Telephone: +8618730949119

E-mail: 1299343081@qq.com

Mar . 07, 2025 05:45

Back to list

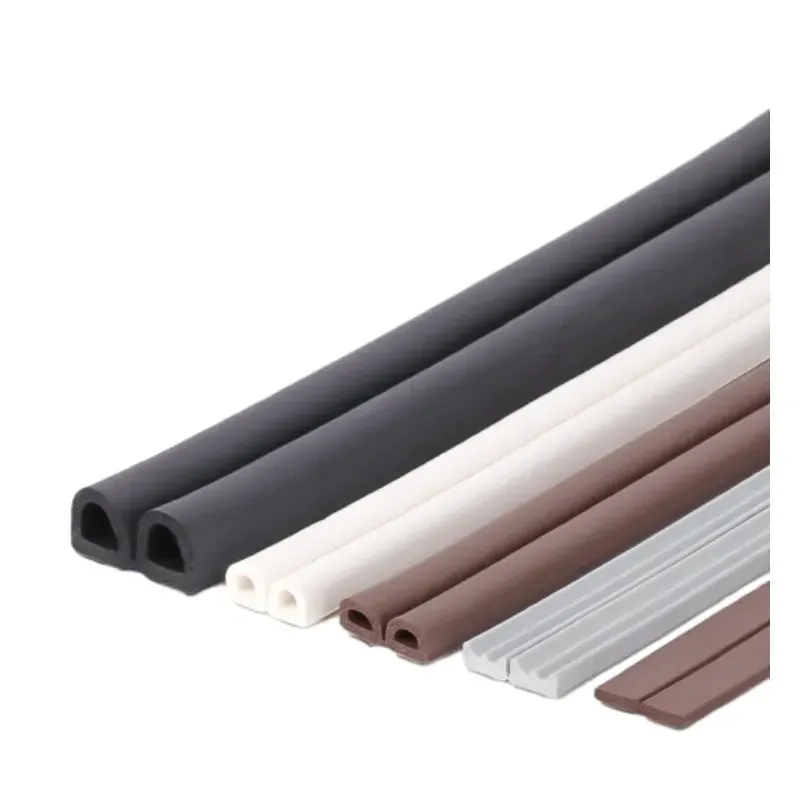

Gap Solid Silicone Rubber Strip Anti Oil High Temp

Solid rubber strips are often underappreciated components in industries spanning from automotive to construction. Yet, these versatile pieces of rubber are pivotal for numerous applications, providing essential benefits that enhance operational efficiency and product longevity.

The authoritativeness of solid rubber strips is well-documented through numerous case studies and industry reports, which highlight their integral role in enhancing product durability and safety. For example, in the construction industry, these strips are frequently used as dampeners or noise reducers, contributing to more comfortable and safer building environments. This positions them as authoritative solutions endorsed by engineers and architects alike for improving both the structural integrity and the livability of buildings. Trustworthiness is, of course, a cornerstone of any component used in critical applications. Solid rubber strips, accredited by industry certifications and quality standards such as ISO 9001, assure engineers and end-users of their performance and reliability. Additionally, their extensive field use, coupled with positive customer testimonials, offers a body of evidence that reinforces their credibility and dependability. In conclusion, solid rubber strips may appear to be simple components, but their application is sophisticated and multi-faceted. Understanding their benefits and characteristics is crucial for anyone involved in industries that require precise sealing and protection solutions. By selecting the right rubber material and manufacturing processes, businesses can significantly enhance the performance and longevity of their products. These strips are not just accessory parts but are instrumental in maintaining product efficiency and operational integrity, reflecting true value in practical, reliable solutions.

The authoritativeness of solid rubber strips is well-documented through numerous case studies and industry reports, which highlight their integral role in enhancing product durability and safety. For example, in the construction industry, these strips are frequently used as dampeners or noise reducers, contributing to more comfortable and safer building environments. This positions them as authoritative solutions endorsed by engineers and architects alike for improving both the structural integrity and the livability of buildings. Trustworthiness is, of course, a cornerstone of any component used in critical applications. Solid rubber strips, accredited by industry certifications and quality standards such as ISO 9001, assure engineers and end-users of their performance and reliability. Additionally, their extensive field use, coupled with positive customer testimonials, offers a body of evidence that reinforces their credibility and dependability. In conclusion, solid rubber strips may appear to be simple components, but their application is sophisticated and multi-faceted. Understanding their benefits and characteristics is crucial for anyone involved in industries that require precise sealing and protection solutions. By selecting the right rubber material and manufacturing processes, businesses can significantly enhance the performance and longevity of their products. These strips are not just accessory parts but are instrumental in maintaining product efficiency and operational integrity, reflecting true value in practical, reliable solutions.

Latest news

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025