v shaped rubber seal

The Benefits and Applications of V-Shaped Rubber Seals

In various industries, the integrity of a product often hinges on the quality of its seals. Among the myriad of sealing solutions available, the V-shaped rubber seal stands out for its unique design and versatile applications. This innovative sealing solution is gaining traction due to its remarkable features that address diverse sealing needs, from automotive to industrial applications.

The Benefits and Applications of V-Shaped Rubber Seals

One of the primary benefits of V-shaped rubber seals is their application in dynamic sealing environments. These seals are commonly used in machinery with moving parts, where traditional flat seals might fail to maintain their integrity over time. The V shape allows for a more robust engagement with the surfaces being sealed, reducing the risk of wear and tear. This adaptability translates into longer service life and reduced maintenance costs, which are critical factors in manufacturing and production settings.

v shaped rubber seal

In the automotive sector, V-shaped rubber seals are widely used in various applications, including doors, windows, and engine components. Their ability to provide excellent acoustic and thermal insulation is particularly valuable in this context, contributing to a quieter and more comfortable ride. Furthermore, these seals effectively prevent the ingress of dust, water, and other contaminants, which is vital for maintaining the longevity of automotive components.

The versatility of V-shaped rubber seals extends beyond the automotive field. In the food and beverage industry, they play a crucial role in ensuring hygiene and safety. These seals are used in processing equipment, packaging machinery, and even in creating airtight containers. Their resistance to a range of chemicals and temperatures helps preserve the integrity of the products being manufactured and stored.

Moreover, V-shaped rubber seals can be tailored to meet specific requirements. Available in various sizes, materials, and durometers, manufacturers can customize these seals to suit their precise needs. This level of customization enhances the performance of the seal, ensuring that it can withstand environmental factors such as UV exposure, extreme temperatures, or chemical contact.

In conclusion, V-shaped rubber seals represent a critical element in the design and functionality of modern products across various industries. Their unique shape, flexibility, and resistance to wear make them a preferred choice for many applications, while their customizable nature ensures that specific needs can be addressed effectively. As industries continue to evolve, the demand for reliable sealing solutions like the V-shaped rubber seal is likely to grow, highlighting its importance in maintaining product integrity and performance. Using these advanced seals can lead to enhanced efficiency, reduced costs, and improved overall outcomes across a multitude of sectors.

-

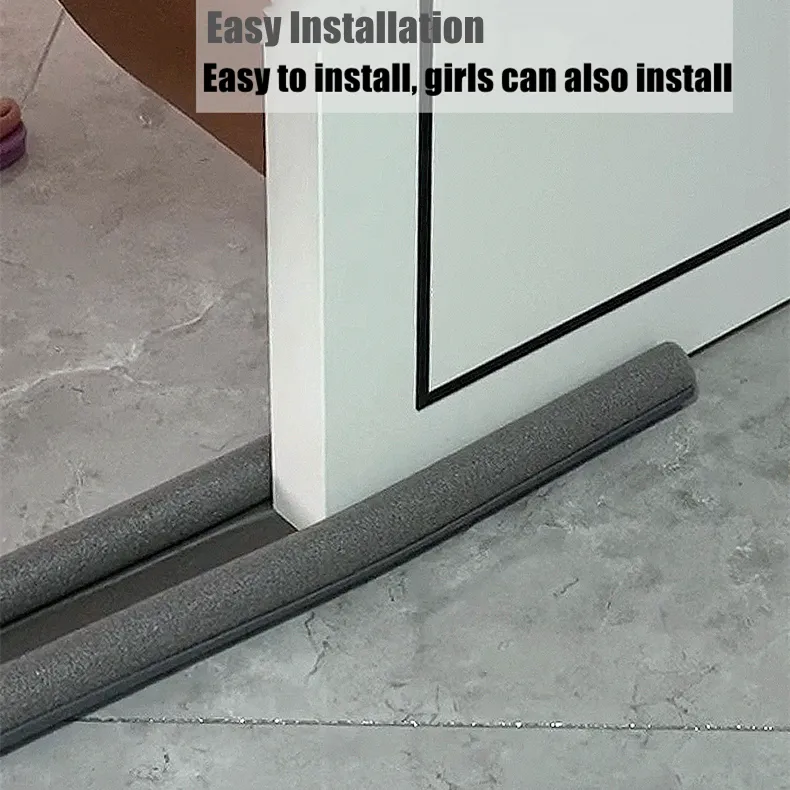

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025