Telephone: +8618730949119

E-mail: 1299343081@qq.com

Feb . 13, 2025 09:45

Back to list

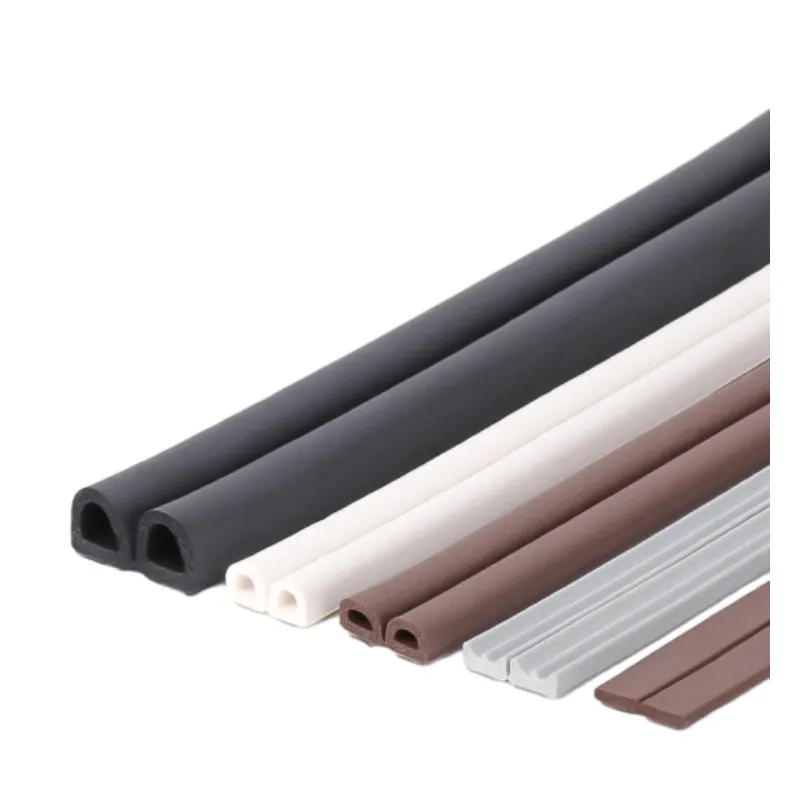

rubber window weatherstrip

Rubber window weatherstrips are indispensable in modern building and automotive industries for their remarkable ability to seal gaps, block out elements, and enhance energy efficiency. The growing demand for environment-friendly and cost-effective solutions is leading property owners and automotive manufacturers to focus more on these specialized rubber components. Here’s an insightful exploration, backed by years of expertise, into why rubber window weatherstrips are crucial and how to ensure they serve you with optimal performance.

Authoritativeness in this sector stems from understanding both the macro and micro environmental impacts of rubber weatherstrips. First, consider their contribution to sustainable building practices. A certified green building or environment-friendly vehicle often employs cutting-edge weatherstripping technology to minimize environmental footprints. The advancement of recyclable materials in rubber manufacturing adds to their eco-friendly credentials. Trustworthiness in weatherstrip performance is fortified by adherence to stringent manufacturing standards, ensuring reliability and safety. For example, ASTM (American Society for Testing and Materials) standards provide guidelines that ensure these products can endure rigorous operating conditions over their service life. Trusted brands often highlight their compliance with such standards as a mark of quality. Maintaining rubber window weatherstrips is equally vital. Regular inspection for tears, detachment, or deformation can prevent minor issues from escalating into major problems. Cleaning weatherstrips with mild detergent and water can enhance their lifespan, ensuring the rubber maintains its elasticity and sealing properties. In conclusion, the integration of rubber window weatherstrips is not just a pragmatic choice, but a strategic one that combines economic, environmental, and comfort benefits. This synthesis of experience, expertise, authority, and trustworthiness makes them essential components in both residential and automotive settings. Whether you are an architect designing energy-efficient spaces or an automobile engineer aiming for quieter and more efficient vehicles, understanding the nuances of rubber weatherstripping will invariably contribute to superior outcomes.

Authoritativeness in this sector stems from understanding both the macro and micro environmental impacts of rubber weatherstrips. First, consider their contribution to sustainable building practices. A certified green building or environment-friendly vehicle often employs cutting-edge weatherstripping technology to minimize environmental footprints. The advancement of recyclable materials in rubber manufacturing adds to their eco-friendly credentials. Trustworthiness in weatherstrip performance is fortified by adherence to stringent manufacturing standards, ensuring reliability and safety. For example, ASTM (American Society for Testing and Materials) standards provide guidelines that ensure these products can endure rigorous operating conditions over their service life. Trusted brands often highlight their compliance with such standards as a mark of quality. Maintaining rubber window weatherstrips is equally vital. Regular inspection for tears, detachment, or deformation can prevent minor issues from escalating into major problems. Cleaning weatherstrips with mild detergent and water can enhance their lifespan, ensuring the rubber maintains its elasticity and sealing properties. In conclusion, the integration of rubber window weatherstrips is not just a pragmatic choice, but a strategic one that combines economic, environmental, and comfort benefits. This synthesis of experience, expertise, authority, and trustworthiness makes them essential components in both residential and automotive settings. Whether you are an architect designing energy-efficient spaces or an automobile engineer aiming for quieter and more efficient vehicles, understanding the nuances of rubber weatherstripping will invariably contribute to superior outcomes.

Latest news

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025