Exploring the Benefits of White Iron in Edge Banding Applications

White Iron on Edge Banding An Overview

Edge banding is an essential process in the woodworking and furniture industry, vital for enhancing the aesthetic quality and durability of finished products. Among the various materials used in edge banding, white iron has emerged as a noteworthy option due to its unique characteristics and benefits. This article explores the significance of white iron in edge banding, the advantages it presents, and its applications in modern furniture design.

What is Edge Banding?

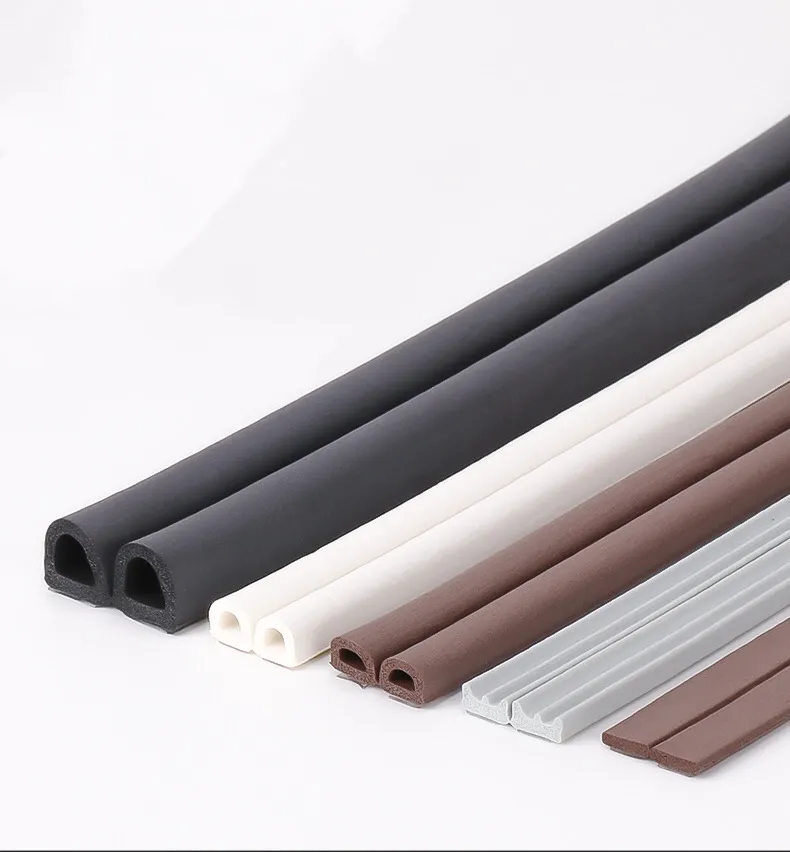

Edge banding refers to the process of covering the exposed edges of particleboard, plywood, or MDF (medium-density fiberboard) with a thin strip of material. This not only improves the appearance of the furniture but also protects the edges from moisture, damage, and wear. Traditionally, edge banding materials include plastic, wood veneer, and laminates, each with their own pros and cons. However, the introduction of white iron as an edge banding material brings forth new possibilities.

What is White Iron?

White iron is a form of cast iron characterized by its high carbon content and the presence of cementite, which gives it a hard and brittle structure. Its notable hardness makes it an excellent choice for producing wear-resistant surfaces. White iron is typically used in applications requiring robust materials capable of withstanding high stress and wear. However, its use in edge banding is innovative and represents a shift in how we design and think about furniture components.

Advantages of White Iron in Edge Banding

1. Durability One of the primary reasons for using white iron in edge banding is its exceptional durability. The hard surface is resistant to scratches, dents, and abrasions, making it ideal for furniture that experiences heavy use, such as kitchen cabinets and office desks.

2. Aesthetics White iron can provide a sleek, modern look that complements contemporary design trends. Its metallic finish can enhance the overall appeal of the product, offering a striking contrast to traditional wood finishes.

white iron on edge banding

3. Moisture Resistance Unlike traditional wood banding, which can swell or warp when exposed to moisture, white iron is impervious to water. This property is particularly advantageous in environments with high humidity, ensuring longevity and maintaining the structural integrity of the furniture.

4. Easy Maintenance The smooth surface of white iron edge banding makes it easy to clean and maintain. Regular dusting or wiping with a damp cloth is usually sufficient to keep it looking new, allowing for a hassle-free ownership experience.

5. Sustainability As manufacturers seek eco-friendly solutions, the use of recycled metals for edge banding is gaining traction. White iron can be produced sustainably, offering a greener alternative to plastic or synthetic materials.

Applications in Modern Furniture Design

Incorporating white iron into edge banding can open up various design possibilities. Furniture designers are taking advantage of its unique properties to create innovative pieces that are not only functional but also visually striking. From industrial-style tables featuring raw metal edges to modern cabinetry with sleek finishes, white iron is proving to be a versatile material in contemporary design.

Furthermore, its applications extend beyond residential furniture. In commercial settings, such as offices and retail spaces, the durability and stylish appearance of white iron edge banding can elevate the overall environment, providing a sophisticated yet robust solution.

Conclusion

White iron in edge banding represents an exciting development in woodworking and furniture design. Combining durability, aesthetic appeal, and sustainability, it is poised to become a popular choice among manufacturers and consumers alike. As the furniture industry continues to evolve, white iron is set to play an integral role in shaping the future of edge banding, enhancing functionality and style in modern design.

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025