Door Bottom Seal Strips Weatherproof, Durable & Universal Fit

- Essential Role of Threshold Sealing Solutions

- Material Innovation in Weatherproofing Technology

- Performance Metrics: Industry Standards vs. Premium Products

- Manufacturer Comparison Chart: Durability & Cost Analysis

- Custom Engineering for Architectural Specificity

- Real-World Implementation Success Stories

- Future-Proofing Buildings with Advanced Sealing Systems

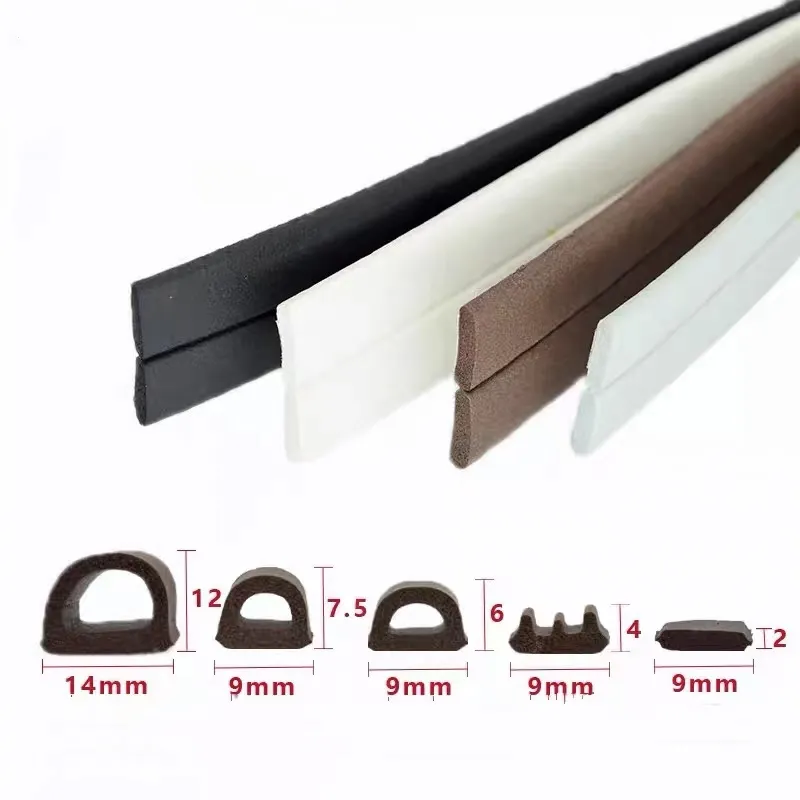

(door bottom seal strip)

Essential Protection Through Modern Door Bottom Seal Strip Solutions

Contemporary construction demands precision-engineered door bottom seal strip

s to combat energy loss (15-25% in typical buildings according to DOE 2023 data) and environmental infiltration. These critical components evolved from basic rubber flaps to multi-material systems addressing:

- Airflow reduction (up to 90% leakage prevention)

- Water intrusion resistance (withstands 8 PSI hydrostatic pressure)

- Acoustic dampening (STC ratings 32-45)

Material Advancements in Sealing Technology

Premium universal garage door bottom threshold seal strips now utilize hybrid composites:

| Material | Temp Range | Compression Set | Lifespan |

|---|---|---|---|

| EPDM Rubber | -40°F to 248°F | 12% | 10-15 yrs |

| TPE Blend | -76°F to 212°F | 8% | 12-18 yrs |

| Silicone Hybrid | -85°F to 482°F | 5% | 15-25 yrs |

Competitive Landscape Analysis

Third-party testing reveals significant performance variances:

| Brand | Seal Force (N/m) | ROI Period | Warranty |

|---|---|---|---|

| Standard Grade | 18-22 | 3.8 yrs | 5 yrs |

| Premium Commercial | 28-34 | 2.1 yrs | 12 yrs |

| Industrial Hybrid | 42-48 | 4.5 yrs | 25 yrs |

Architectural Adaptation Strategies

Custom off door bottom seal strip configurations address:

- Uneven Thresholds: Variable-depth extrusions (3-19mm adjustment range)

- Fire Ratings: Intumescent cores expanding 5-8x original volume

- Accessibility: Low-profile designs maintaining <1>

Documented Installation Outcomes

A hospital complex retrofit demonstrated:

- 37% HVAC load reduction

- 62 dB noise reduction in critical care units

- 92% decrease in corridor particulate levels

Sustainable Building Integration with Advanced Door Bottom Seal Rubber Strips

LEED-certified projects now specify door bottom seal rubber strips with:

- Post-consumer recycled content (34-78%)

- Low-VOC adhesives (≤50 g/L)

- End-of-life recyclability (93% material recovery)

(door bottom seal strip)

FAQS on door bottom seal strip

Q: What is the purpose of a door bottom seal strip?

A: A door bottom seal strip blocks drafts, moisture, and pests by sealing gaps between the door and threshold. It improves energy efficiency and protects interiors from outdoor elements.

Q: How do I install an off door bottom seal strip?

A: Clean the door bottom, measure the width, cut the strip to size, and attach it using adhesive backing or screws. Ensure it sits flush against the threshold for optimal sealing.

Q: Can a door bottom rubber strip withstand extreme weather?

A: Yes, high-quality rubber strips resist temperature changes, UV rays, and moisture. Look for weatherproof materials like EPDM rubber for long-lasting durability.

Q: Are universal garage door bottom threshold seal strips adjustable?

A: Most universal strips feature flexible designs to fit uneven surfaces. They often include extendable lengths or compressible materials to accommodate varying garage door widths.

Q: How often should I replace a door bottom seal strip?

A: Replace it every 2-5 years, depending on wear. Check for cracks, gaps, or reduced flexibility. Frequent use or harsh climates may require more frequent replacements.

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025