t rubber strip

Understanding the Versatility of Rubber Strips A Comprehensive Guide

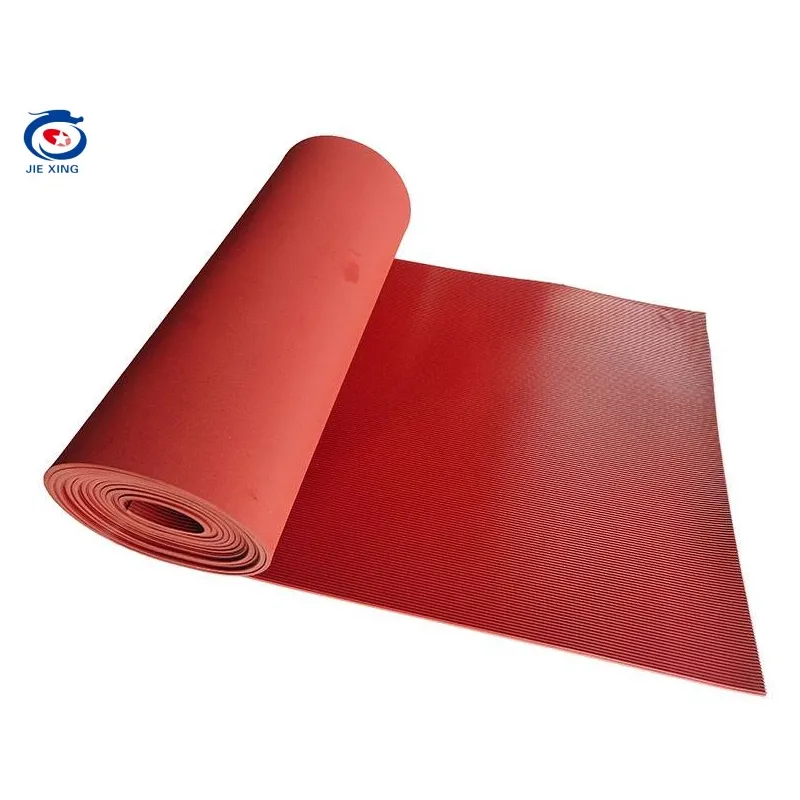

Rubber strips are a remarkably versatile material that find applications in a wide range of industries and everyday uses. Made from natural or synthetic rubber, these strips come in various shapes, sizes, and hardness, making them suitable for numerous applications. This article explores the characteristics, uses, and benefits of rubber strips, highlighting their importance in both industrial and domestic contexts.

Characteristics of Rubber Strips

Rubber strips are known for their excellent flexibility and durability. Their elastic nature allows them to stretch and compress without losing their original shape, making them ideal for various sealing and cushioning applications. Rubber strips can also withstand a wide range of temperatures, which is crucial for environments where thermal expansion and contraction are common. Additionally, they exhibit resistance to chemicals, oils, and UV light, further enhancing their longevity and making them suitable for outdoor and industrial environments.

The thickness and width of rubber strips can vary significantly, allowing for customization based on specific needs. Whether a project requires a thin, flexible strip for sealing or a thicker, more robust variant for heavy-duty use, the rubber industry offers a myriad of options. Moreover, rubber strips can be manufactured in different colors and finishes, enabling aesthetic considerations to be integrated into functional designs.

Applications of Rubber Strips

The applications of rubber strips are vast and varied. In the construction industry, they are frequently used as weather seals for doors and windows, helping to maintain indoor temperatures and reduce energy costs. The automotive sector also relies on rubber strips for door seals, window trims, and other components that require a reliable barrier against water and air.

t rubber strip

In manufacturing, rubber strips serve as vibration dampeners, helping to minimize noise and wear on machinery. This function is critical in industries where heavy machinery operates, as excessive vibration can lead to reduced equipment lifespan and increased maintenance costs. Additionally, rubber strips are commonly utilized in packaging, providing cushioning for fragile items during transport.

In the realm of home improvement, rubber strips are often found in DIY projects. Homeowners use them for various applications, such as creating non-slip surfaces, adding protective barriers in bathrooms, or even crafting custom mats for garages. The versatility of rubber strips makes them a go-to choice for both professionals and DIY enthusiasts alike.

Benefits of Using Rubber Strips

One of the primary benefits of rubber strips is their cost-effectiveness. Compared to other materials, rubber provides a reliable solution that is often more affordable without sacrificing quality. Furthermore, their long lifespan and resistance to wear make them a practical choice for many applications, leading to reduced replacement costs over time.

Additionally, the ease of installation associated with rubber strips cannot be overlooked. Many of them come with adhesive backing or can be cut to size, allowing for quick and hassle-free application. This feature is particularly advantageous for individuals looking to perform home repairs or improvements without requiring professional help.

Conclusion

Rubber strips are an indispensable material that serves countless purposes across various sectors. Their unique properties, such as flexibility, durability, and resistance to environmental factors, make them ideal for numerous applications. Whether used in industrial settings, automotive designs, or DIY home projects, rubber strips offer a practical and cost-effective solution for sealing, cushioning, and protecting. As innovation continues to progress, it is likely that new applications for rubber strips will emerge, further cementing their role as a vital component in both industry and everyday life.

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025