Door Bottom Draught Excluder: Ultimate Draft Stopper & Energy Saver

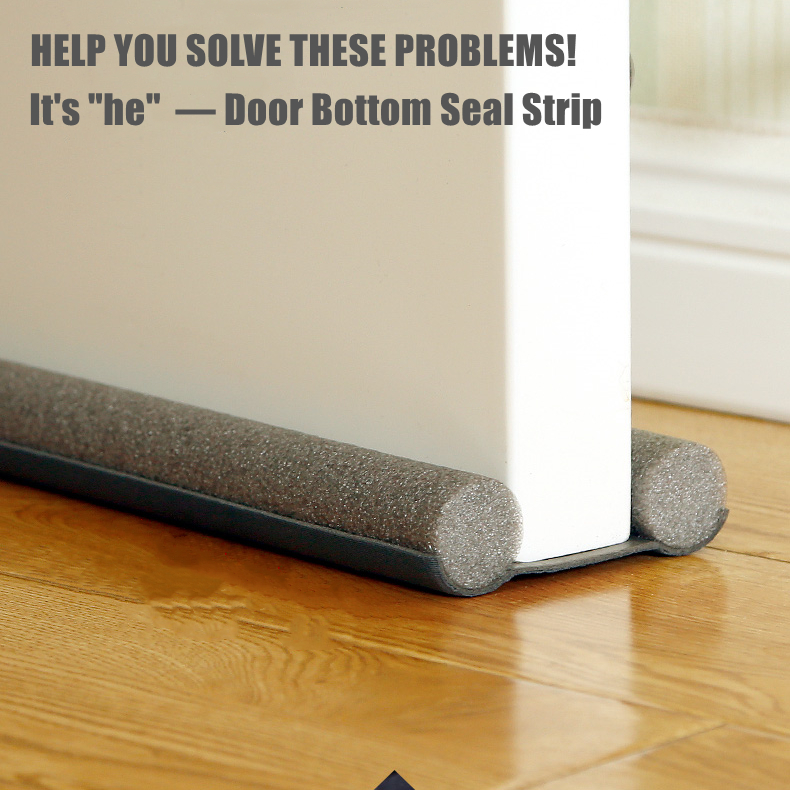

In the modern building and industrial sector, optimizing sealing solutions is crucial for energy efficiency and maintaining indoor environmental quality. The door bottom draught excluder, including variants such as bottom seal door, under door draught stopper, and door bottom seal strip, represent indispensable components across residential, commercial, and industrial domains.

Industry Trend: The Evolving Landscape of Door Sealing Technology

With heightened concern for sustainability and cost-effective energy management, the global door bottom draught excluder market has grown at a steady CAGR of 6.1% (2020-2024). According to Verified Market Research (2023), the segment is expected to reach USD 1.7 billion by 2027. Driving forces include stricter building codes (ASHRAE/ISO 14001), carbon footprint minimization, and customer demand for multi-functional solutions like under door draft stopper and weather-resistant door seals.

- Adoption in smart buildings for optimal HVAC performance

- Trends toward sustainable materials & long-life elastomers (20+ years)

- Growing demand in retrofitting for industrial energy cost control, driven by ANSI/BIFMA and ISO standards

Technical Parameters & Product Overview

The Door bottom sealing strip guard sealer stopper door weatherstrip door seal guard wind dust offers exceptional sealing properties tailored for various environmental demands. Below is a comparison of core parameters with other leading brands:

| Product Name | Material | Sealing Range (mm) | Durability (Cycles) | Installation Type | Certifications |

|---|---|---|---|---|---|

| This Product | Silicone, Aluminum Alloy | 0–25 | >250,000 | Adhesive / Screw | ISO 9001, RoHS |

| Brand X | PVC, Aluminum | 0–18 | >120,000 | Adhesive Only | ISO 9001 |

| Brand Y | EPDM, PVC | 3–20 | >80,000 | Adhesive / Mag. | REACH |

| Brand Z | Thermoplastic | 0–16 | >70,000 | Slide-in | ISO 14001 |

- Superior Silicone Blade: High-resilience, elasticity retention & temperature resistance (-40°C — +150°C)

- Anodized Aluminum Body: Corrosion-resistant, lightweight, and conforms to ANSI/BHMA standards

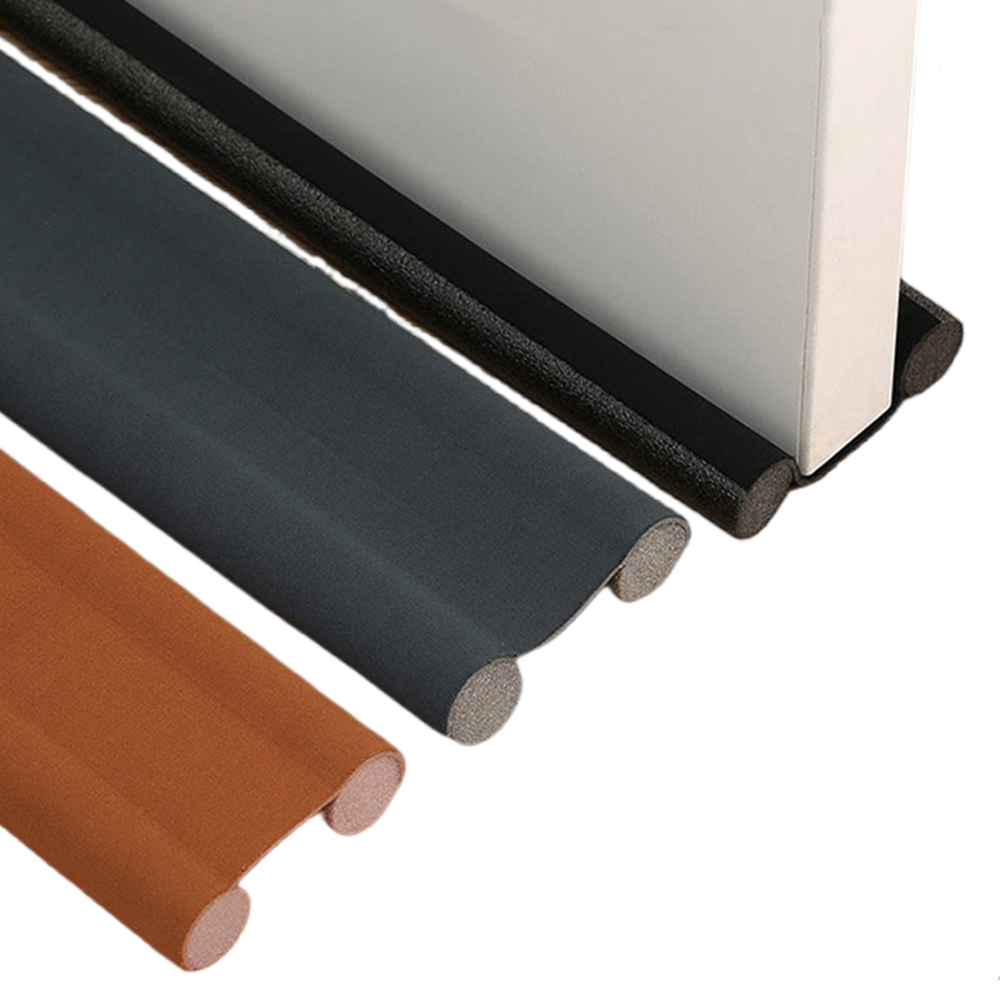

- Universal Fitting: Custom length (450~1200mm); adhesive & mechanical mounting

- Extrusion & Precision Cutting: Ensures dimensional accuracy & seamless installation under diverse thresholds

- ISO 9001/ISO 14001 Certified Manufacturing

Manufacturing Process Flow of Door Bottom Draught Excluder

- Raw Material Selection: Sourcing premium grade silicone resin and aircraft-grade 6063 aluminum alloy. Aluminum complies with RoHS/EN-573 standards for eco-safety.

- Extrusion Process: Silicone and aluminum extruded through precise dies; this step assures perfect blade flexibility & stable body shape. (See photo below)

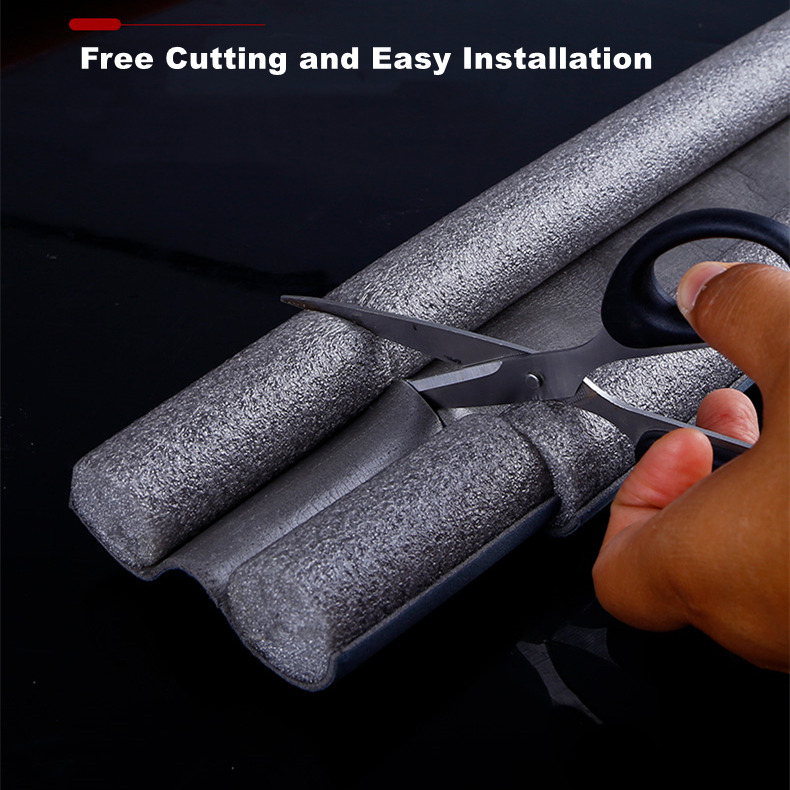

- Precision CNC Cutting: Blade and body cut to specified sizes (customizable from 450mm – 1200mm); tolerance ±0.3mm.

- Punching/Drilling: CNC-punched holes for both adhesive and mechanical screw installation variants.

- Anodizing & Surface Treatment: Aluminum anodized for anti-corrosion, enhancing endurance in aggressive environments (certified to ISO 7599).

- Quality Inspection: 100% dimensional and cycle-durability test, in compliance with ISO 9001 standards (certificates provided on request).

- Packing & Dispatch: Protective packaging in cartons; laser-marked QR for traceability.

- Petrochemical plants (gas-tight room separation)

- Metallurgy workshops (dust/wind control)

- Commercial HVAC (ASHRAE-compliant)

- Food processing (FDA-grade options)

- Municipal water supply rooms — improved corrosion & humidity resistance

- Residential & Large-Estate Energy Efficiency Projects

Data Visualization: Technical Specification and Product Performance Charts

Vendor Comparison: What Sets QZSeals Apart?

| Parameter | QZSeals | General OEM | Budget Brands |

|---|---|---|---|

| Material Quality | Premium silicone + Aircraft-grade anodized aluminum | PVC or standard aluminum | PVC/composite plastics |

| Certifications | ISO 9001, RoHS, EN573 | ISO 9001 | None/Partial |

| Custom Sizing | Yes (450–1200mm, ±0.3mm) | Limited | No |

| Cycle Durability | >250,000 | >80,000 | >30,000 |

| After-sales Support | 1:1 engineering support + Global logistics | Limited | No |

| Lead Time | 7~15 days (stock: 24h) | 15–30 days | 30–45 days |

Custom Solutions & Engineering Services

- OEM/ODM Customization: Tailor your door bottom draught excluder for unique threshold heights, colors (RAL/Anodized), and gasket hardness (Shore A 35–90).

- Application Engineering: Direct support for projects in petrochemical containment, ultra-clean room sealing, marine vessels (salt-mist resistance), and fire-rated doors.

- Advanced Prototyping: 3D CAD design review and on-site fitment samples within 7 days

- Labeling/Traceability: All excluders batch-coded for compliance trace, with material certificates.

Prototypes: 7-14 days.

Bulk orders: 12-18 days.

Urgent/stock supply: shipped in 24 hours (subject to availability).

Application Scenarios & Real-World Case Studies

- Data Center Project (2023, East Asia): Implemented 560 customized door bottom draught excluder units — Result: 7.6% reduction in annual HVAC energy cost (measured by in-line monitor, ISO 50001).

- Food Processing Facility (EU): FDA-grade seals used in refrigerated and dry storage zones; compliance with ISO 22000 HACCP standards.

- Oil & Gas Refinery (Middle East): Fire-rated under door draught stopper with C4 marine anodizing withstands chemical vapor and abrasive dust.

- Residential High-rise Retrofit: Replacement of old rubber threshold strips improved bottom seal door performance, with verified 19% air leakage reduction (per ASTM E283).

“The new door bottom draught excluders from QZSeals have notably reduced draughts and external noise. Installation took under 10 minutes per door and has already improved thermal comfort — Facility Manager, Shanghai.”

Professional FAQ: Technical Deep Dive

Trust & Support: Certifications, Partners & Customer Care

- Certifications: ISO 9001:2015, ISO 14001:2015, RoHS, FDA (on request), ANSI/BHMA compliance.

- Partner Network: Collaboration with industry leaders—Honeywell, Siemens Building Technologies, Sinopec, and domestic residential developers.

- Service: International customer support, on-site technical consulting, and real-time tracking of each batch.

- Warranty: 3-year material warranty, free spare parts for all door bottom draught excluder variants.

- QC Flow: Traceable production batches with batch certificates delivered electronically.

Explore the full line of top-performance sealing strips, stoppers & excluders at QZSeals official site.

References & Further Reading

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025