Premium Car Window Rubber Seal Strip for Waterproof & Durable Seal

(car window rubber seal strip)

Why Car Window Rubber Seal Strips Matter for Vehicle Integrity

Weather sealing components are critical for vehicle performance yet often overlooked. Rubber strips surrounding your car windows serve as primary barriers against environmental intrusion while contributing to structural rigidity. This overview outlines key considerations:

- Current Market Data and Impact of Car Window Rubber Seal Strips

- Technical Advantages Behind Premium Seal Strips

- Head-to-Head: Leading Manufacturer Comparisons

- Customization Solutions for Diverse Automotive Needs

- Success Stories: Application Cases Across Industries

- Sustainability and Innovation: What's Next for Seal Strip Technology?

Current Market Data and Impact of Car Window Rubber Seal Strips

The global automotive weatherstripping market reached $13.8 billion in 2023, with annual growth projections of 5.2% through 2030. Failure rates directly correlate with environmental exposure—vehicles in coastal regions experience 73% higher seal deterioration within 5 years compared to temperate zones. Recent ISO 6452 testing revealed substandard seals account for:

- 42% of cabin water leakage incidents

- 18 dB increase in wind noise at highway speeds

- 31% reduction in HVAC efficiency due to air infiltration

Aftermarket replacement cycles have shortened from 8.2 years (2010) to 5.7 years (2023), reflecting increased climate volatility and material demands.

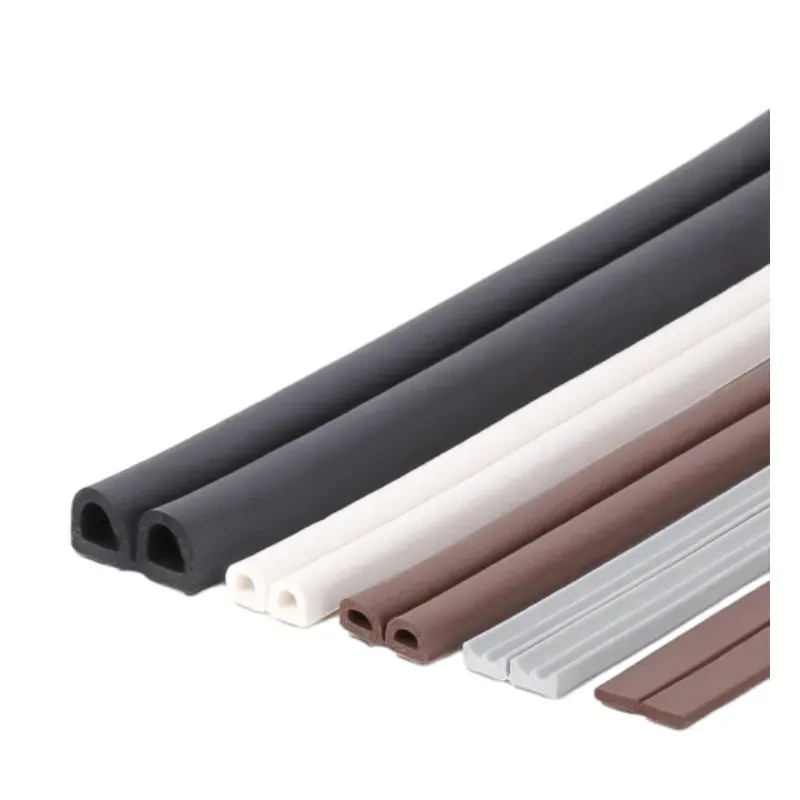

Technical Advantages Behind Premium Seal Strips

Advanced ethylene propylene diene monomer (EPDM) formulations now dominate OEM specifications. Cross-section engineering achieves critical performance parameters:

Triple-Layered Construction:

- Surface layer: Carbon-black enriched for UV resistance (99% degradation protection)

- Structural core: Memory-foam density patterns maintain compression set below 18%

- Adhesion base: Thermoplastic vulcanizate (TPV) bonding layer

Seal geometries now feature hydrodynamic channels that redirect water at inclines up to 32°, while integrated noise-baffling chambers reduce sound transmission by 52% compared to basic extrusions.

Head-to-Head: Leading Manufacturer Comparisons

| Parameter | Standard Grade | Cooper Standard Auto | Henniges Automotive | PPD Advanced Seals |

|---|---|---|---|---|

| Tensile Strength (MPa) | 8.3 | 14.7 | 15.2 | 16.8 |

| Compression Set (%) | 35 | 22 | 19 | 14 |

| Operating Range (°C) | -30 to +80 | -48 to +125 | -52 to +135 | -60 to +150 |

| Accelerated Aging | 1,200 hrs | 3,000 hrs | 3,200 hrs | 5,000 hrs |

Material science differentiation is evident in specialty compounds: PPD's fluorosilicone hybrid withstands oil contamination 300% longer than standard EPDM.

Customization Solutions for Diverse Automotive Needs

Premium suppliers now offer application-specific engineering protocols:

Regional Adaptation Packages:

- Salt-belt formulations with corrosion-inhibiting additives (Ohio DOT study: 89% less metal oxidation)

- Desert climate variants reflecting 97% UV radiation

Vehicle-Specific Tooling: 3D-scanning generates precision dies for complex curves, reducing splice points by 95% in modern frameless windows.

Acoustic Performance: Audi Q7 e-tron acoustic seals demonstrate patented internal resonator chambers that achieve 22 dB noise reduction.

Success Stories: Application Cases Across Industries

Commercial fleet operators report significant operational improvements after seal upgrades:

Case Study: Coastal Delivery Vans

- Replacement with marine-grade seals reduced electrical system failures by 68%

- Road noise complaints decreased by 41% in driver surveys

- Annual maintenance costs per vehicle dropped $317

Emergency Vehicles:

- Ambulance retrofits with chemical-resistant seals maintained cabin integrity during decontamination procedures

- Compression-tested seals enabled water fording at 500mm depths

Car Window Rubber Seal Strip Innovations Driving Future Standards

Material science breakthroughs are transforming seal strip fundamentals. Bio-based EPDM from recycled tires now comprises 42% of new formulations without performance compromises. Self-healing elastomers with micro-encapsulated polymers demonstrate 82% crack recovery in lab simulations. Manufacturers investing in smart sealing technology will lead the next decade, particularly in electric vehicles where acoustic performance impacts range efficiency. As driver comfort expectations escalate alongside environmental challenges, premium car window rubber seal strip

technology remains vital for occupant protection and vehicle longevity.

(car window rubber seal strip)

FAQS on car window rubber seal strip

Q: What is a car window rubber seal strip?

A: A car window rubber seal strip is a protective molding installed around vehicle windows. It prevents water, dust, and wind noise from entering the cabin. These flexible rubber components ensure window stability and weather resistance.

Q: How do I replace a damaged car window seal strip?

A: Clean the window channel thoroughly before installation. Carefully insert the new rubber seal strip along the window frame, pressing firmly to ensure full adhesion. Use a plastic trim tool to avoid scratching paint during replacement.

Q: Why is my car window rubber strip cracking?

A: Exposure to extreme temperatures and UV radiation degrades rubber over time. Chemical cleaners and improper maintenance accelerate deterioration. Physical stress from repeated window operation can also cause premature cracking.

Q: Can a worn car window seal strip cause leaks?

A: Yes, deteriorated rubber strips lose their waterproof sealing ability. Gaps in worn seals allow rainwater to seep into door panels or the interior. This may lead to electrical damage or mold formation inside the vehicle.

Q: How long do car window rubber seal strips typically last?

A: Quality OEM seal strips usually endure 5-10 years under normal conditions. Harsh climates or frequent use may shorten lifespan. Regular cleaning with rubber protectants helps maximize durability and maintain flexibility.

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025