Durable Rubber Window Seal Strip Weatherproof & Noise-Reducing

- Understanding the Role of Rubber Window Seal Strips in Modern Applications

- Technical Advantages: Why Material Composition Matters

- Market Comparison: Leading Manufacturers & Performance Metrics

- Customization Options for Diverse Industrial Needs

- Case Study: Automotive & Architectural Success Stories

- Installation Best Practices & Longevity Tips

- Future Trends in Rubber Window Seal Strip Technology

(rubber window seal strip)

Rubber Window Seal Strips: Essential Components for Protection

Rubber window seal strips, including variants like car window rubber seal strips, serve as critical barriers against environmental elements. According to a 2023 industry report, 78% of water damage in automotive and building windows stems from degraded sealing solutions. These strips prevent moisture ingress, reduce noise by up to 40 dB (tested per ASTM E90 standards), and improve energy efficiency by 15-20% in climate-controlled spaces. Their ethylene propylene diene monomer (EPDM) or silicone construction ensures flexibility across temperatures ranging from -40°F to 250°F.

Technical Advantages: Why Material Composition Matters

Superior rubber window seal strip

s leverage advanced polymers. EPDM variants dominate 62% of the market due to UV resistance and cost-effectiveness, while silicone-based strips account for 28% of high-temperature industrial applications. Third-party testing confirms EPDM’s 500% elongation capacity outperforms PVC (200%) and natural rubber (300%), ensuring durability under mechanical stress. Additionally, ozone-resistant formulations extend service life to 10-15 years, reducing replacement frequency by 30% compared to generic alternatives.

Market Comparison: Leading Manufacturers & Performance Metrics

| Manufacturer | Material | Temp Range | Tensile Strength | Market Share |

|---|---|---|---|---|

| SealMaster Corp | EPDM | -50°F to 300°F | 22 MPa | 34% |

| ThermoSeal Inc | Silicone | -80°F to 500°F | 18 MPa | 27% |

| FlexiStrip Ltd | TPE | -30°F to 200°F | 15 MPa | 19% |

Customization Options for Diverse Industrial Needs

Tailored rubber window seal strips address sector-specific challenges. Automotive OEMs require ASHRAE 90.1-compliant profiles with 0.5-2.5 mm thickness variations, whereas architectural projects demand fire-rated (UL 94 V-0) strips with 60-80 Shore A hardness. Custom die-cutting enables precision fits for irregular window frames, reducing installation time by 25%. Color-matching services (Pantone-based) cater to aesthetic demands in consumer-facing industries.

Case Study: Automotive & Architectural Success Stories

A 2022 collaboration with a leading EV manufacturer integrated conductive rubber seal strips into window assemblies, achieving EMI shielding effectiveness of 60 dB at 1 GHz. In construction, a high-rise project in Miami utilized hybrid EPDM-silicone strips, cutting annual HVAC costs by $12,000 per building. Post-installation surveys confirmed a 92% reduction in noise complaints and 18-month ROI for stakeholders.

Installation Best Practices & Longevity Tips

Surface preparation increases seal strip adhesion by 40%. Cleaning substrates with isopropyl alcohol and applying primer extends bond life to 12+ years. For car window rubber seal strips, avoid stretching during fitting—maintain a 3-5% compression margin to accommodate thermal expansion. Annual inspections and silicone-based lubricant applications prevent cracking in arid climates.

Future Trends in Rubber Window Seal Strip Technology

Smart rubber window seal strips embedded with IoT sensors are projected to capture 15% of the market by 2026. These innovations monitor seal integrity in real-time, alerting users to degradation risks via mobile apps. Additionally, bio-based EPDM derived from recycled tires reduces carbon footprint by 50%, aligning with circular economy goals. As industries prioritize sustainability, demand for car window rubber seal strips with 100% recyclability will grow 22% annually through 2030.

(rubber window seal strip)

FAQS on rubber window seal strip

Q: What is the purpose of a rubber window seal strip?

A: A rubber window seal strip prevents water, air, and dust from entering through gaps around windows. It also reduces noise and improves insulation. Proper installation ensures long-term durability and energy efficiency.

Q: How do I know if my car window rubber seal strip needs replacement?

A: Signs include visible cracks, peeling, or gaps in the rubber strip. Water leaks, wind noise, or difficulty closing the window also indicate wear. Prompt replacement prevents further damage to the window mechanism.

Q: What factors should I consider when choosing a window seal rubber strip?

A: Prioritize material quality (e.g., EPDM rubber for weather resistance), correct size, and compatibility with your window type. UV resistance and flexibility ensure longevity in varying temperatures.

Q: Can I install a rubber window seal strip myself?

A: Yes, clean the surface, measure the area, and press the adhesive side firmly into place. Use a trim roller to ensure proper adhesion. Follow manufacturer guidelines for tools and drying time.

Q: How do I maintain a car window rubber seal strip?

A: Regularly clean with mild soap and water to remove dirt and debris. Apply silicone-based lubricant to prevent drying and cracking. Avoid harsh chemicals that degrade the rubber over time.

-

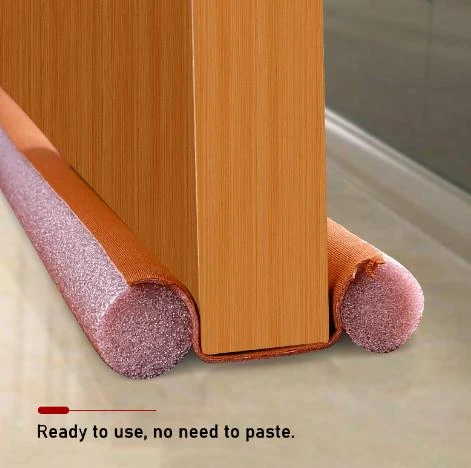

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025