Telephone: +8618730949119

E-mail: 1299343081@qq.com

Feb . 15, 2025 07:46

Back to list

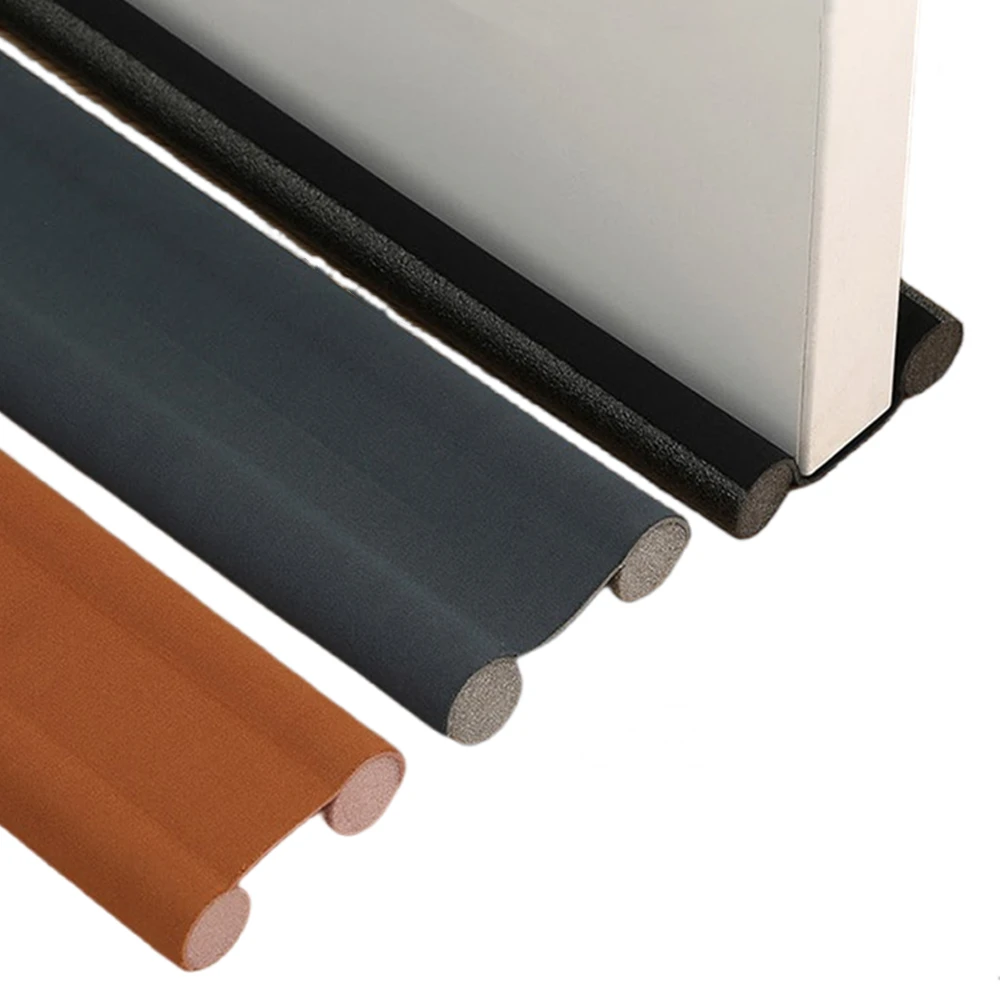

Gap Solid Silicone Rubber Strip Anti Oil High Temp

The silicone weatherstrip seal stands as a significant yet oft-overlooked component in the comprehensive realm of home improvement and automotive maintenance. With its unique combination of flexibility and solidity, it addresses a multitude of consumer needs, offering an unobtrusive yet essential service by ensuring airtight seals in a variety of applications.

The versatility of silicone weatherstrip seals enables their application across various domains, including industrial machinery, wherein they function as pivotal components in ensuring operational efficacy and safety. The seals' remarkable resistance to chemical degradation makes them suitable for use in environments exposed to oils, solvents, or acids, often outperforming other materials that wear quickly under similar conditions. Industry experts recognize this feature as essential for maintaining the integrity and performance of complex machinery. Regarding installation, silicone weatherstrip seals exhibit remarkable user-friendliness. The material's flexibility allows for seamless application across irregular surfaces without compromising the seal's integrity. This adaptability is crucial for DIY enthusiasts and professionals alike, reducing the complexity and time associated with installation. Manuals often highlight silicone's ability to conform to different shapes and sizes, underlying its practicality for an array of projects from household upgrades to specialized industrial applications. In conclusion, the silicone weatherstrip seal embodies a synthesis of practicality and excellence, reflecting high performance in diverse scenarios. Its contributions to energy conservation, noise reduction, and durability not only enhance quality of life but also align with broader environmental goals and economic considerations. Professionals within the field attest to its reliability—whether applied in residential settings or incorporated into sophisticated automotive and industrial systems. As such, choosing silicone weatherstrip seals reflects an informed decision toward investing in a sustainable, efficient, and cost-effective solution.

The versatility of silicone weatherstrip seals enables their application across various domains, including industrial machinery, wherein they function as pivotal components in ensuring operational efficacy and safety. The seals' remarkable resistance to chemical degradation makes them suitable for use in environments exposed to oils, solvents, or acids, often outperforming other materials that wear quickly under similar conditions. Industry experts recognize this feature as essential for maintaining the integrity and performance of complex machinery. Regarding installation, silicone weatherstrip seals exhibit remarkable user-friendliness. The material's flexibility allows for seamless application across irregular surfaces without compromising the seal's integrity. This adaptability is crucial for DIY enthusiasts and professionals alike, reducing the complexity and time associated with installation. Manuals often highlight silicone's ability to conform to different shapes and sizes, underlying its practicality for an array of projects from household upgrades to specialized industrial applications. In conclusion, the silicone weatherstrip seal embodies a synthesis of practicality and excellence, reflecting high performance in diverse scenarios. Its contributions to energy conservation, noise reduction, and durability not only enhance quality of life but also align with broader environmental goals and economic considerations. Professionals within the field attest to its reliability—whether applied in residential settings or incorporated into sophisticated automotive and industrial systems. As such, choosing silicone weatherstrip seals reflects an informed decision toward investing in a sustainable, efficient, and cost-effective solution.

Latest news

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025