Durable Silicone Strip Seal for Door Weather Stripping

In the modern industrial and architectural landscape, achieving a perfect seal is paramount for efficiency, safety, and longevity. The silicone strip seal has emerged as a superior solution, outperforming traditional materials across a vast spectrum of applications. This guide provides an in-depth exploration of silicone sealing technology, covering everything from industry trends and technical specifications to real-world case studies, establishing why this versatile material is the gold standard for sealing challenges.

Industry Trends: The Rising Demand for High-Performance Sealing

The global market for elastomers and sealing solutions is experiencing a significant shift towards high-performance materials. Environmental regulations, the push for energy efficiency, and increasingly stringent industrial standards are driving this change. The silicone rubber market, valued at approximately USD 17.5 billion in 2022, is projected to grow at a CAGR of over 5.5% through 2030. This growth is largely fueled by the unique properties of silicone that meet the demands of advanced sectors like automotive (especially EVs), electronics, healthcare, and renewable energy.

For applications such as wood door weather stripping and industrial oven gaskets, consumers and businesses are no longer satisfied with basic rubber seals that degrade quickly. They demand solutions that offer long-term stability, resistance to extreme temperatures, and protection against environmental factors. This is where the silicone door seal strip excels, offering a "fit-and-forget" solution that maintains its integrity for years, ensuring consistent performance and reducing maintenance costs.

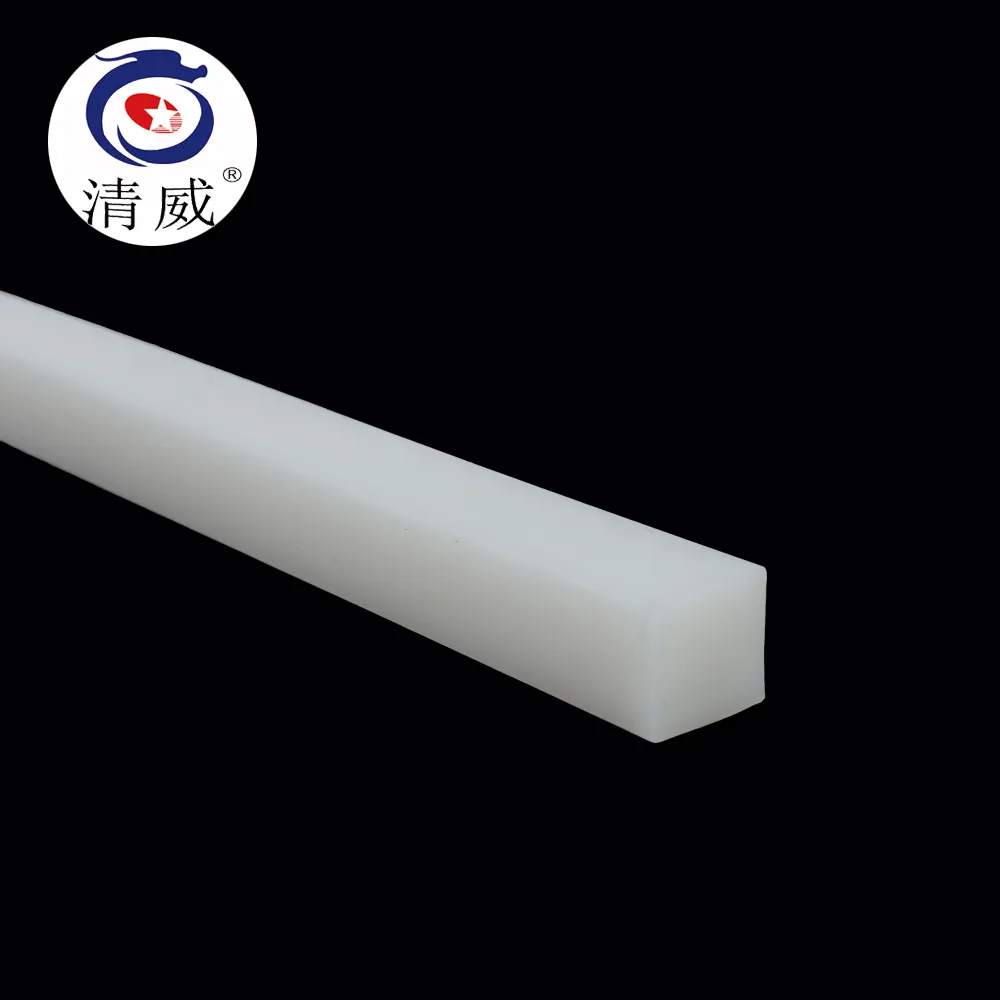

A collection of custom-profiled silicone strip seals, showcasing their versatility for different applications.

Technical Parameters: Understanding What Makes Silicone Superior

A silicone strip seal is not just a piece of rubber; it's an engineered component with specific properties tailored for performance. The key to its effectiveness lies in its chemical structure, based on a silicon-oxygen (Si-O) backbone, which is far more stable than the carbon-carbon (C-C) backbone of organic rubbers. This results in outstanding thermal stability and resistance to ozone and UV radiation. Below is a comprehensive table comparing common types of sealing strips.

| Parameter | Silicone Rubber Seal | EPDM Rubber Seal | Neoprene (CR) Rubber Seal | Nitrile (NBR) Rubber Seal |

|---|---|---|---|---|

| Temperature Range | -60°C to 230°C (up to 300°C with special grades) | -40°C to 120°C | -35°C to 100°C | -30°C to 110°C |

| UV & Ozone Resistance | Excellent | Excellent | Good | Poor |

| Hardness (Shore A) | 20 - 80 | 40 - 90 | 40 - 90 | 40 - 90 |

| Oil & Fuel Resistance | Fair (Special fluorosilicone grades are excellent) | Poor | Good | Excellent |

| Compression Set | Excellent (low) | Good | Good | Fair to Good |

| Weathering | Excellent | Excellent | Good | Poor |

| Typical Application | High-temp ovens, food-grade seals, outdoor fixtures, wood door weather stripping | Automotive seals, roofing membranes | Hoses, gaskets, weather stripping | Fuel hoses, oil seals, O-rings |

Featured Product: Gap Solid Silicone Rubber Strip Anti Oil High Temp

Our premier product, the Gap Solid Silicone Rubber Strip Anti Oil High Temp, is a testament to advanced material science. Engineered for the most demanding environments, this silicone strip seal offers exceptional resistance to high temperatures and oils, making it ideal for industrial machinery, automotive engines, and commercial kitchens. It serves as a perfect door bottom seal rubber strip in high-traffic, temperature-variable environments.

Compliance Standards: ISO 9001, FDA 21 CFR 177.2600, RoHS Compliant.

The Manufacturing Journey of a Silicone Strip Seal: Precision and Quality Control

The creation of a high-quality silicone strip seal is a multi-stage process governed by strict quality controls compliant with standards like ISO 9001. Understanding this process reveals the expertise and technology required to produce a reliable product.

1. Raw Material Compounding

High-purity silicone gum (VMQ) is mixed with fillers, vulcanizing agents, and specific additives (e.g., colorants, heat stabilizers) in a two-roll mill or internal mixer.

2. Extrusion

The compounded material is fed into an extruder. A screw pushes the heated, softened silicone through a custom-designed die to create the desired profile (square, round, D-shape, etc.).

3. Vulcanization (Curing)

The extruded profile passes through a high-temperature curing oven or a continuous vulcanization (CV) line (e.g., using microwaves or hot air) to cross-link the polymer chains, giving it its solid, elastic properties.

4. Post-Curing

The seal is baked in an oven for several hours to remove any volatile byproducts from the vulcanization process and to stabilize its physical properties. This step is critical for FDA-grade products.

5. Quality Inspection & Cutting

The continuous strip is inspected for dimensional accuracy, surface defects, and hardness. It is then precision-cut to the required lengths.

6. Packaging & Shipping

Finished strips are coiled, packaged to protect from contamination, and prepared for shipment to the customer.

This meticulous manufacturing process ensures that every silicone weather stripping we produce meets exacting standards for dimensional tolerance, material purity, and performance longevity. Our commitment to quality is validated by our ISO 9001:2015 certification, ensuring traceability and consistency in every batch.

High-quality silicone door seal strip ensures a perfect, long-lasting seal for premium wooden doors.

Technical Advantages & Performance Comparison

The superiority of a silicone strip seal over conventional elastomers is not just anecdotal; it's backed by measurable data. The following chart illustrates the performance advantages of our silicone products compared to standard EPDM, a common material for weather stripping.

Performance Comparison: Silicone vs. EPDM Rubber

*The chart represents relative performance scores where a higher bar indicates superior capability. Silicone (dark blue and light blue bars) consistently outperforms EPDM in key areas for long-term sealing.

- Extreme Temperature Resistance: As shown, silicone maintains its flexibility and sealing properties from as low as -60°C to over 230°C. This makes it the only viable choice for applications with wide temperature swings, such as industrial freezers and commercial baking ovens.

- Unmatched Durability: The exceptional resistance to UV light and ozone means a silicone strip seal installed outdoors will not crack, harden, or become brittle over time, unlike many organic rubbers. This is critical for applications like wood door weather stripping and window seals.

- Low Compression Set: This technical term refers to a material's ability to return to its original thickness after being compressed for a long period. Silicone has an extremely low compression set, meaning it won't permanently flatten over time. This ensures a continuous, effective seal throughout its service life, preventing leaks and energy loss.

- Inert and Hygienic: High-purity silicone is non-toxic, odorless, and tasteless. It does not support microbiological growth, making it the material of choice for the food, beverage, and medical industries. Our products can be certified to meet FDA and LFGB standards.

The resilience of a silicone door bottom seal rubber strip prevents drafts, dust, and pests.

Application Scenarios: Where Silicone Seals Make a Difference

The versatility of the silicone strip seal allows it to be deployed across a multitude of industries. Its unique combination of properties solves sealing challenges where other materials fail.

Application Breakdown by Industry

- Industrial Machinery (40%)

- Construction & Architecture (30%)

- Food & Beverage Processing (20%)

- Automotive & Electronics (10%)

- Industrial Machinery & Petrochemical: Sealing high-temperature enclosures, access panels on processing equipment, and protecting sensitive electronics from dust and moisture. Its oil resistance is vital for hydraulic systems and engine compartments.

- Construction & Architecture: Used as premium silicone weather stripping for windows and doors. The wood door weather stripping market increasingly favors silicone for high-end projects due to its longevity and aesthetic options (it can be color-matched). It creates an airtight seal, significantly improving a building's energy efficiency (HVAC savings).

- Food & Beverage Processing: Sealing oven doors, fermentation tanks, and processing lines. The ability to be FDA compliant and withstand high-temperature steam cleaning (CIP/SIP cycles) is non-negotiable in this sector.

- Automotive & Electronics: Gasketing for EV battery enclosures, sealing automotive lighting, and protecting sensitive electronic control units (ECUs) from vibration and environmental ingress.

Rolls of high-grade silicone strip seal ready for customization into various lengths and profiles.

Customization: Your Sealing Solution, Your Way

We understand that one size does not fit all. Standard profiles are just the beginning. Our expertise lies in providing fully customized silicone strip seal solutions tailored to your specific application. Our engineering team works directly with clients to develop the perfect seal based on:

- Dimensions & Profile: From simple squares and circles to complex, multi-lumen geometric profiles, we can create the exact shape you need via custom extrusion dies.

- Hardness (Durometer): We can formulate compounds from a soft, sponge-like 20 Shore A to a hard, rigid 80 Shore A.

- Color: While translucent, white, and black are standard, we can match virtually any RAL color for aesthetic or color-coding purposes.

- Specialty Formulations: Need enhanced properties? We offer fluorosilicone for superior chemical/fuel resistance, conductive silicone for EMI/RFI shielding, and steam-resistant grades for autoclave applications.

- Adhesive Backing: For easy installation, we can apply high-temperature pressure-sensitive adhesive (PSA) to one side of your silicone door seal strip.

Case Study: Energy Savings in a Commercial Bakery

"We were losing significant heat from our rack oven doors, leading to inconsistent baking and high energy bills. The original seals would harden and crack within six months. After consulting with the engineering team, we switched to their custom high-temperature silicone strip seal. The new seals have been in place for over two years with no degradation. Our energy consumption for the ovens dropped by nearly 15%, and our product consistency has improved dramatically. The investment paid for itself in less than a year."

Building Trust: Our Commitment to Quality and Service (E-E-A-T)

In a market flooded with options, choosing the right supplier is critical. Our commitment to Google's E-E-A-T (Experience, Expertise, Authoritativeness, Trustworthiness) principles is at the core of our business.

Expertise & Experience

With over 15 years in the sealing industry, our team possesses deep material science knowledge. We don't just sell products; we solve sealing problems.

Authoritativeness

Our operations are ISO 9001:2015 certified, and our products meet stringent international standards like FDA, RoHS, and REACH. We are a trusted supplier to leading firms in the industrial and construction sectors.

Trustworthiness

We believe in transparency. Clear communication, reliable delivery schedules, comprehensive warranties, and responsive customer support are our promises to you.

This specialized silicone strip seal is engineered to withstand the extreme heat of industrial applications.

Frequently Asked Questions (FAQ)

Durometer, measured on the Shore A scale for flexible rubbers, indicates the material's hardness. A lower number (e.g., 30A) is softer and more compressible, ideal for sealing uneven surfaces with low closure force. A higher number (e.g., 70A) is harder and more durable, suitable for high-pressure applications or where abrasion resistance is needed. For most silicone weather stripping applications, a durometer of 40A to 60A is common.

Absolutely. We offer specific grades of silicone strip seal that are manufactured using FDA-compliant ingredients listed in 21 CFR 177.2600. These seals undergo a post-curing process to ensure no harmful substances can leach into food, making them perfectly safe for use in commercial kitchens, food processing plants, and dairy applications.

The terms are often used interchangeably, but "silicone strip seal" is a broader industrial term for any silicone profile used for sealing. "Silicone weather stripping" specifically refers to seals used in architectural applications (windows, doors) to block out weather elements like rain, wind, and drafts. A product like a wood door weather stripping is a type of silicone strip seal.

For best results, the surface must be clean, dry, and free of any oils or dust. Use an isopropyl alcohol wipe to prepare the surface. Peel back a small section of the adhesive liner, align the strip, and press it firmly into place. Continue to peel the liner as you apply the strip, applying even pressure along the entire length. Allow the adhesive to cure for 24 hours before exposing it to significant stress or moisture.

When used within its specified temperature and chemical resistance range, a silicone door bottom seal rubber strip can last for 20 years or more. Its excellent resistance to UV, ozone, and environmental aging means it will not become brittle or crack like EPDM or vinyl seals, providing a much longer service life and better long-term value.

Lead times vary based on complexity and volume. For custom extrusion dies, initial tooling can take 2-3 weeks. Once the tool is approved, production runs for custom silicone strip seal profiles typically have a lead time of 2-4 weeks. We provide a detailed project timeline with every custom quote.

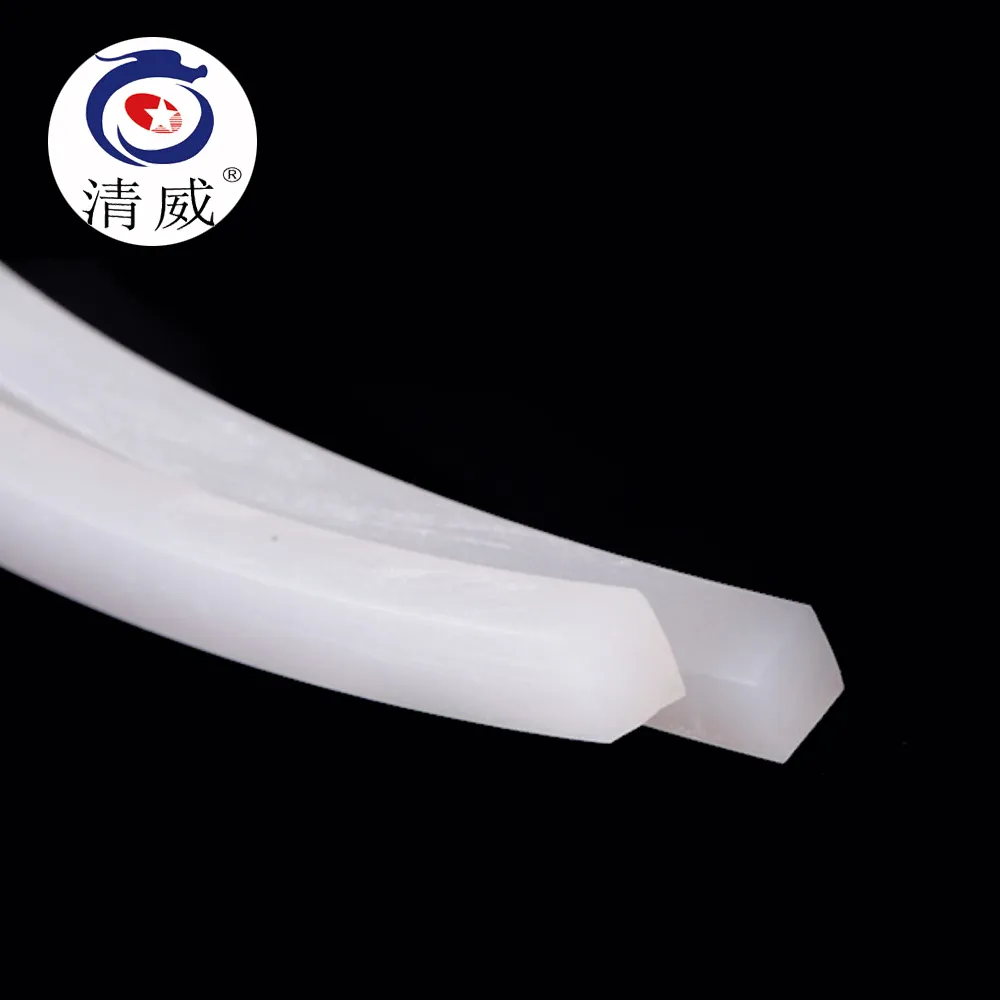

From simple squares to complex custom designs, the right silicone strip seal profile is key to performance.

Conclusion & Further Reading: The silicone strip seal stands as a premier material for modern sealing solutions, offering an unparalleled combination of thermal stability, durability, and safety. Its adaptability through customization makes it the optimal choice for engineers and designers aiming for long-term reliability and efficiency. For more technical information on silicone elastomer properties, we recommend reviewing academic resources and industry publications.

Reference: "Silicone Rubber Chemistry and Technology" – An in-depth discussion on the material properties and applications of silicone elastomers. Found in forums and libraries such as the ACS Publications or detailed discussions on platforms like the Rubber & Plastics News (https://www.rubbernews.com/).

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025