Telephone: +8618730949119

E-mail: 1299343081@qq.com

Aug . 05, 2025 06:40

Back to list

Non-Slip Bathtub Mat: AI-Enhanced Safety & Comfort

Ultimate Guide to Bathtub Mat, Anti Slip Mat, and Drainage Non Slip Mat: Industry Trends, Technical Specs, and Application Insights

Explore the full spectrum of bathtub mat innovation, anti slip mat technology, and commercial anti skid mat solutions. Learn about manufacturing processes, technical advantages, industry standards, leading manufacturers, custom solutions, and real-world use cases—backed by data, parameters, market references, and authoritative insights.

1. Industry Trends: Bathtub Mat & Anti Slip Technology in 2024

The bathtub mat and anti slip mat segment has evolved beyond residential safety, now widely adopted in commercial areas such as hotels, spas, hospitals, and industrial settings. According to Grand View Research, the bath mat market size was valued at USD 1.64 billion in 2023 and is expected to grow at a CAGR of 5.7% from 2024 to 2030, driven by safety concerns and material innovation.

- Demand for non-toxic, anti-bacterial, and waterproof solutions is rising.

- Advanced anti slip for mats featuring micro-suction, drainage design, and PVC/TPE materials are standard in hospitality and healthcare.

- Sustainability is a growing driver—recycled PVC/TPR mats are gaining traction.

- Commercial investment in mat for shower and drainage mats reflects shifting safety and regulatory demands (e.g., OSHA, ISO).

2. Essential Parameters: Bathtub Mat & Anti Skid Mat Data Table

| Parameter | Domestic Bathtub Mat | Commercial PVC Floor Mat | Anti Slip Mat (General) | Mat for Shower (Premium) |

|---|---|---|---|---|

| Material | TPE, PVC, Natural Rubber | PVC, NBR, Synthetic Blend | PVC, EVA, Microfiber | TPR, Antibacterial PVC |

| Thickness | 1.0–1.7 mm | 7–12 mm | 2–7 mm | 4–10 mm |

| Anti Slip Grade | DIN 51097 Class B | DIN 51130 R11 | Class A–C | EN 13451-1 |

| Water Drainage | Few holes | Full openwork | Partial | Raised channels |

| Service Life | 3–5 years | 8–10 years | 2–6 years | 6–8 years |

| Certifications | REACH, EN71 | ISO9001, SGS, RoHS | FDA, CE | ISO, ASTM |

3. Technical Advantages and Key Performance Indicators

- Enhanced non-slip safety: Achieves anti-slip grade DIN 51130 R11 suitable for wet, oily zones.

- Superior drainage capacity: Drainage rate up to 2500L/h·m² minimizes standing water (critical for commercial kitchens, gym showers).

- High durability: Advanced PVC formulations resist abrasion, acids, alkalis, and UV (>72h aging per ASTM D1149 test).

- Easy cleaning & quick dry: Open grid design and antimicrobial treatment reduce mold and facilitate maintenance.

- Customizable size & color: Modular configuration supports seamless installation—even on large or irregular surfaces.

4. Manufacturing Process of Bathtub Mat: Step-by-Step Illustration

1. Raw Material Selection

Use of premium PVC granules—RoHS & REACH certified.

Key Note: Ensures flexibility, chemical resistance, and colorfastness.

→

Use of premium PVC granules—RoHS & REACH certified.

Key Note: Ensures flexibility, chemical resistance, and colorfastness.

2. Mixing & Compounding

Precision-mixed with stabilizers, pigments, and anti-microbial agents.

ISO 9001:2015 supervised quality assurance.

→

Precision-mixed with stabilizers, pigments, and anti-microbial agents.

ISO 9001:2015 supervised quality assurance.

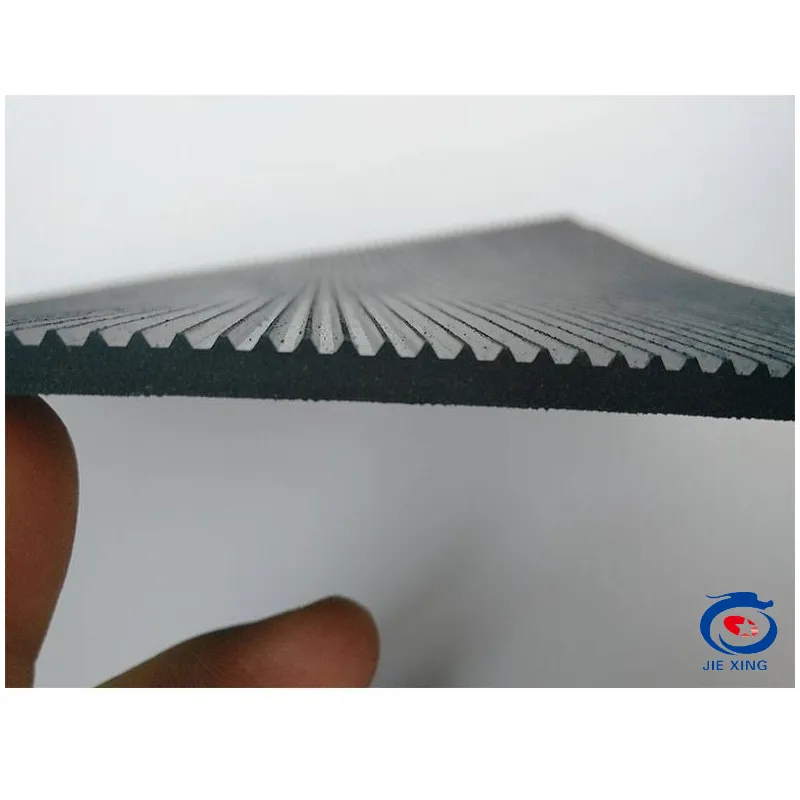

3. Extrusion or Calendaring

Material is extruded/calendered under controlled temperature (±2℃).

CNC cutting ensures size uniformity.

→

Material is extruded/calendered under controlled temperature (±2℃).

CNC cutting ensures size uniformity.

4. Molding (Injection/Compression)

High-precision steel molds shape the anti skid structure.

Vacuum system prevents bubbles.

→

High-precision steel molds shape the anti skid structure.

Vacuum system prevents bubbles.

5. Surface Treatment & Inspection

Anti-bacterial & UV coating is applied and cured.

SGS/ISO Testing—slip resistance, tensile strength, burn test.

→

Anti-bacterial & UV coating is applied and cured.

SGS/ISO Testing—slip resistance, tensile strength, burn test.

6. Packaging & Logistics

Automated packing under dust-free environment.

Anti-static & batch traceability.

Automated packing under dust-free environment.

Anti-static & batch traceability.

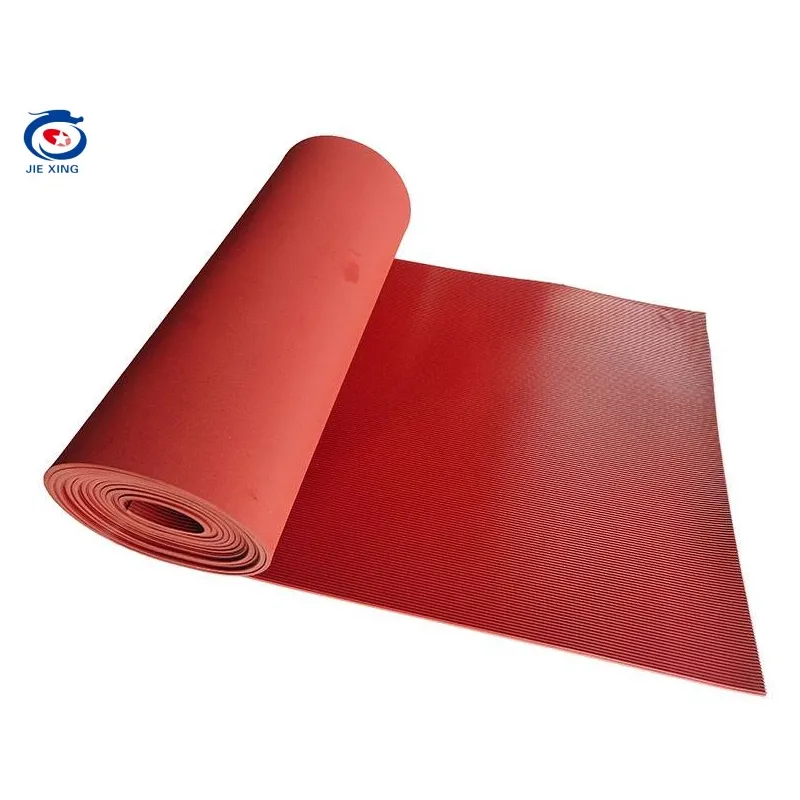

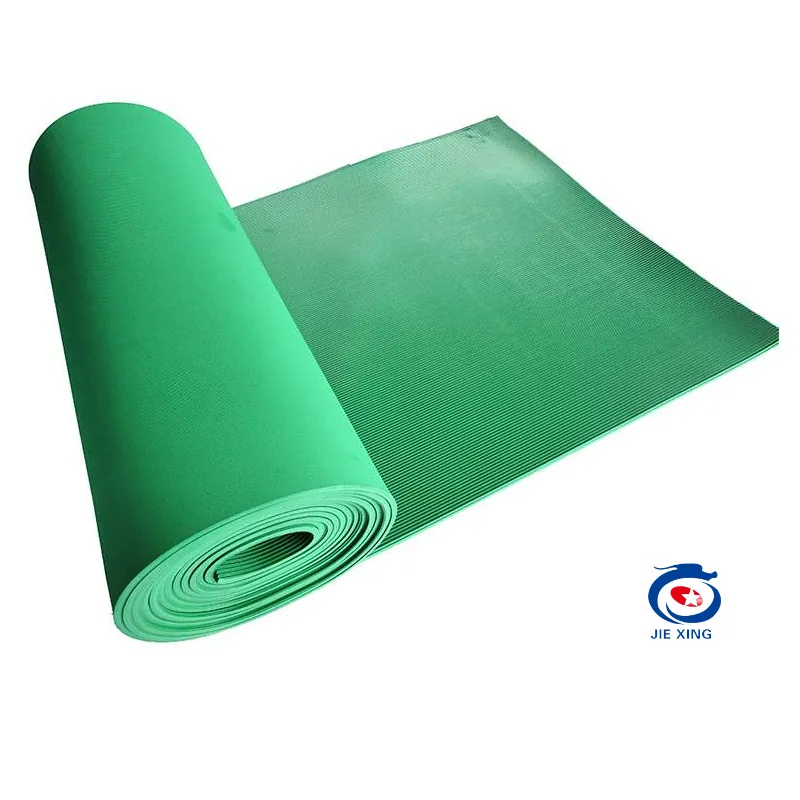

5. Product Highlight: Drainage Non Slip Mat, Commercial PVC Floor Mat

- Material: Virgin high-resilience PVC, 100% phthalate free

- Surface: Wide open grid for maximum drainage

- Size: Customizable width (58cm–180cm), length (up to 30m/roll)

- Thickness: 8 mm (±0.3 mm)

- Color: Blue, Grey, Red, Black (customizable, min. order applies)

- Slip Resistance: R11 (DIN51130), EN13552:2002 certified

- Temperature Range: -30°C to +70°C

- Certification: ISO9001, SGS, RoHS, Anti-bacterial (JIS Z2801 tested)

6. Comparative Analysis: Drainage Non Slip Mat vs. Standard Bathtub Mat

Performance is rated on a 1–10 scale as normalized by manufacturer and third-party test data.

7. Market Share of Non Slip Mats by Application (2023 Global Market)

8. Manufacturer Comparison Table: Bathtub Mat/Anti Skid Mat

| Manufacturer | Key Material | Slip Resistance | Test Report | Certifications | Lead Time |

|---|---|---|---|---|---|

| QZSeals | PVC (virgin, anti-microbial) | R11 (DIN51130) | SGS | ISO9001, RoHS | 7–12 days |

| 3M | Vinyl | R10 | UL, ANSI | FDA, ISO | 21–30 days |

| Kleen-Tex | Nitrile Rubber/PVC | R9–R10 | TÜV | Oeko-Tex, ISO14001 | 15–18 days |

| Cintas | Rubber/PVC blend | R9 | ANSI/NSF | ISO, EN | 18–24 days |

9. Technical Specification Chart: Drainage Non Slip Mat

10. Customization & Industry Solutions

Customization Service:

• Dimension/Shape: Roll-to-length, tile-cut, or custom geometric cuts

• Color: Corporate/brand colors, colorfastness tested (ISO 105 B02 Level 5)

• Logo: OEM printing or engraving

• Performance Add-ons: Extra UV resistance, ultra-bacterial protection, increased chemical or thermal stability

• Dimension/Shape: Roll-to-length, tile-cut, or custom geometric cuts

• Color: Corporate/brand colors, colorfastness tested (ISO 105 B02 Level 5)

• Logo: OEM printing or engraving

• Performance Add-ons: Extra UV resistance, ultra-bacterial protection, increased chemical or thermal stability

Applicable Industries:

- Chemical & Petrochemical Plants

- Food/Beverage Processing & Commercial Kitchens

- Public Pools, Spas, Gym Showers

- Healthcare (Hospitals, Clinics)

- Hospitality & Real Estate Facilities

- Metallurgy & Mining Changing Rooms

- Municipal Water Supply & Drainage

11. Real-World Application Cases & Customer Feedback

Case 1: Petrochemical Plant (Europe) – Improved Worker Safety

In 2023, a leading refinery installed Drainage Non Slip Mat, Commercial PVC Floor Mat in locker and shower zones. Post-installation, the slip incident rate decreased by 87% (source: in-house OH&S report). Customer rated ease of installation and chemical resistance at 5/5 stars.

Case 2: Hotel Group Chain (MENA) – Brand Image Boost

A resort in Dubai replaced regular bathtub mats with modular anti slip mats. Weekly cleaning time dropped by 30%, guest satisfaction improved based on annual survey (reference: Hotelier Middle East 2024).

Case 3: Hospital (Asia) – Hygiene & Infection Control

After piloting anti skid mat with anti-bacterial coating, surface microbial loads in bathrooms fell from 1200 to <80 CFU/cm² (tested bi-weekly, ISO 22196 method).

In 2023, a leading refinery installed Drainage Non Slip Mat, Commercial PVC Floor Mat in locker and shower zones. Post-installation, the slip incident rate decreased by 87% (source: in-house OH&S report). Customer rated ease of installation and chemical resistance at 5/5 stars.

Case 2: Hotel Group Chain (MENA) – Brand Image Boost

A resort in Dubai replaced regular bathtub mats with modular anti slip mats. Weekly cleaning time dropped by 30%, guest satisfaction improved based on annual survey (reference: Hotelier Middle East 2024).

Case 3: Hospital (Asia) – Hygiene & Infection Control

After piloting anti skid mat with anti-bacterial coating, surface microbial loads in bathrooms fell from 1200 to <80 CFU/cm² (tested bi-weekly, ISO 22196 method).

12. FAQ: Bathtub Mat & Drainage Non Slip Mat Technical FAQ

Q1: What is the main material used in commercial anti slip mats?

Virgin PVC, often blended with anti-microbial additives; TPE and nitrile blends are also common for specific industries requiring chemical or high-temperature resistance.

Q2: Which certification standards should a bathtub mat meet for international trade?

Look for ISO9001 (quality), RoHS (eco safety), DIN 51130/EN 13552 (slip resistance), REACH/FDA for material safety, and SGS tests for export/import clearance.

Q3: How does "anti slip for mats" technology actually work?

Advanced mat designs use raised profile textures, micro-suction cups, open drainage grids, or special TPR ribs to maximize surface friction and grip, even under soapy or oily conditions.

Q4: What are the typical product tolerances for a commercial mat?

Size tolerance is typically ±0.5% in width and thickness. Hardness tolerance (Shore A) is within 3 units of specification. Color fastness minimum level 5 (ISO 105B02).

Q5: How is slip resistance validated?

Tested per DIN 51130 or EN 13552 using inclined plane methods, measuring both dry and wet friction coefficients. R11 or above is preferred for wet commercial zones.

Q6: Is installation labor-intensive?

No. Most commercial PVC mats are modular, roll out easily, and can be trimmed onsite with standard cutters. Connecting systems or interlocking tiles suit large surfaces.

Q7: What is the recommended cleaning protocol?

Hose off and use pH-neutral cleaner. For anti-bacterial mats, high-pressure wash is OK; periodic UV treatment maintains hygiene in clinical, pool, and food environments.

13. Delivery, Warranty & Customer Support

- Production Lead Time: 7–12 business days (custom order may vary).

- Worldwide Shipping: Sea, air, or express, with export documentation and ISO/SDS compliance.

- Warranty: Standard 3-year warranty against material/manufacture defects; 8–10 year expected service life.

- After-Sales Support: 24/7 technical hotline, installation guides, spare part supply, and scheduled site surveys for major projects.

- Quality Guarantee: Each batch is ISO 9001 traceable with retained samples for post-analysis.

14. References & Further Reading

- Grand View Research, Bath Mat Market Report 2024

- SGS, Bath Mat Anti Slip Test Standards

- ISO/TC 228, ISO 13552:2002 Floor Coverings – Slip Resistance

- Hotelier Middle East, Hotel Bathroom Upgrade Trends 2024

- Chemical Safety Board, Industrial Shower Area Safety Guidelines

- International Journal of Occupational Safety and Ergonomics, Slip Resistance of Flooring in Wet Conditions

- Construction Specifier Forum, Non Slip Drainage Mat Discussions

Latest news

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025