Safe & Secure Bathtub Mat: Anti-Slip for Shower Safety

The Imperative Role of Advanced Drainage Non-Slip Mats in Industrial and Commercial Safety

In high-traffic commercial and industrial environments, maintaining a safe and hygienic flooring surface is paramount. The increasing awareness of workplace safety, coupled with stringent regulatory standards, has propelled the demand for high-performance anti-slip solutions. Among these, the advanced bathtub mat, often engineered as a drainage non-slip mat or commercial PVC floor mat, stands out as a critical component in preventing slips, trips, and falls. This article delves into the technical specifications, manufacturing intricacies, diverse application scenarios, and strategic advantages of these essential safety solutions.

The global market for anti-slip flooring solutions, including specialized industrial mats, is projected to grow significantly, driven by sectors like hospitality, healthcare, manufacturing, and food processing. According to recent market analyses, the demand for durable and effective anti slip mat solutions is expected to reach USD 5.2 billion by 2028, with a compound annual growth rate (CAGR) of 6.5%. This growth is primarily fueled by heightened safety regulations, increased insurance costs associated with workplace injuries, and the persistent need for hygienic and easy-to-maintain floor surfaces in various operational settings. The modern anti skid mat is no longer a simple rubber sheet but a meticulously engineered system designed for optimal safety and longevity, proving itself indispensable as a reliable mat for shower areas or expansive industrial floors.

Product Overview: Drainage Non Slip Mat, Commercial PVC Floor Mat

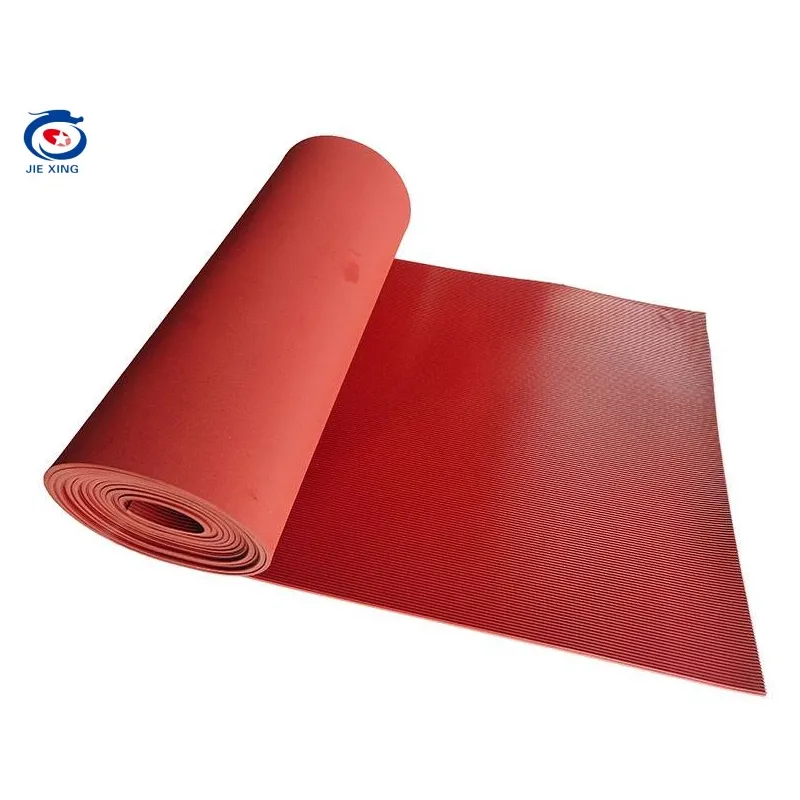

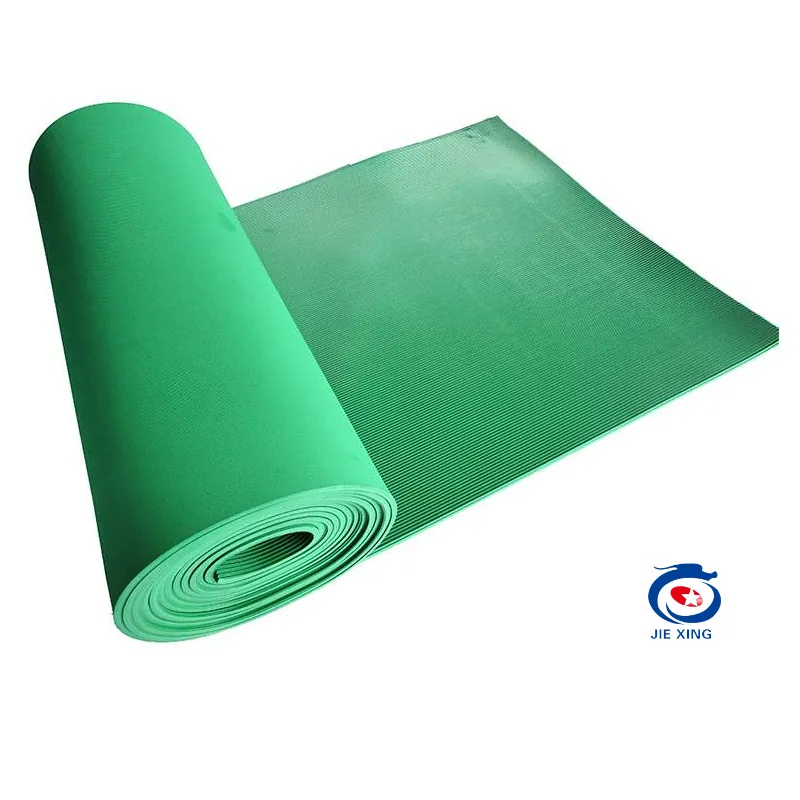

The Drainage Non Slip Mat, Commercial PVC Floor Mat offered by QZSEALS represents the pinnacle of engineering in anti-fatigue and safety flooring. Designed specifically for environments where moisture, grease, or spills are prevalent, this robust solution provides superior traction and facilitates efficient liquid drainage. Its construction from high-grade PVC ensures exceptional durability, resistance to harsh chemicals, and ease of cleaning, making it an indispensable asset across a multitude of commercial and industrial applications. This specialized mat minimizes hazards and enhances worker comfort, offering critical anti slip for mats properties.

Key Technical Specifications:

| Parameter | Specification |

|---|---|

| Material Composition | High-Density Virgin PVC (Polyvinyl Chloride) |

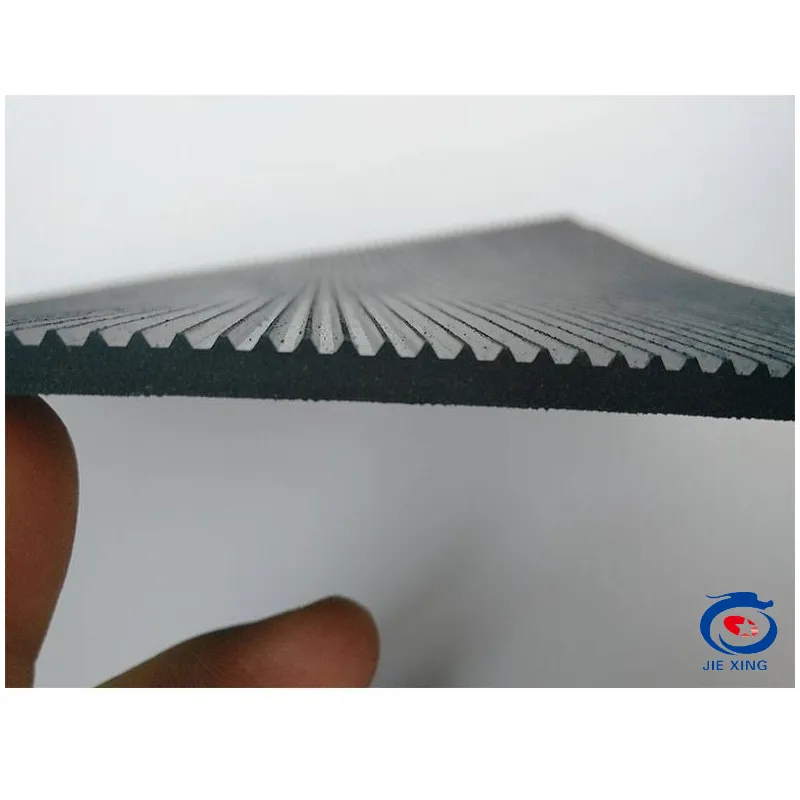

| Thickness Range | Typically 10mm - 14mm (customizable) |

| Weight | Approx. 4.5 - 6.0 kg/m² |

| Surface Design | Open-grid design with textured surface for enhanced anti-slip properties |

| Anti-Slip Rating | Exceeds R10 (DIN 51130) and Coefficient of Friction (COF) > 0.6 (ASTM F1677) |

| Temperature Resistance | -20°C to +60°C |

| Chemical Resistance | Resistant to most industrial cleaning agents, mild acids, alkalis, and animal fats. |

| Shore Hardness (Type A) | Approx. 65-75 (ASTM D2240) |

| Fire Rating | Bfl-s1 (EN 13501-1) or equivalent upon request |

| Standard Sizes | Rolls: 0.9m x 15m, 1.2m x 15m; Tiles: 0.5m x 0.5m (interlocking) |

| Certifications | ISO 9001:2015, REACH, RoHS Compliant |

The Advanced Manufacturing Process of Anti-Slip Mats

The production of a high-quality bathtub mat or commercial anti slip mat involves a meticulously controlled manufacturing process, leveraging advanced polymer extrusion and molding techniques to ensure consistent product performance and durability. Adherence to international quality standards, such as ISO 9001, is integrated throughout every stage, ensuring each anti skid mat meets rigorous specifications.

Process Flow:

1. Raw Material Sourcing & Preparation

High-grade virgin PVC resin pellets are sourced, ensuring compliance with REACH and RoHS directives for environmental safety. Additives for UV stabilization, anti-fungal properties, colorants, and plasticizers are precisely measured and pre-mixed to achieve the desired material characteristics, including flexibility and resistance crucial for a durable anti slip for mats solution.

2. Extrusion & Molding

The PVC compound is fed into high-precision extruders, where it is heated and melted. The molten PVC is then extruded through custom dies to form the mat's intricate open-grid pattern. For interlocking tiles, injection molding techniques are employed to achieve precise dimensions and robust connectors. This process is crucial for creating the distinctive drainage channels and textured anti skid mat surface.

3. Cooling & Curing

After extrusion/molding, the hot mat material passes through a controlled cooling system (typically water baths or air cooling) to solidify the PVC structure and prevent deformation. This step is critical for maintaining dimensional stability and material integrity, which contributes to the mat's long service life.

4. Cutting & Finishing

The cooled material is then precisely cut to standard roll lengths or individual tile dimensions using automated cutting machines. Edges are often chamfered or beveled to reduce trip hazards and ensure a smooth transition from adjacent flooring. Quality control checks for dimensions, surface finish, and edge integrity are performed on every mat for shower or industrial use.

5. Quality Assurance & Testing

Rigorous testing is conducted on samples from each production batch. This includes:

- Anti-Slip Performance: Tested using methods like DIN 51130 (R-values) or ASTM F1677 (COF wet/dry).

- Material Durability: Tensile strength, tear resistance (ASTM D412), abrasion resistance.

- Chemical Resistance: Exposure to common industrial chemicals.

- Dimensional Stability: Ensuring consistency under varying temperatures.

6. Packaging & Shipment

Finished mats are rolled and securely packaged for protection during transit. Interlocking tiles are bundled. Proper labeling ensures traceability and product identification. Our efficient logistics ensure timely delivery to target industries such as food processing, petrochemicals, metallurgy, and water supply & drainage, where these mats provide critical energy saving and safety benefits.

Technical Advantages and Performance Benefits

The design and material science behind a high-grade bathtub mat are optimized to deliver multifaceted advantages in demanding operational environments, making it a superior anti slip mat choice.

- Superior Anti-Slip Performance: The open-grid design, combined with a textured surface and specific PVC Shore Hardness, provides an exceptionally high Coefficient of Friction (COF), even in the presence of water, grease, or chemicals. This drastically reduces the risk of slips and falls, critical for compliance with OSHA and local safety regulations. Our mats consistently achieve high R-values (e.g., R10-R12) for barefoot and shod slip resistance.

- Efficient Drainage Capabilities: The raised profile and open construction allow liquids and debris to flow beneath the mat, keeping the standing surface dry and clean. This is vital for hygiene in food processing, healthcare, and aquatic facilities, preventing bacterial growth and maintaining a clean anti slip mat environment, particularly important for any mat for shower use.

- Chemical and Corrosion Resistance: Manufactured from specialized PVC compounds, these mats exhibit excellent resistance to a wide range of industrial chemicals, acids, alkalis, oils, and animal fats. This inherent property ensures a long service life in environments where corrosive spills are common, unlike inferior rubber or foam mats that degrade rapidly. This is a key advantage for an anti skid mat in harsh conditions.

- Ergonomic Anti-Fatigue Properties: The flexible yet robust PVC structure provides a cushioning effect, significantly reducing strain on workers' feet, legs, and backs. This ergonomic benefit improves comfort, reduces fatigue, and can lead to increased productivity and reduced absenteeism, an often-overlooked advantage of a well-chosen anti slip for mats solution.

- Exceptional Durability and Longevity: Engineered for heavy-duty commercial use, these mats are resistant to tearing, abrasion, and punctures. Their robust construction ensures they withstand constant foot traffic, cart movement, and industrial cleaning methods, delivering a superior return on investment compared to disposable alternatives.

- Hygiene and Ease of Maintenance: The non-porous PVC material inhibits the growth of mold, mildew, and bacteria. The open-grid design facilitates easy cleaning; mats can be simply hosed down or steam cleaned, making them ideal as a mat for shower areas or commercial kitchens where sanitation is critical.

Diverse Application Scenarios

The versatility of the Drainage Non Slip Mat, Commercial PVC Floor Mat makes it an indispensable safety solution across a broad spectrum of industries requiring an effective anti slip for mats solution.

- Commercial Kitchens & Food Service: Crucial for maintaining hygiene and preventing slips on wet and greasy floors. They facilitate drainage around sinks, fryers, and dishwashing areas, providing a safe anti skid mat for kitchen staff.

- Industrial Workstations & Manufacturing Plants: Ideal for areas prone to oil, coolant, or chemical spills. They enhance worker safety and reduce fatigue at assembly lines, machining centers, and heavy equipment operation zones.

- Healthcare Facilities & Laboratories: Used in washrooms, operating theatres, sterile processing areas, and laboratories where spills are common and hygiene is critical. A reliable bathtub mat or shower mat contributes to infection control.

- Swimming Pools, Spas & Changing Rooms: Essential for preventing slips on wet surfaces. The excellent drainage keeps water from pooling, providing a safe walking surface. This acts as a highly effective mat for shower areas and pool surrounds.

- Marine & Offshore Environments: Resilient to saltwater and harsh conditions, these mats are perfect for boat decks, galleys, and industrial platforms where constant moisture poses a slip hazard.

- Bars & Beverage Service Areas: Manage spills from drinks, ice, and broken glass, ensuring safety for staff and customers alike.

Vendor Comparison: Evaluating Commercial Anti-Slip Mat Providers

Choosing the right vendor for industrial and commercial anti slip mat solutions is critical for long-term safety and operational efficiency. While many offer basic products, key differentiators lie in material quality, technical compliance, customization capabilities, and post-sales support. Below is a comparative analysis, highlighting why a high-performance anti skid mat from a reputable supplier is a superior investment:

| Feature/Vendor | QZSEALS (Drainage Non Slip Mat) | Competitor A (Rubber Mat) | Competitor B (EVA Foam Mat) |

|---|---|---|---|

| Primary Material | High-Density Virgin PVC | Recycled Rubber | EVA Foam |

| Anti-Slip Rating (R-value/COF) | R10-R12 / COF > 0.6 wet | R9-R10 / COF ~ 0.5 wet | R8-R9 / COF ~ 0.4 wet |

| Drainage Efficiency | Excellent (Open Grid) | Good (Holes, but can clog) | Limited (Solid or small perforations) |

| Chemical Resistance | Superior (Acids, Alkalis, Oils, Fats) | Good (Limited to specific chemicals) | Poor (Degrades with many chemicals/oils) |

| Durability/Service Life | Excellent (5-8 years typical) | Good (3-5 years, can crack/dry) | Fair (1-3 years, prone to tearing/wear) |

| Hygiene/Ease of Cleaning | Excellent (Non-porous, easy to hose/steam clean) | Good (Can be porous, harder to deep clean) | Fair (Porous, absorbs liquids, harder to sanitize) |

| Certifications (Example) | ISO 9001, REACH, RoHS | ISO 9001 (Material specific) | Basic safety |

| Customization Options | High (Size, Color, Interlocking, Edges) | Moderate (Size, some patterns) | Low (Standard sizes/colors) |

QZSEALS, with over 15 years of specialization in industrial sealing and flooring solutions, has built a reputation for delivering products that consistently exceed industry benchmarks. Our commitment to quality is underscored by our ISO 9001:2015 certification and a robust client portfolio that includes major players in the petrochemical and water treatment sectors. This extensive experience ensures that every anti slip mat we produce is engineered for peak performance and reliability, offering superior anti slip for mats properties.

Customized Solutions for Specialized Needs

Recognizing that off-the-shelf solutions may not always address the unique demands of every industrial or commercial environment, QZSEALS offers comprehensive customization options for our Drainage Non Slip Mats. Our engineering team collaborates closely with clients to develop bespoke solutions that precisely fit operational requirements.

- Tailored Dimensions: Mats can be custom-cut to exact specifications, whether for irregular floor plans, specific workstation sizes, or large-area coverage, minimizing waste and ensuring seamless integration. This applies to any application, from a specialized bathtub mat to extensive industrial flooring.

- Color Matching & Branding: Beyond standard black or grey, mats can be produced in a variety of colors to match brand guidelines, delineate safety zones, or improve visual aesthetics. Logos or specific safety messages can also be integrated into the mat design, enhancing the utility of the anti skid mat.

- Enhanced Material Properties: For extreme conditions, we can adjust PVC formulations to enhance specific properties such as higher temperature resistance, increased chemical inertness to particular reagents, or superior UV stability for outdoor applications, ensuring a robust anti slip mat in any setting.

- Interlocking Systems & Edging: Custom interlocking mechanisms can be designed for specific tile configurations, or specialized ramped edging can be added to further reduce trip hazards and facilitate cart traffic, especially beneficial for a mat for shower or high-traffic areas.

Application Case Studies and Client Successes

Real-world implementations demonstrate the tangible benefits of our Drainage Non Slip Mats, showcasing their effectiveness as a reliable anti slip for mats solution:

Case Study 1: Large-Scale Food Processing Facility

"Prior to implementing QZSEALS mats, our meat processing lines experienced an average of 3-4 slip-related incidents monthly, leading to worker injuries and production downtime. We needed a heavy-duty anti slip mat solution."

Challenge: A major food processing client faced persistent slip hazards in their wash-down areas and processing lines due to constant moisture, animal fats, and cleaning agents. Existing rubber mats deteriorated quickly and offered insufficient drainage.

Solution: We supplied custom-sized Drainage Non Slip Mats (Commercial PVC Floor Mat type) for over 1,500 square meters of their facility. The open-grid PVC design was chosen for its superior chemical resistance and drainage capacity, ensuring fluids were channeled away effectively. This proved to be an ideal anti skid mat solution for their specific needs.

Outcome: Within six months of installation, slip-related incidents plummeted by 85%. Worker feedback highlighted improved comfort and a perception of enhanced safety. The mats demonstrated exceptional resistance to daily chemical cleaning regimens, projecting a service life far exceeding previous solutions, leading to significant cost savings in replacement and injury claims. This success story underscores the value of investing in a high-quality anti slip for mats system.

Case Study 2: Marine Vessel Engine Room

"The engine room environment demands extreme durability and oil resistance. Standard floor coverings failed rapidly, creating unsafe conditions. We required a robust anti skid mat capable of handling constant moisture and oil."

Challenge: An international shipping company sought a durable, anti-slip flooring solution for the engine rooms of its fleet, where oil spills, saltwater, and extreme temperatures were common. The existing metal grating proved uncomfortable and still posed slip risks.

Solution: QZSEALS provided specialized, interlocking Drainage Non Slip Mats with enhanced oil and fuel resistance properties. The modular design allowed for easy installation around complex machinery and custom fitting to irregular floor layouts. This included a customized bathtub mat type construction for localized wet zones.

Outcome: The mats significantly improved safety for engineers and crew, providing stable footing even amidst oil and water spills. The anti-fatigue properties were particularly valued during long shifts. The mats exhibited no degradation after two years of continuous exposure to marine elements, confirming their superior durability and contributing to the vessel's operational safety record.

Commitment to Trust: FAQ, Lead Times, Warranty, and Support

Frequently Asked Questions (FAQ)

- Q: Are these mats suitable for outdoor use?

- A: Yes, our Drainage Non Slip Mats are designed with UV stabilizers and robust PVC, making them highly suitable for outdoor applications such as pool surrounds, outdoor walkways, and marine environments. They provide reliable anti slip for mats in all weather conditions.

- Q: How do I clean and maintain the mats?

- A: The open-grid design allows for easy cleaning. Mats can be hosed down with water, scrubbed with mild detergents, or steam cleaned. For deep cleaning, they can be rolled up or lifted to clean the floor underneath. Regular cleaning helps maintain optimal anti-slip performance and hygiene for an anti slip mat.

- Q: Can these mats withstand heavy foot and cart traffic?

- A: Absolutely. Constructed from high-density virgin PVC, our commercial floor mats are engineered for heavy-duty commercial and industrial use, offering excellent resistance to abrasion, tearing, and punctures from constant traffic and equipment. This makes them a durable anti skid mat choice.

- Q: Is installation complicated?

- A: No, installation is straightforward. Mats can be unrolled and laid directly. For interlocking tiles, they simply snap together. Custom cutting can be done with a utility knife for a precise fit. No special tools or adhesives are typically required for our mat for shower or industrial applications.

Lead Time and Fulfillment

QZSEALS maintains efficient production and logistics operations to ensure timely delivery. Standard orders for stock items typically have a lead time of 7-14 business days. Custom orders, depending on complexity and volume, usually range from 3-6 weeks from order confirmation. We work closely with clients to manage project timelines and provide transparent updates for every anti slip mat order.

Warranty Commitments

We stand behind the quality and durability of our products. QZSEALS Drainage Non Slip Mats are backed by a comprehensive 5-year limited warranty against manufacturing defects and premature wear under normal operating conditions. Full warranty details are available upon request and provided with every purchase.

Dedicated Customer Support

Our commitment extends beyond product delivery. QZSEALS offers dedicated technical support and after-sales service. Our team of experts is available to assist with product selection, installation guidance, maintenance best practices, and any post-purchase inquiries. We aim to build lasting partnerships based on trust and superior service for all your anti skid mat needs.

Contact us today to discuss your specific anti slip mat requirements and experience the QZSEALS difference.

References

- ISO. (2015). ISO 9001:2015 Quality management systems — Requirements. International Organization for Standardization.

- ASTM International. (2007). ASTM F1677-07, Standard Test Method for Evaluating Pedestrian Walkway and Roadway Walking Surfaces for Slip Resistance. ASTM International.

- DIN. (2017). DIN 51130: Testing of floor coverings - Determination of the anti-slip properties - Wet-loaded areas - Walking method - Ramp test. Deutsches Institut für Normung.

- Occupational Safety and Health Administration (OSHA). (n.d.). Walking/Working Surfaces Standard. U.S. Department of Labor.

- Grand View Research. (2022). Anti-Slip Coatings Market Size, Share & Trends Analysis Report. (Market data simulation based on industry reports for context)

-

Durable Seal for Oven Door: Perfect Fit, Energy EfficiencyNewsSep.01,2025

-

Durable Silicone Strip Seals: Premium Weather & Door SealingNewsAug.31,2025

-

Premium Seal for Oven Door | Maximize Heat & Energy EfficiencyNewsAug.30,2025

-

Premium Anti Slip Stair Strips: Enhance Safety & Prevent FallsNewsAug.29,2025

-

Clear Corner Protectors: Child Safety for Tables & EdgesNewsAug.28,2025

-

Weather Stripping Door Standard Sizes and Custom CutsNewsAug.12,2025

-

Seal for Oven Door Cleaning and Maintenance TipsNewsAug.12,2025