Telephone: +8618730949119

E-mail: 1299343081@qq.com

Feb . 15, 2025 23:01

Back to list

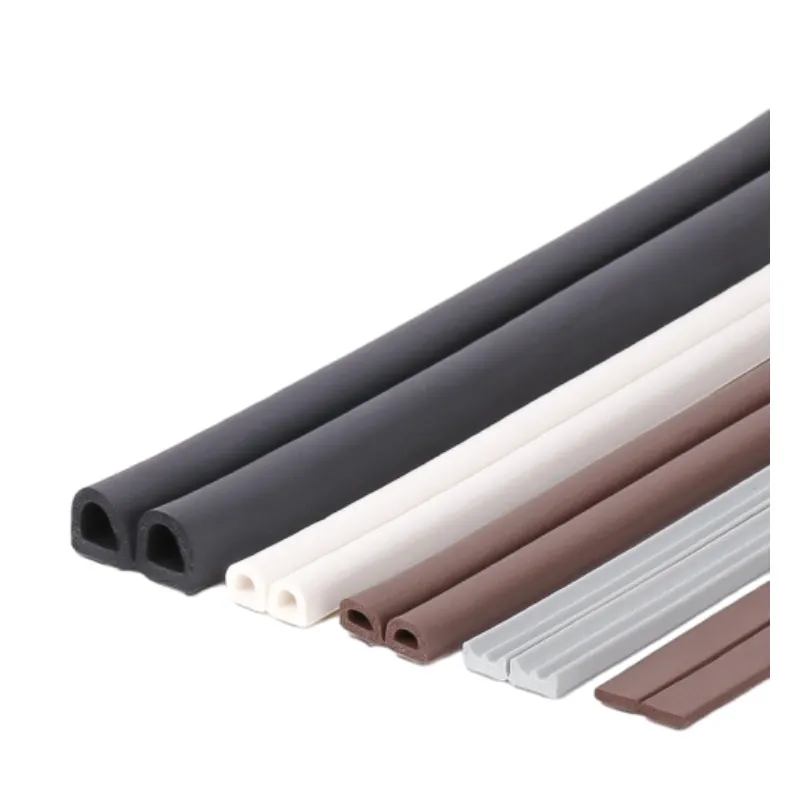

edge banding tape

White iron-on edge banding can transform any project from looking amateurish to exhibiting a professional, polished finish. As someone deeply entrenched in the industry, it's clear how essential edge banding is for enhancing both aesthetics and durability in various applications, including cabinetry, furniture, and interior design.

Furthermore, the authoritative nature of white iron-on edge banding is reflected in its widespread professional use. It is a staple in both residential and commercial projects, renowned for its durability and aesthetic appeal. Its strength lies in both its physical and visual properties—durable enough to withstand the rigors of constant use while maintaining a fresh appearance that adds value to any space it adorns. When considering its credibility, the eco-friendly manufacturing process of quality white edge banding is increasingly aligning with sustainable construction practices. Many manufacturers have adopted low-emission processes, ensuring that while the edge banding enhances your space, it also supports environmental well-being. Trust, as a cornerstone of this product, is further reinforced by its track record. Numerous case studies demonstrate its successful application in various industries, portraying it as a reliable choice. This history nurtures a trust that professionals and consumers can bank on, knowing that their investment in quality edge banding will prove beneficial in the long run. In summary, white iron-on edge banding embodies more than just a finishing touch—it is a strategic component in modern design. Its combination of adaptability, ease of application, durability, and environmental consciousness makes it an invaluable asset in professional and residential settings alike. Embracing this product's full potential involves recognizing its inherent ability to elevate the ordinary to extraordinary, which is testament to its seamless integration of form and function.

Furthermore, the authoritative nature of white iron-on edge banding is reflected in its widespread professional use. It is a staple in both residential and commercial projects, renowned for its durability and aesthetic appeal. Its strength lies in both its physical and visual properties—durable enough to withstand the rigors of constant use while maintaining a fresh appearance that adds value to any space it adorns. When considering its credibility, the eco-friendly manufacturing process of quality white edge banding is increasingly aligning with sustainable construction practices. Many manufacturers have adopted low-emission processes, ensuring that while the edge banding enhances your space, it also supports environmental well-being. Trust, as a cornerstone of this product, is further reinforced by its track record. Numerous case studies demonstrate its successful application in various industries, portraying it as a reliable choice. This history nurtures a trust that professionals and consumers can bank on, knowing that their investment in quality edge banding will prove beneficial in the long run. In summary, white iron-on edge banding embodies more than just a finishing touch—it is a strategic component in modern design. Its combination of adaptability, ease of application, durability, and environmental consciousness makes it an invaluable asset in professional and residential settings alike. Embracing this product's full potential involves recognizing its inherent ability to elevate the ordinary to extraordinary, which is testament to its seamless integration of form and function.

Next:

Latest news

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025