Telephone: +8618730949119

E-mail: 1299343081@qq.com

Jan . 28, 2025 02:16

Back to list

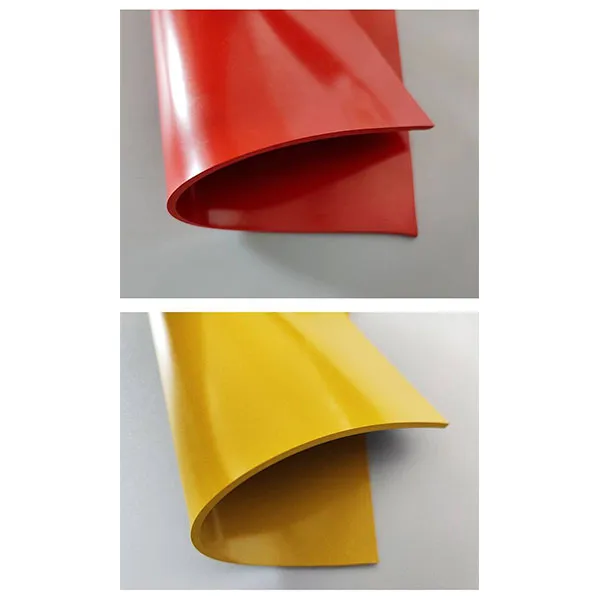

seal strips

Seal strips play a pivotal role in numerous industries due to their essential function in reducing energy costs, improving durability, and enhancing product longevity. Possessing expertise in understanding and applying seal strips can dramatically influence their effectiveness in various applications. This article delves deeply into the unique insights of using seal strips, drawing from documented experiences, expert advice, authoritative insights, and reputable practices that assure trustworthy results.

Innovative trends further enhance the value proposition for seal strips. The advent of smart seal strips that offer IoT integrations to monitor efficiency can shift paradigms. Imagine a home where seal strips provide data analytics on energy savings or signal when replacement is due. This synergy of technology and traditional products could redefine user interaction and engagement with everyday items. Enhancing a seal strip's efficacy also dwells heavily on proper installation practices. Professional installers stress the significance of cleaning the surface prior to installation to ensure adhesive bonding is optimal. Neglecting this step could lead to premature failure or diminished sealing capability. Users are advised to follow manufacturer instructions rigorously or employ professional services to guarantee the installation is executed flawlessly. Finally, the maintenance of seal strips is equally critical to prolong their effectiveness. Routine inspections to check for wear and tear, especially in high-traffic areas or harsh environments, can preemptively address potential failures. Simple actions such as seasonal cleanings or reapplication of adhesive can significantly extend the product lifecycle. In conclusion, seal strips offer substantial benefits when chosen and used correctly. This comprehensive understanding of seal strips, integrating personal experiences, expert material selection recommendations, authoritative certifications, and trusted testing results, underscores their importance across various domains. As technology continues to evolve, integrating intelligence into sealing solutions could usher in a new era of smart and sustainable living. Whether for energy efficiency, enhanced durability, or aesthetic appeal, knowledgeable application and diligent maintenance of seal strips ensure they remain an invaluable asset in modernization efforts.

Innovative trends further enhance the value proposition for seal strips. The advent of smart seal strips that offer IoT integrations to monitor efficiency can shift paradigms. Imagine a home where seal strips provide data analytics on energy savings or signal when replacement is due. This synergy of technology and traditional products could redefine user interaction and engagement with everyday items. Enhancing a seal strip's efficacy also dwells heavily on proper installation practices. Professional installers stress the significance of cleaning the surface prior to installation to ensure adhesive bonding is optimal. Neglecting this step could lead to premature failure or diminished sealing capability. Users are advised to follow manufacturer instructions rigorously or employ professional services to guarantee the installation is executed flawlessly. Finally, the maintenance of seal strips is equally critical to prolong their effectiveness. Routine inspections to check for wear and tear, especially in high-traffic areas or harsh environments, can preemptively address potential failures. Simple actions such as seasonal cleanings or reapplication of adhesive can significantly extend the product lifecycle. In conclusion, seal strips offer substantial benefits when chosen and used correctly. This comprehensive understanding of seal strips, integrating personal experiences, expert material selection recommendations, authoritative certifications, and trusted testing results, underscores their importance across various domains. As technology continues to evolve, integrating intelligence into sealing solutions could usher in a new era of smart and sustainable living. Whether for energy efficiency, enhanced durability, or aesthetic appeal, knowledgeable application and diligent maintenance of seal strips ensure they remain an invaluable asset in modernization efforts.

Latest news

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025