Flexible Rubber Gasket Strips for Leak-Proof Sealing Solutions in Various Applications

Understanding Rubber Gasket Strips Essential Components for Sealing Applications

Rubber gasket strips are critical components used in a variety of industries to ensure effective sealing between two surfaces. They are designed to prevent the leakage of fluids and gases, making them essential in manufacturing, automotive, aerospace, and plumbing applications. In this article, we will explore the features, benefits, types, and applications of rubber gasket strips, shedding light on why they are indispensable in modern engineering and construction.

What is a Rubber Gasket Strip?

A rubber gasket strip is a flexible strip made from various types of rubber materials, designed to fill the gap between two mating surfaces. These strips come in varying widths and thicknesses, depending on the specific sealing requirements. The primary function of a gasket strip is to form a barrier that prevents the escape of liquids or gases, thus maintaining pressure and integrity within mechanical systems.

Features and Benefits

1. Flexibility and Compression One of the most important features of rubber gasket strips is their flexibility. This allows them to conform to uneven surfaces, creating a tight seal that minimizes the risk of leaks. When compressed between two surfaces, the rubber can deform slightly, ensuring that it fills any gaps.

2. Resistance to Chemicals and Temperature Rubber gaskets can be formulated from different types of rubber, including neoprene, EPDM, and silicone, each tailored for specific applications. These materials provide excellent resistance to a wide range of chemicals and extreme temperatures, making them suitable for use in harsh environments.

3. Durability Quality rubber gasket strips are designed to withstand wear and tear, ensuring a long service life. They are resistant to aging, UV radiation, and ozone, which can degrade other materials over time.

4. Cost-Effective Solutions Compared to other sealing methods, rubber gasket strips offer a cost-effective solution for preventing leaks and ensuring safety in mechanical operations. Their easy installation further reduces labor costs.

Types of Rubber Gasket Strips

There are several types of rubber gasket strips available, each serving specific needs

1. Solid Rubber Gasket Strips Made from a single piece of rubber, these strips are ideal for applications where a robust seal is necessary. They are often used in heavy machinery and large-scale industrial applications.

rubber gasket strip

2. Foam Rubber Gasket Strips These strips contain air pockets, which make them lighter and more compressible. They are best suited for applications requiring low pressure.

3. TPE (Thermoplastic Elastomer) Gasket Strips TPEs combine the benefits of rubber and plastic, providing excellent durability, resistance to chemicals, and versatility in applications.

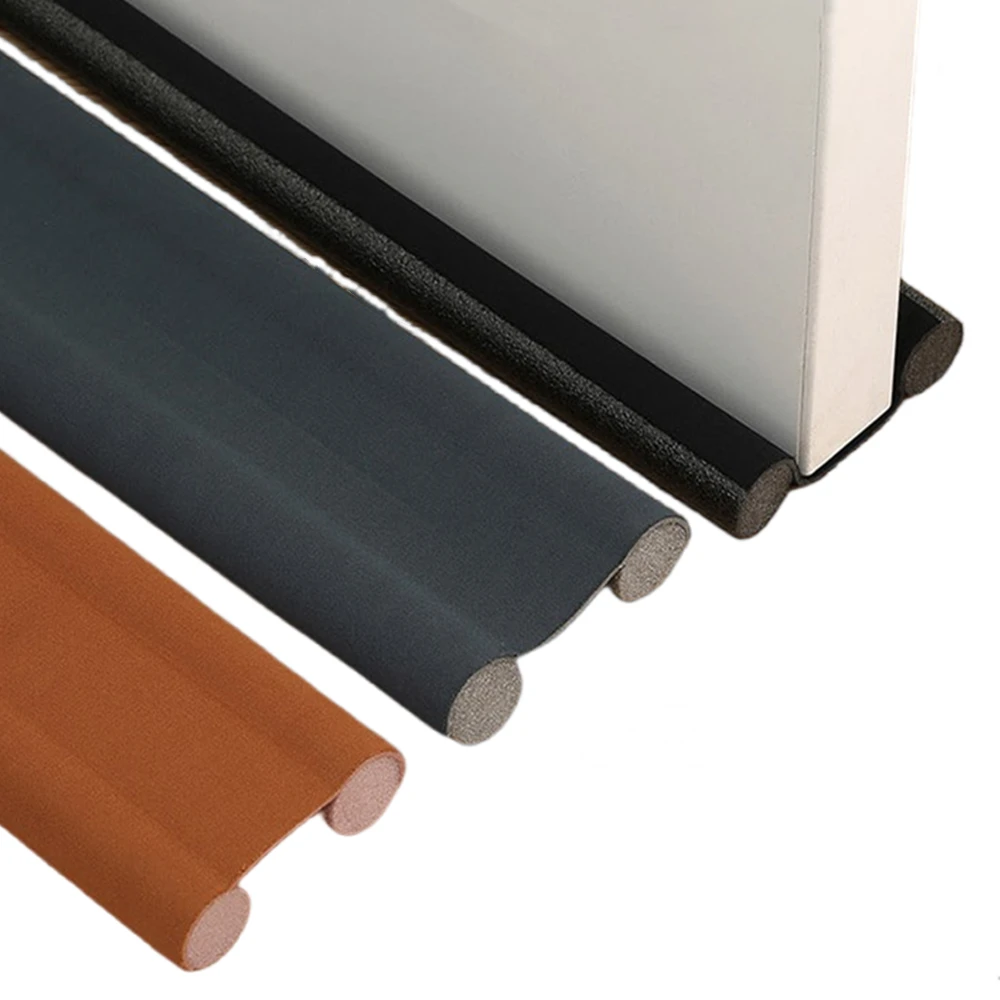

4. Self-Adhesive Gasket Strips These strips come with an adhesive backing, allowing for easy and quick installation without additional adhesives or mechanical fasteners.

Applications

Rubber gasket strips are used in a multitude of industries, including

- Automotive In vehicles, rubber gaskets are used in engines, transmissions, and doors to prevent fluid leaks and keep out dirt and moisture.

- Aerospace Gasket strips are critical in sealing fuel systems and hydraulic lines, ensuring safety and performance under extreme conditions.

- Construction In buildings, rubber gaskets are used around windows, doors, and other fixtures to provide weatherproofing and insulation.

- Manufacturing Many industrial machines rely on rubber gasket strips to prevent leaks of oils and other fluids, ensuring efficient operation.

- HVAC Systems Rubber gaskets are pivotal in heating, ventilation, and air conditioning systems to maintain proper airflow and temperature regulation.

Conclusion

Rubber gasket strips are essential components in a wide range of applications, offering flexibility, durability, and resistance to various environmental factors. Their ability to create effective seals between surfaces makes them invaluable in preventing leaks and ensuring the safe and efficient operation of machinery and systems. As industries continue to advance, the demand for high-quality rubber gasket solutions is likely to grow, highlighting their critical role in engineering and manufacturing processes. Understanding the properties and applications of rubber gasket strips can help engineers and manufacturers choose the most suitable products for their specific needs, leading to better performance and reliability in their operations.

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025