Choosing the Right Wood Edge Banding Tape for Your Projects

The Importance of Wood Edge Banding Tape in Furniture Manufacturing

Wood edge banding tape is a vital component in the furniture manufacturing industry. It serves both practical and aesthetic purposes, ultimately enhancing the quality and appearance of wood products. Understanding the significance and uses of edge banding tape can help manufacturers and hobbyists alike make informed decisions in their projects.

What is Wood Edge Banding Tape?

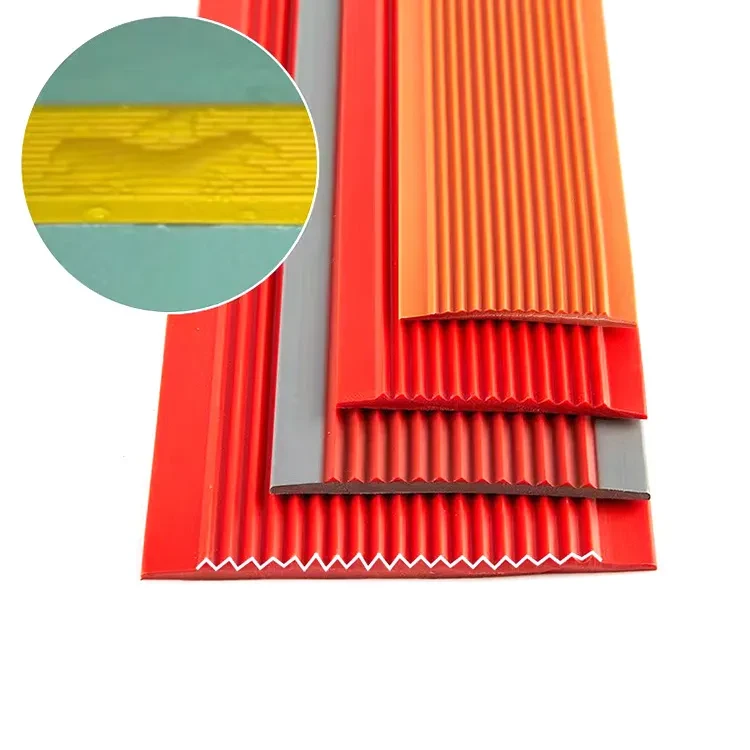

Wood edge banding tape is a narrow strip of material applied to the exposed edges of wood panels. It is typically made from a variety of materials, including PVC, melamine, paper, and real wood veneer. The primary function of edge banding is to cover the raw edges of plywood, MDF, or particleboard, which not only improves their appearance but also protects the material from moisture and damage.

Aesthetic Benefits

One of the most immediate benefits of using edge banding tape is its ability to enhance the visual appeal of wooden furniture. Many people prefer the look of solid wood over manufactured products; edge banding helps to imitate that appearance by providing a seamless finish. The tape comes in various colors, textures, and finishes, allowing manufacturers to match the edge banding perfectly with the wood grain or finish of the main panel. This ability to blend or contrast the edges with the surface material provides designers with great flexibility in their creations.

Functional Advantages

Beyond aesthetics, wood edge banding tape offers several functional advantages. One of the most significant benefits is its role in protecting the edges of the wood from moisture, dirt, and wear. Exposed edges are prone to absorb water, leading to swelling and deformation. By adhering a strip of edge banding, the integrity of the wood is preserved, prolonging the lifespan of the furniture.

Moreover, edge banding provides a smooth surface that eliminates sharp edges, making furniture safer, especially in homes with children. A well-applied edge banding can also resist chipping and peeling, ensuring that the furniture maintains its sleek appearance throughout its use.

wood edge banding tape

Application Techniques

The process of applying edge banding tape has significantly evolved, thanks to advancements in technology. While hand application is still common in some smaller workshops, many manufacturers now utilize specialized machines that offer precision and efficiency. These machines can apply heat to melt the adhesive on the tape, ensuring a strong bond with the wood surface.

For DIY enthusiasts, there are simpler methods available. Double-sided adhesive tapes or hot glue guns can effectively bond edge banding, although achieving a professional finish may require some practice.

Choosing the Right Edge Banding

Selecting the appropriate edge banding tape depends on the specific application and desired finish. For example, PVC edge banding is popular in high-traffic areas due to its durability and resistance to moisture. Conversely, real wood veneer might be preferred for high-end furniture pieces where aesthetic appeal is paramount.

Another consideration is the thickness of the edge banding. Thicker tapes can provide greater protection and a more substantial visual effect, while thinner options offer a more delicate appearance.

Conclusion

In summary, wood edge banding tape is an essential tool in the furniture manufacturing process. Its ability to improve the aesthetics and functionality of wooden products cannot be understated. Whether you are a professional manufacturer or a DIY enthusiast, understanding the benefits and proper application techniques of edge banding tape will enhance your woodworking projects. Investing in quality edge banding not only increases the visual appeal of your work but also ensures longevity and durability, ultimately leading to satisfied customers and successful creations.

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025