rubber edge trim seals

The Importance of Rubber Edge Trim Seals

Rubber edge trim seals are essential components in various industries, providing a protective and aesthetic finish to exposed edges and surfaces. These seals are designed to protect edges from damage, enhance safety, and improve the overall visual appeal of products. Whether used in automotive applications, furniture manufacturing, or industrial machinery, rubber trim seals play a crucial role in extending the life of materials and ensuring operational efficiency.

Understanding Rubber Edge Trim Seals

Rubber edge trim seals are typically made from high-quality rubber materials, including EPDM (Ethylene Propylene Diene Monomer), PVC (Polyvinyl Chloride), or silicone. These materials are chosen for their durability, flexibility, and resistance to weathering, UV radiation, and extreme temperatures. The ability of rubber to withstand various environmental conditions makes it an ideal choice for edge protection.

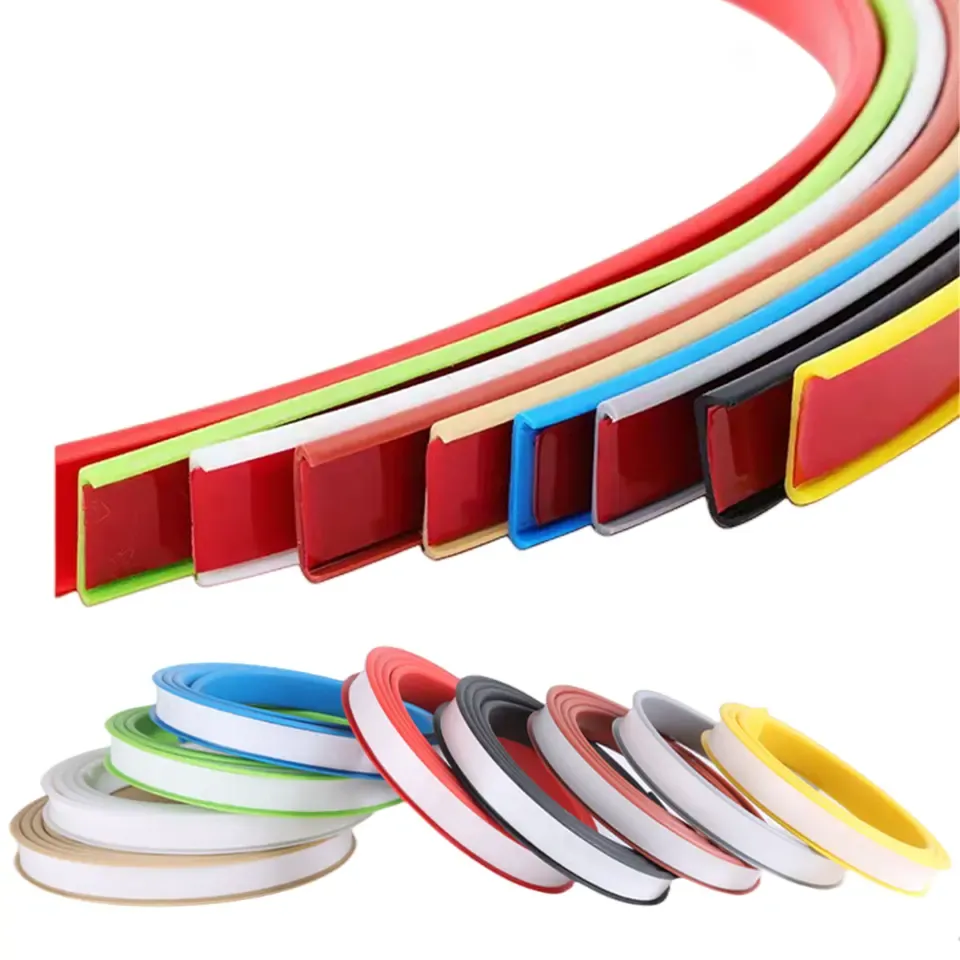

These seals come in a variety of shapes and sizes, including U-shaped, L-shaped, and T-shaped profiles, allowing for versatility across different applications. They can be installed on a wide range of surfaces, such as metal, glass, wood, and plastic, making them a universal solution for edge protection.

Key Benefits of Rubber Edge Trim Seals

1. Protection Against Damage One of the primary functions of rubber edge trim seals is to protect the edges of various materials from chipping, cracking, or fraying. This is particularly important in areas where products are frequently handled or where sharp edges pose a risk of injury.

2. Enhanced Safety By covering sharp edges, rubber trim seals contribute to a safer working environment. They minimize the risk of cuts and injuries to personnel, making them a vital safety feature in industrial settings, commercial kitchens, and home furniture.

rubber edge trim seals

3. Aesthetic Appeal In addition to their protective qualities, rubber edge trim seals enhance the visual appeal of products. They provide a finished look that can elevate the overall design of an item, whether it’s a car door, kitchen counter, or industrial machinery. The various colors and textures available ensure that they can match or complement the existing materials.

4. Noise Reduction Rubber has inherent sound-dampening properties, making edge trim seals useful in reducing noise when closing doors or cabinets. This is particularly beneficial in environments where noise reduction is a priority, such as offices and residential spaces.

5. Easy Installation Many rubber edge trim seals are designed for easy installation, often featuring adhesive backing or simple clip-on mechanisms. This ease of installation can save time and labor costs, making them a practical choice for manufacturers and DIY enthusiasts alike.

Applications Across Industries

Rubber edge trim seals are used in numerous sectors, including automotive, construction, electronics, and appliance manufacturing. In the automotive industry, for instance, they are commonly found around doors, windows, and trunk lids to provide a weatherproof seal, enhance aesthetics, and improve aerodynamics.

In the realm of furniture design, rubber edge trim is used on tables, cabinets, and workstations to prevent wear and tear on exposed edges, protecting against moisture and damage from daily use.

Conclusion

In summary, rubber edge trim seals serve multiple purposes, from protecting edges to improving safety and aesthetics. Their versatility and effectiveness make them a staple in various industries, enhancing both functionality and design. Whether you're an industrial manufacturer or a DIY enthusiast, incorporating rubber edge trim seals into your projects can yield significant benefits, ensuring longevity and safety while enhancing the overall appearance.

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025