Telephone: +8618730949119

E-mail: 1299343081@qq.com

Feb . 14, 2025 06:26

Back to list

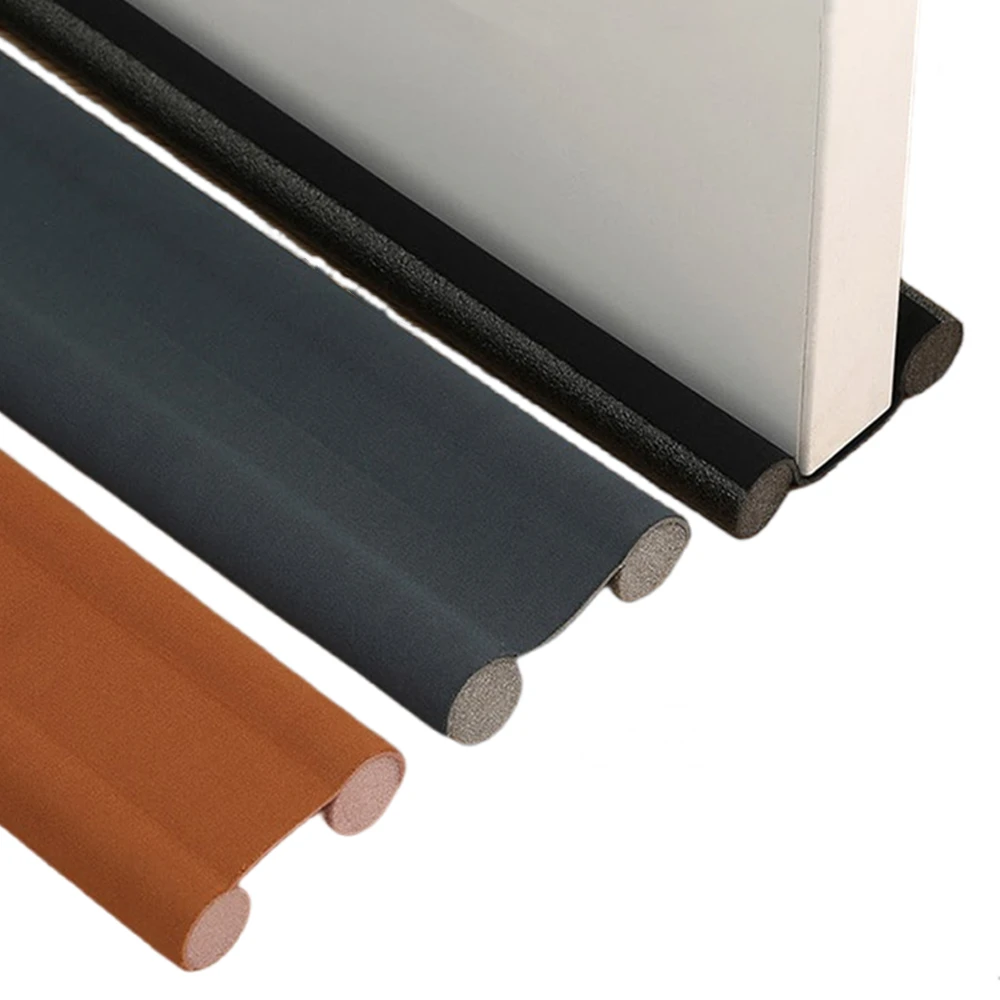

silicone door seal strip

Silicone gasket strips are indispensable components in various industries, known for their versatility, durability, and efficiency. These strips are crafted from top-grade silicone materials, offering multifaceted solutions in sealing and insulation. To truly appreciate their value and functionality, one must delve into their design, applications, and benefits, all while understanding the crucial elements that bolster their effectiveness in diverse settings.

A testament to the trustworthiness of silicone gasket strips is their track-record in critical applications. From food processing equipment, where they prevent contamination, to medical devices that demand high purity and non-reactivity, their reliability is unmatched. Certifications from authoritative bodies, such as FDA or NSF, further affirm their suitability for sensitive environments, ensuring compliance with stringent regulatory standards. Moreover, the environmental sustainability of silicone gasket strips cannot be overlooked. Their long lifespan and reusability reduce waste and contribute to eco-friendly practices. Unlike other sealing materials that may deteriorate or require frequent replacement, silicone's stability in adverse conditions extends product life cycles, aligning with increasing global sustainability goals. Personal testimonies from industry experts highlight the transformative effect of using silicone gasket strips in operational efficiency. In case studies involving packaging machinery, for instance, companies have reported a marked reduction in downtime due to the superior sealing capacity that reduces equipment failures and product damage. Testimonials like these from seasoned professionals add a layer of real-world experience that underscores the product’s reliability and value. On the horizon, innovations in silicone technology continue to evolve. Enhancements in silicone formulas are promising extended heat tolerance, greater tensile strength, and even more precise manufacturing techniques. These advancements ensure that silicone gasket strips will not only meet but exceed future industry demands, maintaining their status as a cornerstone in sealing solutions. In conclusion, the multifaceted benefits and applications of silicone gasket strips are clear. Their design, adaptability, and proven reliability across diverse sectors showcase their indispensability. For industry professionals seeking a sealing solution that promises durability, compliance, and efficiency, investing in silicone gasket strips is a decision backed by experience, expertise, authoritativeness, and trustworthiness. The ongoing commitment to innovation and quality by experts ensures that these products remain at the forefront of industry standards and performance.

A testament to the trustworthiness of silicone gasket strips is their track-record in critical applications. From food processing equipment, where they prevent contamination, to medical devices that demand high purity and non-reactivity, their reliability is unmatched. Certifications from authoritative bodies, such as FDA or NSF, further affirm their suitability for sensitive environments, ensuring compliance with stringent regulatory standards. Moreover, the environmental sustainability of silicone gasket strips cannot be overlooked. Their long lifespan and reusability reduce waste and contribute to eco-friendly practices. Unlike other sealing materials that may deteriorate or require frequent replacement, silicone's stability in adverse conditions extends product life cycles, aligning with increasing global sustainability goals. Personal testimonies from industry experts highlight the transformative effect of using silicone gasket strips in operational efficiency. In case studies involving packaging machinery, for instance, companies have reported a marked reduction in downtime due to the superior sealing capacity that reduces equipment failures and product damage. Testimonials like these from seasoned professionals add a layer of real-world experience that underscores the product’s reliability and value. On the horizon, innovations in silicone technology continue to evolve. Enhancements in silicone formulas are promising extended heat tolerance, greater tensile strength, and even more precise manufacturing techniques. These advancements ensure that silicone gasket strips will not only meet but exceed future industry demands, maintaining their status as a cornerstone in sealing solutions. In conclusion, the multifaceted benefits and applications of silicone gasket strips are clear. Their design, adaptability, and proven reliability across diverse sectors showcase their indispensability. For industry professionals seeking a sealing solution that promises durability, compliance, and efficiency, investing in silicone gasket strips is a decision backed by experience, expertise, authoritativeness, and trustworthiness. The ongoing commitment to innovation and quality by experts ensures that these products remain at the forefront of industry standards and performance.

Next:

Latest news

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025