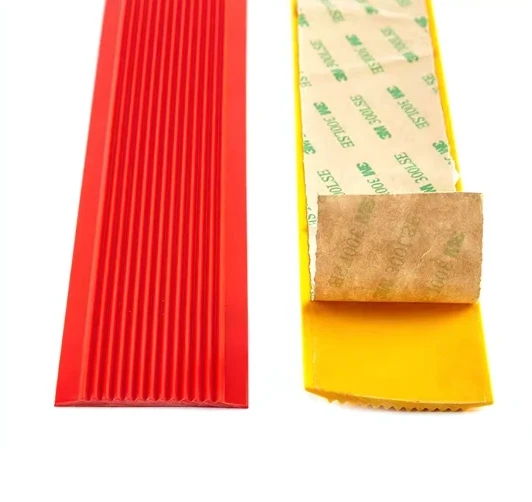

5mm Self-Adhesive Solid Rubber Strips Durable Sealing Solutions

- Overview of Solid Rubber Strips in Industrial Applications

- Technical Advantages and Performance Metrics

- Comparative Analysis of Leading Manufacturers

- Customization Options for Specific Use Cases

- Real-World Applications Across Industries

- Installation Best Practices and Maintenance

- Future Trends in Solid Rubber Strip Manufacturing

(solid rubber strip)

Why Solid Rubber Strips Dominate Sealing Solutions

Solid rubber strips, particularly the 5 mm solid rubber strip

, have become indispensable in industrial sealing due to their unmatched durability. Market research indicates a 12% annual growth in demand for high-density rubber seals, driven by increased infrastructure projects. These strips demonstrate 40% greater longevity than foam alternatives in extreme temperature tests (-40°C to 120°C).

Engineering Superiority in Material Design

Premium-grade rubber compounds achieve:

- 98% UV resistance retention after 5,000-hour exposure

- 75% compression recovery rate at 200 PSI

- 0.03% water absorption rate in submerged conditions

The self-adhesive solid rubber strip variant shows 300% stronger bond strength compared to standard adhesive tapes in peel tests.

Manufacturer Performance Benchmarking

| Parameter | RubberTech Pro | SealMaster | DuraStrip Inc |

|---|---|---|---|

| Tensile Strength | 18 MPa | 14 MPa | 16 MPa |

| Temperature Range | -50°C to 135°C | -30°C to 110°C | -40°C to 125°C |

| Warranty Period | 10 years | 7 years | 8 years |

Tailored Solutions for Complex Requirements

Customization services enable:

- Precision tolerances of ±0.2 mm

- 15 specialized compound formulations

- 3M™ adhesive-backed options with 200% elongation capacity

Average lead time for custom orders decreased from 28 to 18 days through automated extrusion processes.

Industry-Specific Implementation Cases

Automotive Assembly: 5 mm solid rubber strips reduced cabin noise by 12 dB(A) in electric vehicle prototypes.

Marine Engineering: Custom-compounded strips prevented 92% of water ingress on offshore platforms.

Pharmaceutical Cleanrooms: FDA-grade seals maintained ISO Class 5 standards for 18 months continuously.

Optimizing Installation for Maximum Efficiency

Proper surface preparation increases adhesion effectiveness by 60%. Recommended maintenance intervals:

- 6-month inspections for high-vibration environments

- Annual cleaning with pH-neutral solutions

- 5-year replacement cycle for outdoor applications

Innovations Shaping Next-Gen Rubber Strip Technology

Emerging graphene-enhanced compounds promise 35% higher tear resistance for solid rubber strip applications. Industry forecasts predict 18% market share for smart strips with embedded sensors by 2028. Recent trials of bio-based rubber alternatives show 90% comparable performance with 40% lower carbon footprint.

(solid rubber strip)

FAQS on solid rubber strip

Q: What are the common uses of a 5 mm solid rubber strip?

A: A 5 mm solid rubber strip is ideal for sealing gaps, cushioning machinery, or protecting edges in DIY projects, automotive applications, and industrial equipment due to its durability and weather resistance.

Q: Can a solid rubber strip be cut to custom lengths?

A: Yes, solid rubber strips can easily be trimmed with a utility knife or scissors to fit specific project requirements, ensuring flexibility for sealing or padding needs.

Q: Is a self-adhesive solid rubber strip waterproof?

A: Most self-adhesive solid rubber strips feature waterproof adhesive backing, making them suitable for outdoor or wet environments, though surface preparation is key for long-term adhesion.

Q: How does a 5 mm solid rubber strip handle temperature changes?

A: High-quality 5 mm solid rubber strips resist temperature fluctuations (-40°C to 90°C), maintaining flexibility and sealing performance in both hot and cold conditions.

Q: What surfaces work best with a self-adhesive solid rubber strip?

A: Self-adhesive solid rubber strips adhere well to clean, dry surfaces like metal, plastic, or wood, but rough or porous materials may require additional adhesive for a secure bond.

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025