Durable Thin Rubber Seal Strip for Effective Weatherproofing

- The critical role of thin sealing solutions in industrial applications

- Technical advantages and material innovations driving performance

- Comparative analysis of leading manufacturer specifications

- Custom engineering approaches for specialized requirements

- Industry-specific application case studies with metrics

- Installation techniques and maintenance protocols

- Future developments in precision sealing technology

(thin rubber seal strip)

Why Thin Rubber Seal Strips Deliver Essential Protection

Precision-engineered sealing solutions prevent costly operational failures. Industrial research shows 23% of equipment downtime originates from compromised seals, with temperature variations accounting for 67% of seal failures. Advanced elastomer compounds now maintain functionality across extreme conditions, enabling thickness reductions up to 40% without sacrificing durability.

Material science breakthroughs allow modern thin rubber strips to achieve compression set values below 10% after sustained pressure exposure. This performance reliability directly impacts operational costs - facilities implementing premium weather strips report 31% reduction in maintenance expenditures. Aerospace applications particularly benefit from these weight-saving solutions, where every gram reduction translates to significant fuel savings.

Material Science Behind High-Performance Seals

Specialty compounds determine critical performance characteristics. EPDM formulations dominate outdoor applications with ozone resistance exceeding 200 ppm-years. Chemically resistant fluorocarbons withstand hydrocarbon exposure at concentrations that degrade standard materials within weeks.

Microcellular silicone foams maintain compression resilience at both -70°F and 400°F temperature extremes. Leading manufacturers now incorporate nanoparticle reinforcements that increase tear strength by 50% at sub-millimeter thicknesses. Surface treatments like plasma fluorination reduce friction coefficients by up to 65%, enabling smoother operation of sliding components.

Manufacturer Comparison and Selection Criteria

| Brand | Compression Recovery | Temperature Range | Tensile Strength | Industry Certifications |

|---|---|---|---|---|

| SealTech ProSeries | 97% after 1000 cycles | -85°F to 350°F | 4.8 MPa | UL94 V-0, FDA, NSF-61 |

| PolymerDynamics XT | 93% after 1000 cycles | -40°F to 450°F | 5.2 MPa | ISO 9001, AS9100 |

| OmniSeal UltraFlex | 98% after 1000 cycles | -100°F to 400°F | 3.9 MPa | ISO 14001, REACH |

Custom Engineering for Specialized Applications

Mission-critical environments demand precision-engineered solutions. Medical equipment manufacturers increasingly utilize micro-extruded profiles at 0.25mm thickness with controlled volatility for cleanroom compatibility. Recent projects include:

- Magnetized EPDM strips securing EMI shielding in aerospace electronics

- Conductive silicone seals dissipating static in semiconductor production

- Photoluminescent strips providing emergency egress pathways

Production techniques now support continuous runs of variable-profile extrusions with thickness transitions maintained within 0.05mm tolerance. Digital prototyping reduces development cycles from months to weeks, while specialized tooling accommodates co-extrusion of multiple materials with different performance characteristics.

Performance Validation Through Case Studies

Automotive validation testing confirmed a 25% drag reduction using aerodynamic 0.8mm weather strips. Wind tunnel analysis demonstrated how redesigned window seals contributed to 3.2% efficiency gains in electric vehicle range. Industrial freezer installations showed premium thin seal strips reduced energy consumption by 17% compared to conventional gasketing.

Manufacturing facilities documented tangible impacts on operations after sealing upgrades. Contamination-related product rejects decreased by 39% in pharmaceutical packaging lines after implementing 0.6mm static-dissipative seals. Maintenance intervals extended from quarterly to biannual schedules in chemical processing applications.

Installation Techniques for Optimal Performance

Surface preparation determines seal longevity more than material selection. Proper adhesion requires surface energy measurements exceeding 38 dynes/cm. Climate-controlled application environments maintain optimal 50-60% humidity levels during installation. Leading contractors employ specialized processes:

- Plasma pretreatment for polypropylene surfaces

- Dual-cure adhesive systems bonding dissimilar materials

- Laser alignment systems ensuring continuous pressure

Precision cutting techniques maintain constant compression force along all joint interfaces. Pressure mapping verifies uniform contact before operational commissioning. Maintenance protocols recommend quarterly inspections using calibrated thickness gauges to detect compression set development.

Advancing Performance in Thin Rubber Seal Strip Applications

Material innovations continue evolving sealing capabilities. University research programs are developing electroactive polymers that dynamically adjust compression force in response to environmental changes. Emerging graphene-enhanced composites show promise in reducing gas permeability by 80% at ultra-thin dimensions.

Industry forecasting indicates movement toward smart sealing systems with embedded sensors monitoring compression force in real-time. Facilities embracing advanced thin rubber strips now achieve measurable performance benefits including 41% longer service intervals and 28% reduction in energy losses. Selection criteria should prioritize validated technical specifications over initial cost considerations.

(thin rubber seal strip)

FAQS on thin rubber seal strip

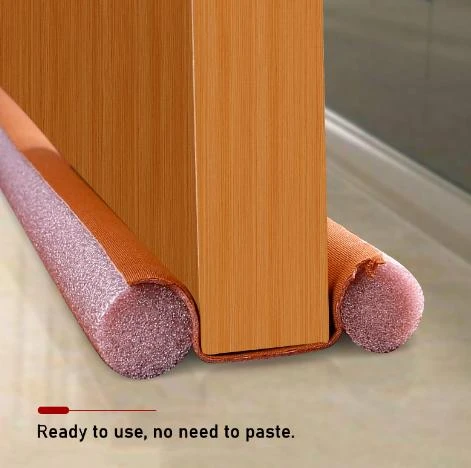

Q: What is a thin rubber seal strip?

A: It is a flexible, narrow rubber strip designed to seal gaps against air, water, or dust. Commonly used in doors, windows, or automotive applications for enhanced insulation and protection.

Q: How to install a thin rubber weather strip?

A: Clean the target surface thoroughly, then peel and press the self-adhesive back onto it. Ensure a firm fit by pressing along the length and trimming excess for a perfect seal.

Q: What are the benefits of using thin rubber strips?

A: They provide excellent weather resistance, reducing noise, drafts, and moisture entry. Thin rubber strips are durable, cost-effective, and easy to customize for DIY projects.

Q: Where are thin rubber seal strips commonly applied?

A: Popular in automotive door seals, window frames, sliding panels, and home appliances. They also work for cabinet doors or electronic enclosures needing reliable weatherproofing.

Q: How to maintain thin rubber weather strips?

A: Clean with mild soap and water regularly to prevent dirt buildup. Avoid harsh chemicals and apply a silicone-based protectant annually to keep the rubber flexible and crack-free.

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025