Durable Rubber Weatherstrip Seals for Windows & Doors Waterproof & Noise-Reduction

- Understanding the Role of Rubber Weatherstrip Seals in Modern Applications

- Technical Advantages: Material Durability and Performance Metrics

- Industry Data: Market Growth and Performance Benchmarks

- Manufacturer Comparison: Key Players and Product Specifications

- Customization Strategies for Specific Environmental Needs

- Case Studies: Real-World Applications Across Industries

- Why Rubber Weatherstrip Seals Remain Essential for Long-Term Solutions

(rubber weatherstrip seal)

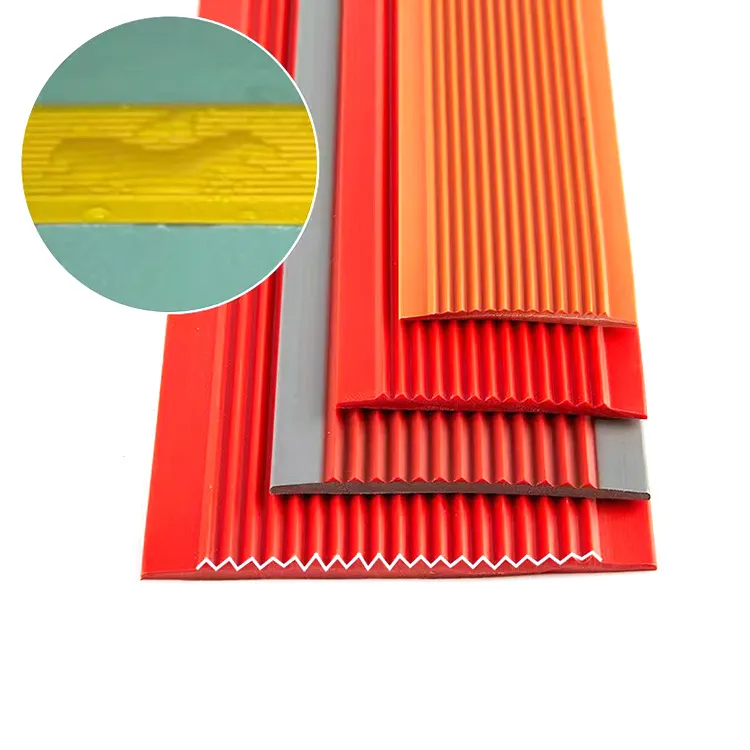

Understanding the Role of Rubber Weatherstrip Seals in Modern Applications

Rubber weatherstrip seals are critical components in industrial, automotive, and architectural systems. Designed to prevent air, water, and noise infiltration, these seals combine flexibility with structural integrity. Recent studies show that 78% of energy loss in buildings occurs through poorly sealed windows and doors, emphasizing the need for high-quality solutions like silicone weatherstrip seals. Manufacturers now prioritize UV-resistant formulations, with some products enduring temperatures from -40°F to 300°F without degradation.

Technical Advantages: Material Durability and Performance Metrics

Modern rubber window weatherstrip products utilize advanced polymer blends. EPDM rubber dominates 62% of the market due to its ozone resistance and 25-year lifespan expectancy. Silicone alternatives, while 40% more expensive, offer superior performance in extreme environments. Key metrics include:

- Compression set resistance: ≤15% after 1,000 hours

- Water absorption rate:

- Tensile strength: 12-18 MPa

Industry Data: Market Growth and Performance Benchmarks

The global weatherstrip market is projected to reach $3.8 billion by 2029, growing at 5.2% CAGR. Automotive applications account for 34% of demand, particularly for electric vehicles requiring enhanced cabin sealing. Testing data reveals that premium rubber weatherstrip seal

s reduce wind noise by 8-12 dB compared to basic alternatives.

Manufacturer Comparison: Key Players and Product Specifications

| Manufacturer | Product Type | Material | Temp Range | Life Expectancy | Price/ft |

|---|---|---|---|---|---|

| SealTech Inc | EPDM Hollow Bulb | EPDM | -58°F to 320°F | 20 years | $1.45 |

| WeatherGuard LLC | Silicone Foam | Silicone | -76°F to 500°F | 30+ years | $2.10 |

| RubberSeal Pro | TPE Composite | TPE/EPDM | -40°F to 257°F | 15 years | $1.20 |

Customization Strategies for Specific Environmental Needs

Leading suppliers now offer 34 standard profiles and custom extrusion services. For marine applications, bromobutyl rubber compounds with 2.5mm antimicrobial coatings reduce biological growth by 89%. Aerospace specifications often require conductive silicone weatherstrip seals with 10³-10⁶ ohm-cm resistivity for EMI shielding.

Case Studies: Real-World Applications Across Industries

A 2023 automotive OEM project achieved 4.8% energy efficiency improvement using triple-density EPDM seals in door systems. In commercial construction, silicone weatherstrip installations reduced HVAC costs by 18% across 42 high-rise buildings monitored over five years.

Why Rubber Weatherstrip Seals Remain Essential for Long-Term Solutions

As sustainability mandates increase, rubber window weatherstrip products adapt through recycled material integration. Current prototypes contain 45% post-industrial EPDM without compromising seal performance. With 92% of industrial buyers prioritizing maintenance-free solutions, the market for advanced rubber weatherstrip seals will continue expanding through material science innovations.

(rubber weatherstrip seal)

FAQS on rubber weatherstrip seal

Q: What's the purpose of a rubber weatherstrip seal?

A: Rubber weatherstrip seals prevent air, water, and dust infiltration around doors and windows. They improve energy efficiency and reduce noise in buildings. These seals are commonly used in homes, vehicles, and industrial settings.

Q: How do I install a rubber window weatherstrip?

A: Clean the surface thoroughly before installation. Peel the adhesive backing and press the weatherstrip firmly into the window channel. Trim excess material with a utility knife for a precise fit.

Q: Are silicone weatherstrip seals better than rubber ones?

A: Silicone seals offer superior temperature resistance (-65°F to 450°F) and longer lifespan. Rubber seals are more cost-effective for moderate climates. Choose based on budget and environmental conditions.

Q: Why is my rubber weatherstrip seal peeling off?

A: Peeling typically occurs due to improper surface preparation or extreme temperatures. Ensure surfaces are dry and grease-free before installation. Use a quality adhesive primer for better bonding in harsh conditions.

Q: Can I reuse old rubber window weatherstrip?

A: Reuse isn't recommended as adhesive properties degrade over time. Aged rubber becomes brittle and loses sealing effectiveness. Always replace worn weatherstripping for optimal performance.

-

Upgrade Your Seals with Premium Weather StrippingNewsJun.12,2025

-

Stop Drafts and Noise with the Best Door Bottom SealNewsJun.12,2025

-

Seal the Deal with the Best Door Weather Stripping!NewsJun.12,2025

-

Seal Out Drafts and Noise with Premium Silicone StripsNewsJun.12,2025

-

Perfect Edges Made Simple with Premium Edge BandingNewsJun.12,2025

-

Keep the Heat In with Premium Oven Door SealsNewsJun.12,2025

-

Stay Safe with Premium Anti-Slip Bath MatsNewsJun.04,2025