pvc edge tape suppliers

Finding the Best PVC Edge Tape Suppliers

In the realm of modern manufacturing and furniture production, PVC edge tape has emerged as an essential component for enhancing the aesthetics and durability of various products. As a popular choice for edging surfaces made of particleboard, MDF, and other composite materials, PVC edge tape provides not only a refined finish but also protective qualities. For manufacturers and furniture makers, sourcing high-quality PVC edge tape is crucial. This article will explore how to find reliable PVC edge tape suppliers and what factors to consider during the selection process.

Understanding PVC Edge Tape

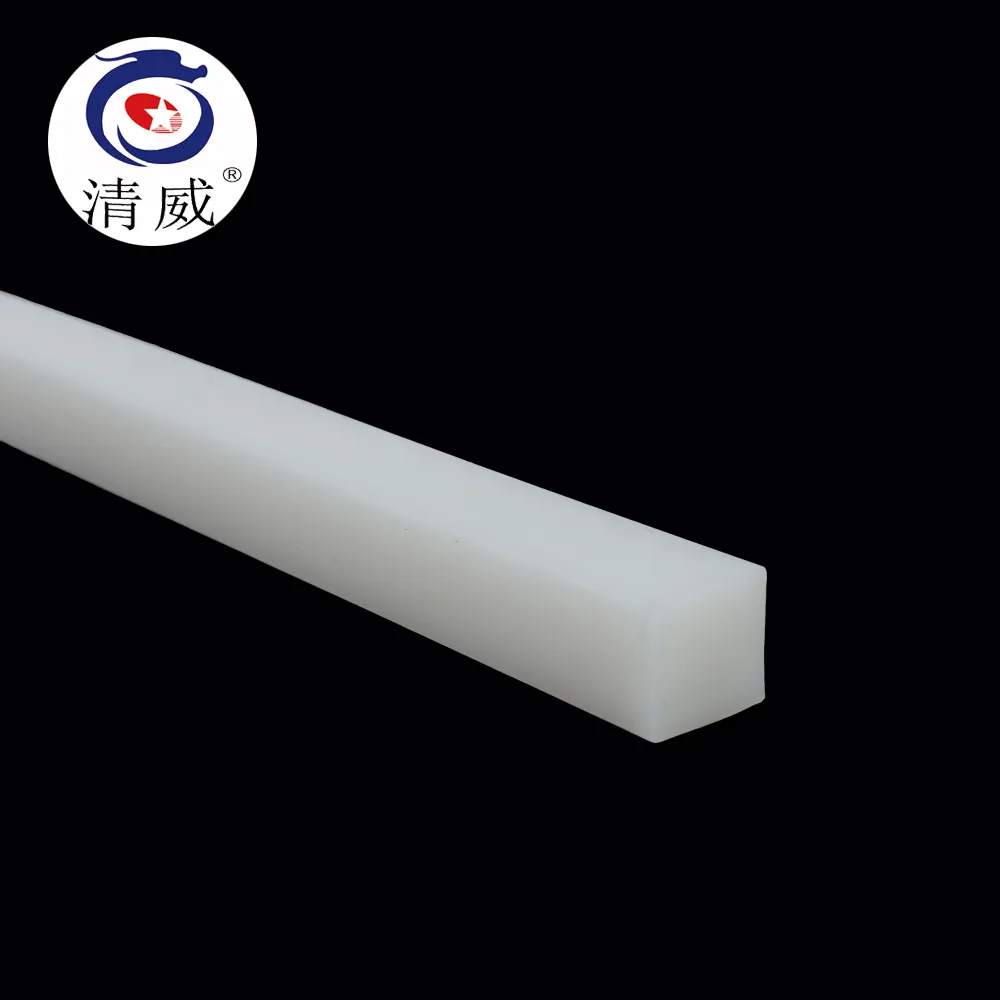

PVC (polyvinyl chloride) edge tape is widely used to cover the raw edges of materials, particularly in cabinetry and furniture production. It serves multiple purposes protecting the edges from moisture, wear, and abrasion while also improving the overall appearance of the product. PVC edge tape is available in various colors, widths, and thicknesses, making it a versatile choice for different design requirements.

Why Quality Matters

Choosing high-quality PVC edge tape is paramount for ensuring that the final product meets customer expectations. Poor-quality tape can peel, discolor, or fail to adhere properly, leading to increased costs and customer dissatisfaction. Therefore, it's important to partner with reputable suppliers who understand the nuances of the material and its application.

Finding Reliable Suppliers

When seeking PVC edge tape suppliers, consider the following steps

1. Research and Recommendations Start by conducting online research to identify potential suppliers. Look for reviews and testimonials from other manufacturers. Recommendations from industry peers can also provide valuable insights into reliable suppliers.

pvc edge tape suppliers

2. Evaluate Product Range A good supplier should offer a wide variety of PVC edge tape options, including different colors, finishes, and adhesive strengths. This variety ensures that you can find the right product to match your specific requirements.

3. Assess Quality Standards Check if the supplier adheres to recognized quality standards. Certifications such as ISO can be a good indicator of a supplier's commitment to quality. Request samples of PVC edge tape to evaluate the thickness, adhesion, and finish.

4. Consider Pricing and MOQ While price is an important factor, it should not be the sole criterion for choosing a supplier. Obtain quotes from multiple suppliers to find a balance between cost and quality. Additionally, inquire about the minimum order quantity (MOQ) to ensure it aligns with your business needs.

5. Examine Customer Support A reliable supplier should have excellent customer service. This includes being responsive to inquiries, providing product guidance, and handling any concerns that may arise during the order process. Good communication can make a significant difference in your overall experience.

6. Delivery and Logistics Assess the supplier's delivery capabilities. Timely delivery is crucial for maintaining production schedules. Ensure that the supplier can meet your lead times and offers reasonable shipping options.

7. Sustainability Practices As sustainability becomes increasingly important, consider suppliers that prioritize eco-friendly practices. This includes using recyclable materials or producing edge tape with lower environmental impacts.

Conclusion

The search for reliable PVC edge tape suppliers is an important step for any business involved in furniture production or manufacturing. By understanding the significance of quality, conducting thorough research, and considering various factors such as product range, pricing, and customer service, manufacturers can find the right partners to support their business needs. Ultimately, investing time in selecting the right PVC edge tape supplier will lead to better products, increased customer satisfaction, and sustained growth in the competitive market.

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025