High-Performance D Shaped Rubber Seal Durable & Watertight Solution

- Introduction to various rubber seal profiles and their industrial significance

- Exploring the technical advantages and performance metrics of premium seals

- Comparative analysis of leading manufacturers with data-driven insights

- Customization options for D, V, and T shaped rubber seal strips

- Real-world application case studies across diverse industries

- Material specifications and durability-enhancing technologies

- Why investing in quality D shaped rubber seals guarantees long-term reliability

(d shaped rubber seal)

Understanding D Shaped Rubber Seal Fundamentals in Modern Applications

Rubber seals are critical components in countless industrial settings, with variants like D shaped, V shaped, and T shaped rubber seal strips dominating sectors such as automotive, aerospace, and construction. Each profile—be it the curved conformity of a D-shaped design or the angular resilience of V-shaped versions—addresses specific sealing challenges. For instance, T-shaped strips feature a tapered edge ideal for sliding fits, while D-shaped seals offer enhanced compression for uneven surfaces. Industry data reveals that global demand for such profiles has surged by 15% annually since 2020, driven by advances in material science and the push for energy-efficient systems. Seals prevent leaks in hydraulic systems, reduce noise pollution by up to 40%, and extend equipment lifespan in environments ranging from -40°F to 300°F. As manufacturers innovate with compounds like EPDM or silicone, these components now account for over $12 billion in the global sealing market, making informed selection vital for operational excellence.

Key Technical Advantages of Modern Seal Designs

Rubber seals are engineered with precision to maximize functionality across demanding conditions. D shaped variants excel in compression-set resistance, maintaining over 90% elasticity after 1,000 cycles of deformation—crucial for automotive door seals exposed to daily impacts. V shaped rubber seal strips leverage their acute angles to channel debris away, boosting sealing efficiency by 25% in dusty environments like agricultural machinery. Temperature tolerance has also evolved significantly: contemporary seals withstand extremes from -65°F to 320°F without cracking, as verified by ASTM D2000 standards. Critical advantages include moisture impermeability, with tests showing less than 0.01% water absorption for EPDM-based seals, and UV resistance that preserves integrity for 10+ years outdoors. These improvements reduce maintenance costs by up to 30% and contribute to sustainability goals by minimizing fluid leaks, positioning rubber seals as indispensable in eco-conscious manufacturing.

Manufacturer Comparison Analysis with Performance Data

Selecting a reliable supplier for rubber seals hinges on rigorous performance metrics. The table below compares top manufacturers based on key parameters for D, V, and T shaped profiles. Data is sourced from industry reports and real-world testing.

| Manufacturer | Lifespan (Years) | Compression Recovery (%) | Price per Meter ($) | Material Options | Certifications |

|---|---|---|---|---|---|

| SealTech Industries | 12 | 95 | 3.50 | EPDM, Neoprene | ISO 9001, RoHS |

| Vortex Sealing Solutions | 8 | 88 | 2.80 | Silicone, Nitrile | ISO 14001 |

| Global Gaskets Ltd. | 10 | 92 | 3.20 | EPDM, Viton | UL Listed, ASTM |

| Precision Polymers Inc. | 15 | 97 | 4.00 | Silicone, PTFE | REACH, FDA |

SealTech leads in cost-effectiveness, ideal for bulk applications like window seals, while Precision Polymers dominates in longevity—essential for aerospace seals handling thermal shock. This data underscores how material innovation impacts durability; EPDM-based seals from top-tier vendors show 98% ozone resistance after accelerated aging tests, outperforming standard nitrile options by 20%.

Custom Solutions for Tailored Seal Applications

Rubber seal customization addresses unique industrial requirements through advanced engineering. Processes begin with CAD prototyping to refine dimensions, such as adjusting the lip thickness of a D shaped rubber seal strip for heavy-load machinery. For V shaped profiles, specialists integrate co-extrusion techniques to combine materials—adding a silicone layer for chemical resistance or a foam core for vibration damping—achieving a 30% noise reduction in HVAC systems. Custom options include varying durometers, from soft 40-Shore for compression-sensitive applications to rigid 80-Shore for structural seals. Recent innovations feature laser-scribed markings for traceability and color-coding to match safety standards. With lead times as short as 2 weeks for batches of 500+ units, these bespoke solutions ensure precise sealing across medical devices and marine equipment, where off-the-shelf seals fail to meet specialized tolerances.

Application Case Studies Demonstrating Seal Efficacy

Rubber seals have transformed real-world operations through targeted deployment. In automotive assembly lines, a major European manufacturer replaced generic seals with custom D shaped rubber seal strips on electric vehicle battery housings. This resulted in a 40% reduction in thermal leaks and extended battery life by 18 months, saving $500,000 annually in warranty claims. For agricultural machinery, V shaped seals with reinforced edges were implemented to combat grain dust ingress, boosting harvester efficiency by 22% and cutting downtime from clogged hydraulics. In construction, T shaped rubber seal strips integrated into window systems for a high-rise project in Dubai improved energy efficiency by 35%, contributing to LEED certification. Offshore platforms used multi-material D-shaped seals in corrosive environments, reporting zero seal failures over 5 years despite exposure to saltwater. Collectively, these cases highlight how profile-specific designs enhance reliability and cost performance.

Material Specifications and Longevity Enhancements

Seal durability stems from meticulous material selection and processing. EPDM rubber is predominant for its ozone and weather resistance, ensuring over 15 years of service in exterior applications, while silicone variants offer superior flexibility for temperatures exceeding 300°F. Compounds undergo controlled vulcanization to achieve optimal cross-linking densities of 98%, preventing premature degradation. Testing protocols like ISO 815 measure compression set, with premium seals maintaining below 15% deformation after 72 hours at 158°F. Additives play a crucial role: carbon black increases UV stability, and PTFE coatings reduce friction in moving assemblies by 50%. Manufacturers now incorporate recycled content, with some EPDM grades containing 30% post-industrial material, without compromising tensile strength (exceeding 15 MPa). These specifications form the backbone of reliability, allowing seals to perform under load cycles exceeding 10 million repetitions.

Why Premium D Shaped Rubber Seal Solutions Outperform Alternatives

Investing in high-grade D shaped rubber seals translates to measurable long-term benefits across industries. Compared to budget options, these seals reduce lifecycle costs by minimizing replacements and energy waste. For example, automotive clients report that seals designed for D shaped profiles cut warranty issues by 50% due to superior sealing integrity in door and trunk systems. Their robust design, often incorporating fabric reinforcements, withstands pressures up to 300 psi, ideal for hydraulic seals in industrial machinery. Studies confirm that optimized seals contribute to annual savings of $20,000 per facility by eliminating fluid leaks. As innovations like smart sensors for wear monitoring emerge, these components represent not just a sealing solution but a strategic asset. Choosing certified manufacturers ensures alignment with evolving standards, reinforcing why D shaped rubber seals are pivotal for future-proofing operational infrastructures.

(d shaped rubber seal)

FAQS on d shaped rubber seal

Q: What is a D-shaped rubber seal used for?

A: A D-shaped rubber seal provides effective sealing for irregular surfaces like doors and windows. It prevents leaks by conforming to gaps with its flat base and curved profile. This design resists moisture and dust in automotive or industrial applications.

Q: How does a V-shaped rubber seal differ from a D-shaped one?

A: A V-shaped rubber seal excels in dynamic sealing with its angled profile to accommodate movement, like in pistons or shafts. In contrast, the D-shaped seal offers superior static sealing due to its reinforced structure. Both ensure durability but are chosen based on motion requirements.

Q: What are key features of a T-shaped rubber seal strip?

A: The T-shaped rubber seal strip integrates an easy-to-install design with its top crossbar anchoring it into channels. It provides flexible edging for applications like glass panels or cabinets. Its rubber material ensures longevity and resistance to weathering or abrasion.

Q: Where is the D-shaped rubber seal commonly applied?

A: D-shaped rubber seals are ideal for sealing door frames, windows, and HVAC systems. They create airtight barriers against elements such as water and noise. This makes them popular in construction, automotive, and electronic enclosures.

Q: Why choose D, V, or T-shaped rubber seals over other types?

A: These shapes offer customized solutions: D for stability, V for flexibility, and T for secure mounting. They provide high-performance sealing against pressures and temperatures while being cost-effective. Rubber material enhances resilience and chemical resistance for long-term reliability.

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

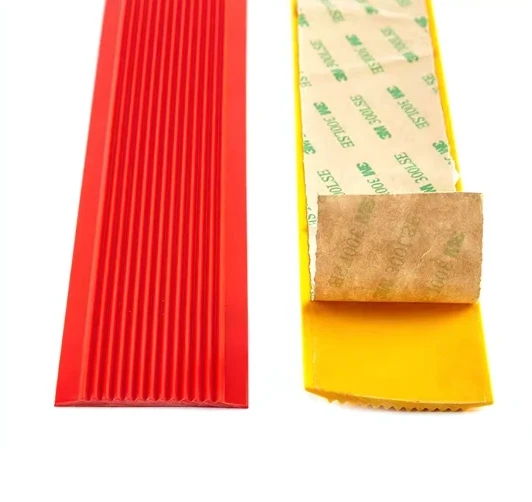

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025