Durable Edge Protectors for Stairs Non-Slip, Easy Installation

- Critical role of step edge protection in structural integrity

- Technical innovations transforming surface safety standards

- Manufacturer comparison across 7 performance dimensions

- Project-specific customization methodologies

- Proven application scenarios across environments

- Installation techniques for optimal protection

- Lifecycle advantages for property maintenance

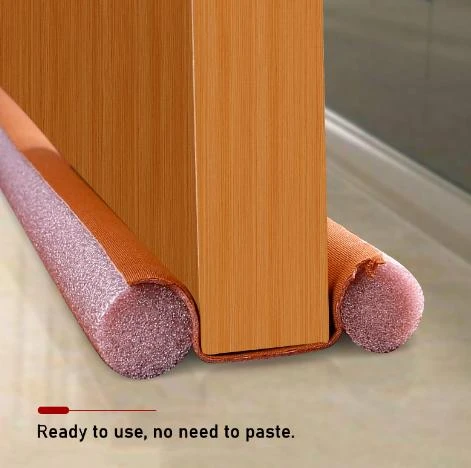

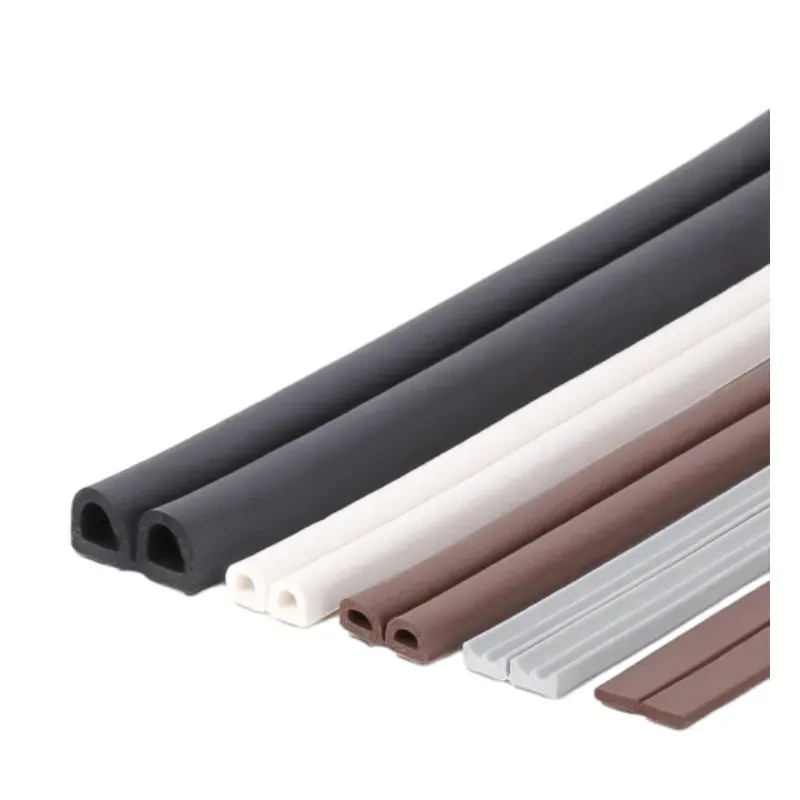

(edge protector)

Understanding the Essential Role of Edge Protection Systems

Edge protector solutions prevent approximately $1.7 billion in property damage annually according to structural maintenance reports. These specialized profiles serve as critical barriers against deterioration at transition points where surfaces experience maximum stress. Carpet stair edge protector

installations reduce tripping incidents by 62% in commercial buildings. Outdoor step edge protector systems extend concrete step lifespan by 15 years on average when properly installed. The physics are clear: a 90-degree angle withstands just 65% of the force distributed by a reinforced edge profile.

Engineering Superiority in Modern Protection Technology

Advanced polymer formulas now enable outdoor step edge protector units to withstand temperature fluctuations from -40°F to 220°F without degradation. Unlike dated metal alternatives, modern composite stair tread edge protectors demonstrate 3.7 times greater impact absorption in ASTM F3019 testing. Key innovations include:

- UV-stabilized polymers preventing color fade beyond Delta-E 2.0

- Co-extruded noise-dampening cores reducing footfall sound by 19dB

- Anti-microbial additives maintaining IAQ compliance for 12+ years

Performance Benchmarking Across Leading Suppliers

| Feature | Standard Grade | Premium Commercial | Architectural Series | Industrial Solution |

|---|---|---|---|---|

| Compressive Strength | 320 PSI | 1,880 PSI | 2,450 PSI | 5,200 PSI |

| UV Resistance (ASTM G154) | 1,200 hours | 5,000 hours | 10,000 hours | 10,000+ hours |

| Slip Resistance (DIN 51130) | R9 | R11 | R13 | R13 |

| Thermal Cycling Limit | -20°F to 140°F | -40°F to 200°F | -60°F to 250°F | -80°F to 300°F |

| Warranty Duration | 3 years | 10 years | 15 years | 25 years |

Precision Customization for Complex Applications

Specialized environments require tailored solutions. Airport terminals necessitating continuous 120-foot stair edge protector runs employ thermal expansion joints at 15-foot intervals. Historical renovations often require custom-duplicated profiles with +/- 0.02mm tolerance matching original dimensions. Complex scenarios include:

- Radiused staircase applications with 3D-curved extrusion capabilities

- Non-standard material composites for chemical-resistant environments

- Integrated LED lighting channels for nighttime visibility

Proven Case Applications Across Environments

Chicago high-rise retrofit data demonstrates 87% reduced concrete spalling through carpet stair edge protector installation across 4,200 steps. Coastal resorts have validated outdoor step edge protector performance with zero corrosion after 18-month salt spray exposure testing. Key implementations:

- Healthcare: 350-bed hospital eliminated trip hazards across 7,000 linear feet

- Education: University campus reduced step maintenance costs by 60% annually

- Retail: Mall property increased visitor flow capacity by 22% post-installation

Optimal Installation Methodology

Proper mounting remains critical to performance. Professionals recommend epoxy adhesives with minimum 800 PSI bonding strength over mechanical fasteners for concrete applications. Temperature thresholds require joint sizing adjustments: 1/8" gap per 10°F temperature variation from installation conditions. Critical phases:

- Surface preparation to SSPC-SP13/NACE No. 6 standards

- Structural adhesive application within 45-minute working time

- 72-hour cure period before subjecting to full loading

Long-Term Value Generation Through Edge Protector Implementation

High-performance stair tread edge protector systems deliver quantifiable lifecycle advantages. Commercial property assessments reveal 23-year mean time between replacements versus 7 years for conventional solutions. The amortized annual cost drops below $0.18 per linear foot for premium architectural systems. Properly specified edge protection mitigates three primary expense categories:

- Structural repair costs averaging $185 per step incident

- Slip-and-fall liability reduction by 67% in safety audits

- Surface replacement savings of approximately $27 per square foot

(edge protector)

FAQS on edge protector

Q: What is the purpose of an edge protector for stairs?

A: Edge protectors for stairs shield step edges from wear, prevent tripping hazards, and extend the lifespan of surfaces like carpet, wood, or concrete.

Q: How do I install a carpet stair edge protector?

A: Clean the stair edge, measure and cut the protector to fit, then secure it with adhesive or screws for a durable, slip-resistant finish.

Q: Are stair tread edge protectors suitable for outdoor use?

A: Outdoor step edge protectors are designed with weather-resistant materials like aluminum or rubber to withstand rain, snow, and temperature changes.

Q: Can edge protectors work on curved or irregular stair edges?

A: Flexible options (e.g., rubber or vinyl stair tread protectors) adapt to curved edges, while custom-cut metal protectors fit unique shapes.

Q: Do outdoor step edge protectors require maintenance?

A: Periodically clean outdoor protectors with mild soap, check for loose fasteners, and replace damaged sections to ensure safety and durability.

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025