Seal Rubber Edge Trim for Enhanced Protection and Durability in Various Applications

The Importance of Seal Rubber Edge Trim in Modern Applications

In various industries, the necessity for effective sealing solutions cannot be overstated. One of the most versatile and efficient options available is the seal rubber edge trim. This product serves as an essential component in ensuring that various types of machinery and constructions maintain their integrity, energy efficiency, and safety.

What is Seal Rubber Edge Trim?

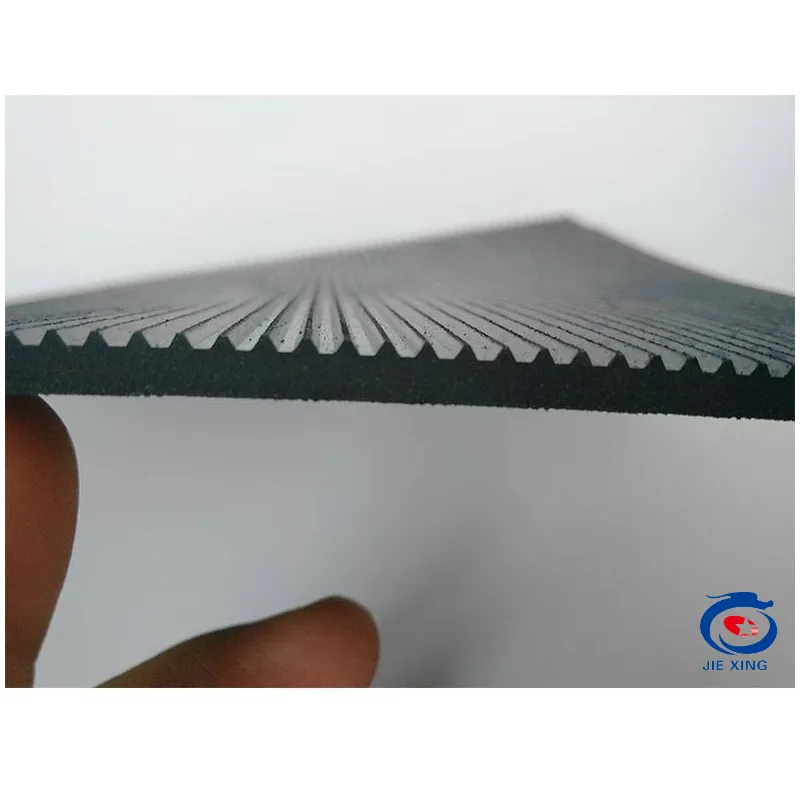

Seal rubber edge trim is a flexible and durable material designed to be installed along the edges of surfaces or objects to provide a sealing effect. Typically made from high-quality rubber or thermoplastic elastomer, it is engineered to resist a range of environmental factors including temperature fluctuations, moisture, and harsh chemicals. The primary purpose of the edge trim is to fill gaps and spaces, thereby minimizing the risk of leaks, drafts, and contamination.

Applications Across Various Industries

1. Automotive Industry In automotive manufacturing, seal rubber edge trims are critical for door seals, hood seals, and trunk seals. They prevent water and dust from entering the vehicle, ensuring a comfortable environment for passengers and protecting sensitive components. Their ability to isolate noise also enhances the driving experience.

2. Construction and Architecture In construction, edge trims are utilized around windows, doors, and roofing. This application protects against water ingress, thereby prolonging the life of the building and enhancing energy efficiency. In commercial and residential settings, proper sealing can significantly reduce heating and cooling costs, making buildings more sustainable.

3. Appliances and Electronics Seal rubber edge trims are also found in household appliances, such as refrigerators and washing machines, where they function as door seals. They help to maintain temperature and prevent leaks, which is crucial for both performance and energy savings. In electronics, edge trims protect internal components from environmental damage and contribute to overall construction stability.

seal rubber edge trim

4. Industrial Equipment Many types of industrial machinery require sealing solutions to ensure optimal performance. Whether it’s a press, conveyor, or any machinery that involves moving parts, the implementation of rubber edge trim can prevent abrasive contact, minimize vibrations, and reduce the amount of dirt and debris that can affect machinery efficiency.

Benefits of Using Seal Rubber Edge Trim

- Durability Made from robust materials, rubber edge trims can withstand high levels of wear and tear in challenging environments, making them a reliable choice for a variety of applications.

- Customizability Seal rubber edge trims can be molded into different shapes and sizes, allowing for customized solutions tailored to the specific needs of a project. This adaptability makes them suitable for both large-scale industrial applications and small personal projects.

- Easy Installation The flexible nature of rubber edge trims allows for simple and effective installation. They can often be attached using adhesive or mechanical fasteners, which saves time and labor costs.

- Cost-Effectiveness While initial investment costs may vary, the long-term benefits of using seal rubber edge trim, such as reduced maintenance costs and improved energy efficiency, often outweigh these costs. Proper sealing solutions can lead to significant savings over time.

Conclusion

The role of seal rubber edge trim in contemporary applications is undeniable. From automotive to construction and industrial settings, its importance in providing seclusion from environmental factors is crucial for maintaining operational efficiency and prolonging the life of components and structures. As industries continue to seek effective sealing solutions to improve energy efficiency and performance, rubber edge trims will undoubtedly remain a staple in engineering and manufacturing disciplines. Organizations looking to enhance their product’s reliability and durability should consider incorporating seal rubber edge trims into their designs, paving the way for innovation and sustainability in their operations.

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025