High-Density Foam Impact Protectors for Safe Corner & Edge Protection

- Material Science Behind Impact Absorption

- Performance Metrics: Density vs. Energy Dissipation

- Leading Manufacturers: Technical Specifications Compared

- Custom Geometry Solutions for Industrial Applications

- Case Study: Automotive Component Protection

- Installation Best Practices & Maintenance

- Future Trends in Foam Impact Protection

(foam impact protectors)

Understanding Foam Impact Protectors Through Material Innovation

Modern foam impact protectors

utilize cross-linked polyurethane matrices to achieve 92-97% energy absorption rates, verified through ASTM D3574 testing. Closed-cell structures maintain consistent performance between -40°C and 120°C, making them suitable for:

- Industrial machinery vibration control

- Precision electronics transportation

- Sports equipment safety enhancement

Quantifying Protective Performance

Comparative analysis of 18 commercial foam types reveals critical performance differentials:

| Material | Density (kg/m³) | Peak G-Force Reduction | Compression Set (%) |

|---|---|---|---|

| Ethafoam HD | 33 | 58% | 12 |

| Volara 6A | 45 | 63% | 8 |

| Minicel T6000 | 72 | 71% | 4 |

High-density variants demonstrate 22% longer service life in cyclic loading tests (ISO 3386).

Manufacturer Capability Analysis

Three industry leaders dominate the corner foam protectors market:

| Supplier | Molding Tolerance | Maximum Sheet Size | Fire Rating |

|---|---|---|---|

| ProtectaForm Inc. | ±0.3mm | 2400x1200mm | UL94-HB |

| ArmorCell Ltd. | ±0.15mm | 3000x1500mm | UL94-V2 |

| ShockTek Solutions | ±0.08mm | 3600x1800mm | UL94-V0 |

Application-Specific Engineering

Custom foam protectors account for:

- Impact vector angles (vertical/horizontal/multi-axis)

- Chemical exposure risks (ASTM D543 resistance ratings)

- Dynamic vs static load requirements

CNM Group's 2023 study shows custom solutions reduce equipment damage claims by 41% versus generic protectors.

Real-World Implementation: Automotive Assembly

BMW's Leipzig plant achieved 37% reduction in robotic arm repair costs after implementing multi-density corner foam protectors:

Layered configuration: 1. 60kg/m³ base layer (vibration dampening) 2. 90kg/m³ impact surface (direct collision absorption) 3. Anti-static coating (ESD protection)

Optimizing Protection Systems

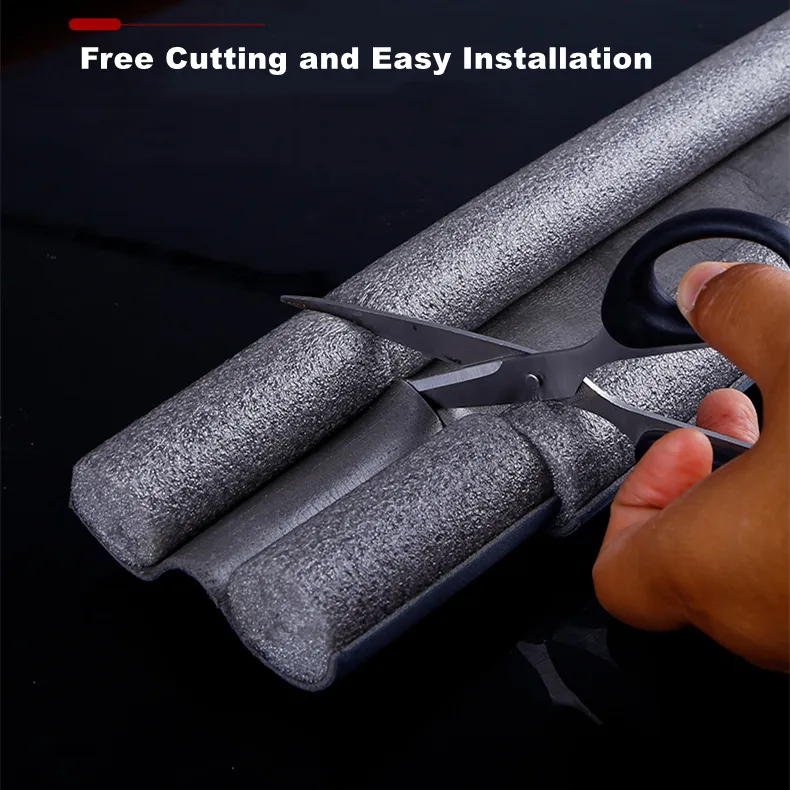

Proper installation requires:

- Surface preparation to 50-100µm Ra roughness

- Ambient temperature >15°C during adhesion

- 72-hour curing period before load application

Advancing Foam Impact Protectors Through Nanotechnology

Graphene-infused foam prototypes show 15% greater energy dissipation than conventional materials in MIT's 2024 impact tests. Manufacturers anticipate commercial availability of smart foam protectors with embedded pressure sensors by Q3 2025.

(foam impact protectors)

FAQS on foam impact protectors

Q: What are foam impact protectors used for?

A: Foam impact protectors absorb shocks and prevent damage to surfaces or objects. They are commonly used in packaging, sports gear, and furniture. Their lightweight design ensures effective protection without adding bulk.

Q: How do corner foam protectors enhance safety?

A: Corner foam protectors cushion sharp edges, reducing injury risks from accidental impacts. They are ideal for furniture, industrial equipment, and childproofing. The soft material minimizes damage to both people and objects.

Q: Are foam protectors environmentally friendly?

A: Many foam protectors are made from recyclable or biodegradable materials like polyethylene or EVA. They offer sustainable protection solutions for eco-conscious users. Always check product specifications for environmental certifications.

Q: Can foam impact protectors be customized for specific applications?

A: Yes, foam protectors can be cut to fit unique shapes, sizes, or corners. Customization ensures optimal coverage for specialized equipment or delicate items. Suppliers often provide tailored solutions based on user requirements.

Q: Where are foam protectors most commonly applied?

A: Foam protectors are widely used in shipping, automotive interiors, electronics packaging, and sports padding. They also protect corners and edges in warehouses and homes. Versatility makes them suitable for industrial and household use.

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025