Telephone: +8618730949119

E-mail: 1299343081@qq.com

Feb . 15, 2025 10:03

Back to list

pvc edge banding tape

PVC edge banding tape plays a crucial role in the furniture and interior design industries, embodying a blend of functionality, aesthetics, and long-lasting quality. For those unfamiliar, edge banding is a process of applying veneer or tape to cover the exposed edges of materials like plywood, particle board, or MDF, offering not just a polished finish, but also enhancing durability.

In terms of authoritativeness, the endorsement of PVC edge banding by industry leaders and professionals is a testament to its efficacy. Top furniture manufacturers incorporate PVC edge banding as a standard practice. Reputed organizations such as the American Furniture Manufacturers Association (AFMA) acknowledge its importance in ensuring product quality and customer satisfaction. Furthermore, green certifications and compliance with stringent environmental regulations highlight PVC's evolving role in sustainable practices. As sustainability becomes pivotal in material selection, companies have begun developing eco-friendly, recyclable PVC tapes, reinforcing commitment to responsible manufacturing. Trustworthiness is equally paramount when discussing PVC edge banding. The material's proven track record garners trust among consumers and manufacturers alike. Businesses and DIY enthusiasts prioritize products that are backed by positive reviews and industry certifications. Many suppliers provide detailed product specifications and usage guides, demystifying the installation process. Reputable brands offer warranties and customer support services, ensuring users that they can rely on their purchase. Engaging with customer feedback and continually innovating products further bolsters consumer confidence. This trust, built on quality and performance, establishes PVC edge banding as a foundational element in design and construction. In conclusion, PVC edge banding tape is not just a supplementary accessory in furniture production; it stands as a testament to modern manufacturing's blend of art and science. Its widespread application underscores an industry trust built over decades, supported by continual advancements in technology and a commitment to quality. For designers, manufacturers, and consumers seeking a reliable, aesthetically pleasing, and practical solution to edge finishing, PVC edge banding remains an unrivaled choice, synonymous with excellence and reliability in the domain of interior aesthetics and functionality.

In terms of authoritativeness, the endorsement of PVC edge banding by industry leaders and professionals is a testament to its efficacy. Top furniture manufacturers incorporate PVC edge banding as a standard practice. Reputed organizations such as the American Furniture Manufacturers Association (AFMA) acknowledge its importance in ensuring product quality and customer satisfaction. Furthermore, green certifications and compliance with stringent environmental regulations highlight PVC's evolving role in sustainable practices. As sustainability becomes pivotal in material selection, companies have begun developing eco-friendly, recyclable PVC tapes, reinforcing commitment to responsible manufacturing. Trustworthiness is equally paramount when discussing PVC edge banding. The material's proven track record garners trust among consumers and manufacturers alike. Businesses and DIY enthusiasts prioritize products that are backed by positive reviews and industry certifications. Many suppliers provide detailed product specifications and usage guides, demystifying the installation process. Reputable brands offer warranties and customer support services, ensuring users that they can rely on their purchase. Engaging with customer feedback and continually innovating products further bolsters consumer confidence. This trust, built on quality and performance, establishes PVC edge banding as a foundational element in design and construction. In conclusion, PVC edge banding tape is not just a supplementary accessory in furniture production; it stands as a testament to modern manufacturing's blend of art and science. Its widespread application underscores an industry trust built over decades, supported by continual advancements in technology and a commitment to quality. For designers, manufacturers, and consumers seeking a reliable, aesthetically pleasing, and practical solution to edge finishing, PVC edge banding remains an unrivaled choice, synonymous with excellence and reliability in the domain of interior aesthetics and functionality.

Next:

Latest news

-

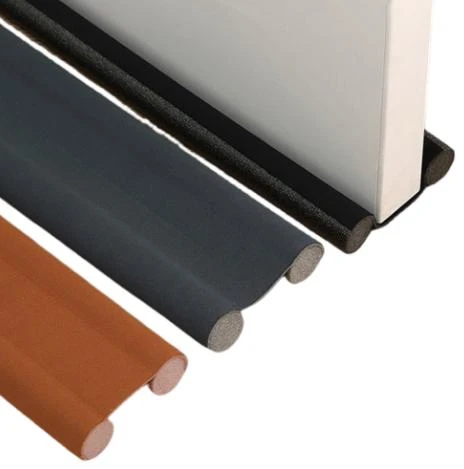

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025