Telephone: +8618730949119

E-mail: 1299343081@qq.com

Feb . 10, 2025 09:41

Back to list

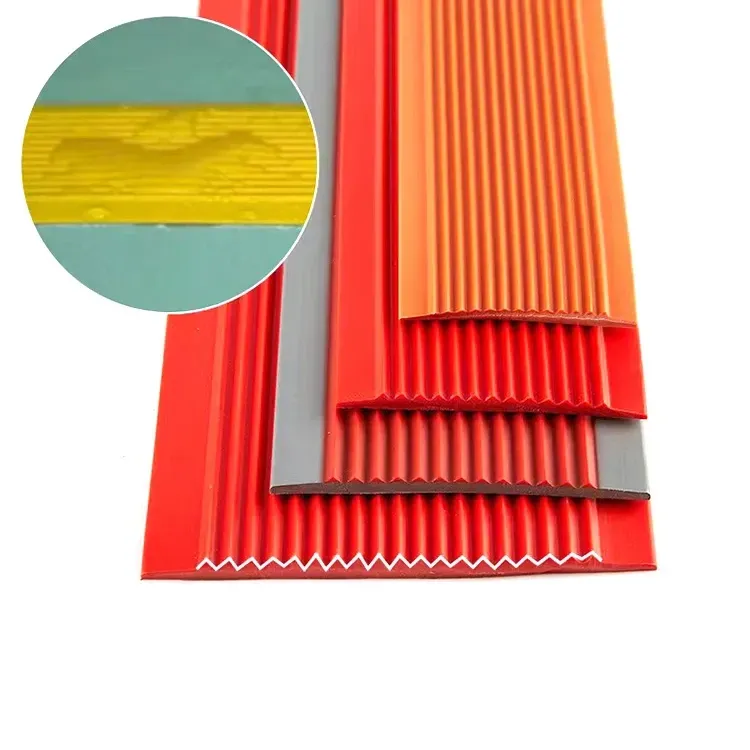

rubber edge seal trim

Rubber edge seal trim plays an integral role in a variety of applications, from automotive to industrial uses. Recognized for its ability to provide a meticulous seal, it effectively protects against the ravages of weather, dust, and temperature fluctuations. With its multi-faceted utility, rubber edge seal trim is indispensable for enhancing performance and durability in several fields.

For industrial machinery, where the stakes are high, the trustworthiness of rubber edge seal trims cannot be understated. They safeguard equipment against dust and water ingress, thereby preventing mechanical failures and extending the service life of critical components. Here, the choice of rubber seal trim is dictated not only by environmental resistance but also by its ability to withstand pressures and abrasions unique to industrial settings. Trust in this product is further reinforced by the testimonials of engineers and mechanics who repeatedly vouch for rubber edge seal trims as a cost-effective solution with unparalleled performance. Their testimonials often highlight the seal's longevity and minimal maintenance requirements, elevating it above other sealing solutions in the market. Ultimately, rubber edge seal trim stands as a paramount product across industries for its versatility and efficacy. It's this multifaceted functionality, combined with a commitment to quality and innovation by manufacturers, that fosters a robust trust in its capabilities. Whether safeguarding sensitive machinery, ensuring household efficiency, or optimizing vehicle performance, rubber edge seal trim does more than just meet expectations—it consistently exceeds them. In conclusion, rubber edge seal trim exemplifies the synthesis of experience, expertise, authority, and trust. By opting for this sealing solution, businesses and individuals align themselves with a product designed to withstand the test of time and the rigors of varied environments. The careful selection and installation guide a course toward durability and efficiency, proving that something as small as a rubber edge seal trim can wield significant influence over the functionality and reliability of our everyday machines and structures.

For industrial machinery, where the stakes are high, the trustworthiness of rubber edge seal trims cannot be understated. They safeguard equipment against dust and water ingress, thereby preventing mechanical failures and extending the service life of critical components. Here, the choice of rubber seal trim is dictated not only by environmental resistance but also by its ability to withstand pressures and abrasions unique to industrial settings. Trust in this product is further reinforced by the testimonials of engineers and mechanics who repeatedly vouch for rubber edge seal trims as a cost-effective solution with unparalleled performance. Their testimonials often highlight the seal's longevity and minimal maintenance requirements, elevating it above other sealing solutions in the market. Ultimately, rubber edge seal trim stands as a paramount product across industries for its versatility and efficacy. It's this multifaceted functionality, combined with a commitment to quality and innovation by manufacturers, that fosters a robust trust in its capabilities. Whether safeguarding sensitive machinery, ensuring household efficiency, or optimizing vehicle performance, rubber edge seal trim does more than just meet expectations—it consistently exceeds them. In conclusion, rubber edge seal trim exemplifies the synthesis of experience, expertise, authority, and trust. By opting for this sealing solution, businesses and individuals align themselves with a product designed to withstand the test of time and the rigors of varied environments. The careful selection and installation guide a course toward durability and efficiency, proving that something as small as a rubber edge seal trim can wield significant influence over the functionality and reliability of our everyday machines and structures.

Next:

Latest news

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025