Telephone: +8618730949119

E-mail: 1299343081@qq.com

Jan . 30, 2025 05:02

Back to list

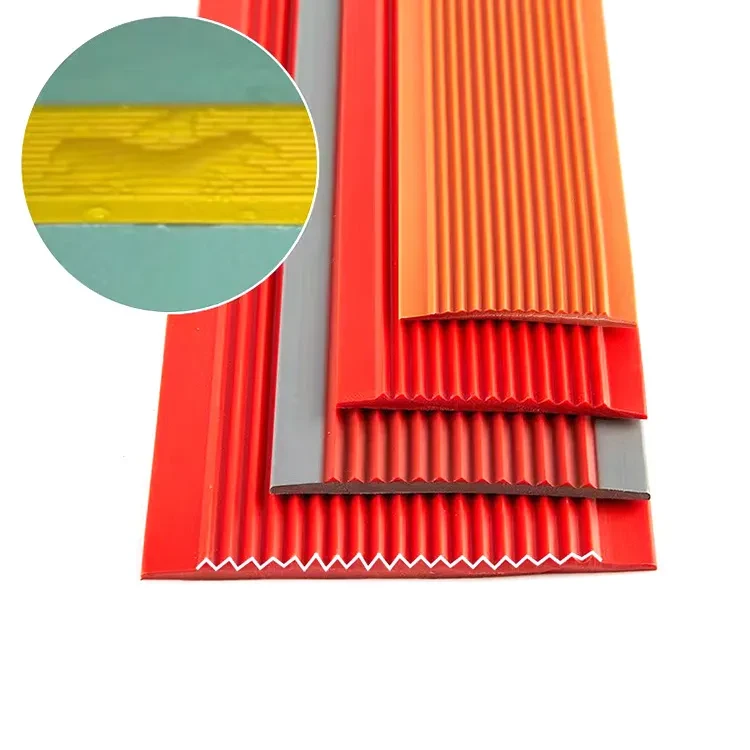

rubber strip for door seal

Rubber strips for door seals have become a ubiquitous necessity in both residential and commercial settings, providing an essential barrier against the elements and improving energy efficiency. This seemingly simple product carries a substantial weight of responsibility for various infrastructural needs.

Manufacturers strive to uphold a strong reputation for quality, often undergoing rigorous testing to meet industry standards and certifications – ES and ISO compliance serving as benchmarks. Clients can trust in these certifications as markers of excellence and reliability. As consumer awareness grows, there is a noticeable pivot towards sustainable product options. Opting for high-quality, long-lasting door seals reduces waste over time, a factor increasingly important as we move towards more environmentally conscious consumer habits. Manufacturers are responding by utilizing advanced technologies in production to reduce the environmental impact, such as recycling offcuts and minimizing waste outputs. For someone scouting rubber strips for door seals, the breadth of choice offers numerous benefits, from soundproofing and insulation to durability and aesthetic appeal. High-grade options like silicone may present an alternative when additional flexibility and extreme temperature resilience are required, though typically at a higher cost than EPDM. Ensuring trustworthiness, a select number of manufacturers offer warranties and customer service guarantees that allow consumers to purchase with confidence, knowing that they stand by the performance and quality of their products. In summary, rubber strips for door seals are not just functional commodities but represent a sophisticated confluence of material science and practical application. Selecting the right product involves understanding its material advantages, application methods, and the certification standards it meets. As the industry evolves, the role of rubber door seals in enhancing energy efficiency, promoting sustainability, and providing reliable, durable solutions becomes ever more significant, marking them as indispensable in modern building frameworks.

Manufacturers strive to uphold a strong reputation for quality, often undergoing rigorous testing to meet industry standards and certifications – ES and ISO compliance serving as benchmarks. Clients can trust in these certifications as markers of excellence and reliability. As consumer awareness grows, there is a noticeable pivot towards sustainable product options. Opting for high-quality, long-lasting door seals reduces waste over time, a factor increasingly important as we move towards more environmentally conscious consumer habits. Manufacturers are responding by utilizing advanced technologies in production to reduce the environmental impact, such as recycling offcuts and minimizing waste outputs. For someone scouting rubber strips for door seals, the breadth of choice offers numerous benefits, from soundproofing and insulation to durability and aesthetic appeal. High-grade options like silicone may present an alternative when additional flexibility and extreme temperature resilience are required, though typically at a higher cost than EPDM. Ensuring trustworthiness, a select number of manufacturers offer warranties and customer service guarantees that allow consumers to purchase with confidence, knowing that they stand by the performance and quality of their products. In summary, rubber strips for door seals are not just functional commodities but represent a sophisticated confluence of material science and practical application. Selecting the right product involves understanding its material advantages, application methods, and the certification standards it meets. As the industry evolves, the role of rubber door seals in enhancing energy efficiency, promoting sustainability, and providing reliable, durable solutions becomes ever more significant, marking them as indispensable in modern building frameworks.

Next:

Latest news

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025