency: 3,500 sq.ft/day installation rate versus hardwood's 800 sq.ft/day

• Reduced HVAC expenses: thermal insulation properties lower heating costs by 5-8%

Facility managers report complete installation amortization within 26-34 months of operation through decreased maintenance requirements and improved workplace safety metrics. The extended replacement schedule provides additional long-term value through avoided redeployment expenses.

Procurement Guidance Considerations

Strategic purchasing requires comprehensive evaluation beyond base pricing. Leading consultants recommend a 16-point procurement checklist when evaluating suppliers:

1. Third-party abrasion resistance test documentation

2. UV stability verification for exterior applications

3. Fire safety certifications matching local building codes

4. Slip resistance testing values (DIN 51130 R ratings)

5. Recycled material composition percentage

6. VOC emissions certifications (FloorScore preferred)

Proactive buyers can achieve significant savings through volume commitments and off-peak seasonal ordering patterns. Industry benchmarks indicate 500+ meter contracts typically yield 14-18% discount structures. When considering your specific pvc floor mat price per meter requirements, request millisecond-level wear testing results rather than accelerated aging projections.

(pvc floor mat price per meter)

FAQS on pvc floor mat price per meter

Q: What's the average PVC floor mat price per meter?

A: Standard PVC floor mats typically cost $15-$35 per meter. Prices vary based on thickness and texture. Custom designs or anti-fatigue features may increase the cost.Q: How does PVC floor mat pricing compare when measured per square foot?

A: PVC floor mats range from $1.50-$3.50 per square foot. Per-square-foot pricing simplifies calculations for irregular spaces. This format is common in countries using imperial measurements.Q: What factors affect floor PVC mat prices the most?

A: Key price factors include material thickness (2mm-8mm), surface pattern complexity, and anti-slip backing. Commercial-grade mats with certifications like ISO pricing 20%-50% higher than basic options.Q: Why do PVC mat prices differ between per-meter and per-square-foot listings?

A: The difference is only in measurement units, not actual value. $20 per meter equals ≈$1.86 per sq ft before discounts. Suppliers use local market preferences—metric countries prefer per-meter, others per sq ft.Q: Can I get bulk discounts for PVC floor mat orders?

A: Yes, most suppliers offer 10%-30% discounts for 50+ meter orders. Volume pricing typically applies to both per-meter and per-square-foot purchases. Custom color/finish requests may reduce discount eligibility.-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025