Durable Silicone Strip Seal for Doors & Windows | Weatherproofing

In the intricate world of modern engineering and construction, the integrity of a seal can be the defining factor for performance, efficiency, and longevity. Among the myriad of sealing solutions available, the silicone strip seal stands out as a superior choice, renowned for its unparalleled properties. This comprehensive guide delves into the essence of silicone sealing technology, exploring its industrial significance, technical specifications, and diverse applications, with a specific focus on the Gap Solid Silicone Rubber Strip Anti Oil High Temp product from QZSEALS.

Industry Trends and the Evolution of Sealing Technology

The demand for high-performance sealing materials has surged across various sectors, driven by stricter environmental regulations, the push for energy efficiency, and the need for enhanced durability in extreme conditions. Traditional sealing materials often fall short when confronted with challenges such as wide temperature fluctuations, exposure to harsh chemicals, UV radiation, and ozone. This is where advanced elastomers, particularly silicone rubber, have carved out a dominant niche, transforming industries from automotive to construction.

Recent industry reports indicate a steady growth in the global industrial seals market, with silicone seals projected to be a significant contributor due to their superior performance characteristics. According to a market analysis by Grand View Research, the global industrial seals market size was valued at USD 13.9 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 4.5% from 2023 to 2030. This growth is largely driven by escalating demand from critical sectors such as oil & gas, chemical processing, pharmaceuticals, and the burgeoning electric vehicle market. The unique properties of silicone, such as its excellent thermal stability, chemical inertness, flexibility, and resistance to environmental degradation, position it as an ideal material for future-proof sealing solutions that minimize leaks and maximize operational uptime.

Beyond heavy industrial applications, the residential and commercial sectors are increasingly adopting solutions like silicone weather stripping and wood door weather stripping to improve building insulation and reduce energy consumption. As awareness about thermal efficiency and indoor air quality grows, the adoption of high-performance seals, including the silicone door seal strip and door bottom seal rubber strip, becomes crucial. These applications directly contribute to a reduction in heating and cooling costs, aligning with global sustainability goals and making silicone a vital component in green building practices.

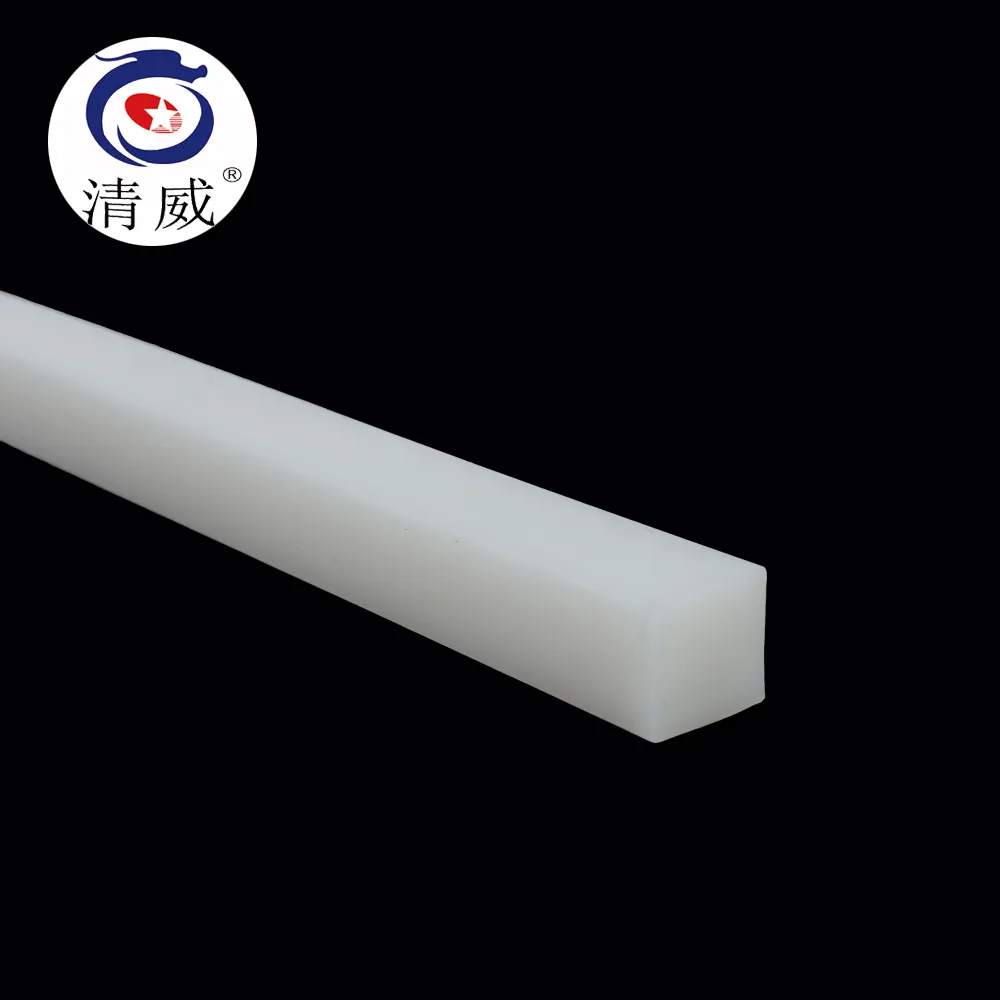

Advanced silicone strip seal applications showcasing durability in diverse industrial environments.

Technical Parameters and Properties of Silicone Strip Seal

The effectiveness of a silicone strip seal is directly attributable to its remarkable material properties, which set it apart from conventional elastomers. Silicone rubber, a synthetic elastomer, fundamentally differs from organic rubbers in its molecular backbone; instead of carbon-carbon chains, it features a silicon-oxygen (siloxane) backbone. This unique chemical structure imparts superior thermal stability, UV resistance, and ozone resistance, making it an ideal choice for challenging applications.

Key Technical Specifications for High-Performance Silicone Strip Seals:

| Property | Typical Range for High-Performance Silicone | Unit | Relevance/Significance |

|---|---|---|---|

| Temperature Resistance (Continuous) | -60°C to +230°C (up to +300°C for special HTV grades) | °C | Crucial for maintaining flexibility and sealing integrity in extreme high or low temperatures (e.g., cryogenic systems, industrial ovens, automotive engines). Prevents material degradation and hardening/softening. |

| Hardness (Shore A) | 20 to 80 | Shore A | Measures resistance to indentation. Softer silicone (lower Shore A) offers better sealing conformability and low closure force, ideal for irregular surfaces. Harder silicone (higher Shore A) provides better abrasion resistance and structural support, suited for higher pressure or dynamic applications. |

| Tensile Strength | 5 to 12 | MPa (Megapascals) | Indicates the maximum stress a material can withstand while being stretched or pulled before breaking. Important for seals subjected to tension or stretching during installation or operation. |

| Elongation at Break | 200% to 700% | % | The percentage increase in length a material can undergo before it fractures. Higher elongation signifies greater flexibility and ability to accommodate movement or vibration without tearing. |

| Compression Set (e.g., 22h @ 175°C) | 10% to 35% | % | The permanent deformation remaining after a compressive force is released. Lower values are critical for long-term sealing performance, indicating the material's ability to recover its original shape and maintain consistent sealing pressure, even after prolonged compression. |

| Specific Gravity | 1.1 to 1.3 | g/cm³ | The ratio of the density of the silicone to the density of water. Used for weight calculation and material identification. |

| Dielectric Strength | 18 to 25 | kV/mm | The maximum electric field strength that a silicone material can withstand without electrical breakdown. Essential for electrical insulation applications and seals in electrical enclosures. |

| UV/Ozone Resistance | Excellent | N/A | Superior resistance to degradation from ultraviolet radiation and ozone, which are common in outdoor environments. This prevents cracking, hardening, and discoloration, significantly extending the lifespan of outdoor seals like silicone weather stripping. |

| Chemical Resistance | Good for many acids, bases, alcohols, some oils (specific grades for enhanced resistance like Fluorosilicone) | N/A | Ability to withstand degradation from various chemicals. While standard silicone is inert, specialized formulations (e.g., Gap Solid Silicone Rubber Strip Anti Oil High Temp) are developed to combat specific aggressive media like oils, fuels, and solvents, preventing swelling or material breakdown. |

| Flame Retardancy | Self-extinguishing (certain grades, typically UL94 V-0 or HB) | N/A | Enhances safety in fire-prone environments, crucial for seals in public transport, electronics, and industrial settings. |

The Gap Solid Silicone Rubber Strip Anti Oil High Temp product from QZSEALS is specifically engineered to excel in these parameters, particularly its resistance to high temperatures and a broad range of oils. Its solid composition ensures high mechanical strength and excellent sealing performance even under significant pressure and continuous exposure to harsh media, making it a robust solution for the most demanding environments where standard materials would fail prematurely.

Manufacturing Process of Silicone Strip Seal

The production of a high-quality silicone strip seal is a complex process that demands precision engineering and stringent quality control. The most common and effective method for manufacturing continuous silicone strips is extrusion. This process ensures consistent cross-sectional profiles, uniform material properties throughout the length, and high production efficiency crucial for meeting industrial demands. QZSEALS employs state-of-the-art extrusion technology to produce its range of silicone seals, including the Gap Solid Silicone Rubber Strip Anti Oil High Temp.

Precision extrusion machinery ensures consistent quality in silicone strip seal production.

Detailed Manufacturing Steps for Silicone Extrusions:

-

Material Preparation & Compounding:

The foundation of a superior silicone strip lies in the quality of its raw materials and precise compounding. The process begins with high-purity polydimethylsiloxane (PDMS) polymers, which form the base silicone rubber. These polymers are then meticulously blended with various essential additives in a high-shear mixer to achieve the desired physical and chemical properties. Key additives include:

- Curing Agents (Vulcanizing Agents): Typically organic peroxides (e.g., dicumyl peroxide), these chemicals initiate the cross-linking process during heating, transforming the malleable compound into a resilient rubber.

- Reinforcing Fillers: Such as fumed silica or precipitated silica. These finely divided particles significantly enhance mechanical properties like tensile strength, tear strength, and abrasion resistance, giving the silicone strip its durability.

- Process Aids: To improve flow characteristics during extrusion.

- Pigments: If the final product requires specific coloring.

- Specialty Additives: For properties like enhanced oil resistance (critical for products like the Gap Solid Silicone Rubber Strip Anti Oil High Temp), flame retardancy, electrical conductivity, or anti-microbial properties.

The precision in weighing and mixing these components is paramount to ensuring the homogeneity and consistent performance of the final silicone product. Each formulation is developed to meet specific application requirements and industry standards.

-

Extrusion:

The thoroughly compounded silicone material, now resembling a thick dough or gum, is fed into an extruder machine. Inside the extruder, a rotating screw (or twin-screws in some advanced systems) pushes the silicone through a heated barrel. The heat reduces the viscosity of the compound, making it easier to flow. At the end of the barrel, the material is forced through a precisely shaped die. The internal geometry of this die defines the exact cross-sectional profile of the silicone strip seal (e.g., solid rectangular, square, D-profile, P-profile, U-channel, or complex custom shapes). The consistency of pressure, temperature, and screw speed throughout this stage is crucial to prevent profile distortion and ensure dimensional accuracy.

(Visual Representation: A schematic showing raw silicone compound feeding into an extruder, where a screw pushes it through a heated barrel and then through a die, forming a continuous profile.)

-

Curing (Vulcanization):

Immediately after exiting the extruder die, the uncured silicone strip, still soft and pliable, enters a continuous curing system. This is often a hot air oven, a salt bath, or an infrared/microwave vulcanization line. The elevated temperatures in the curing chamber activate the curing agents, initiating a chemical reaction that causes the silicone polymer chains to form robust cross-links. This irreversible process transforms the soft, plastic-like silicone into a strong, elastic, and thermoset rubber with stable physical properties. The duration and temperature of curing are critically controlled to ensure complete vulcanization, which directly impacts the seal's final hardness, tensile strength, elongation, and crucially, its compression set performance for long-term sealing integrity.

(Visual Representation: A flow diagram indicating the extruded silicone profile passing through a heated tunnel or chamber for vulcanization, emerging as a cured rubber strip.)

-

Cooling & Sizing:

Following the curing process, the now-cured silicone strip needs to be cooled down to stabilize its dimensions and facilitate subsequent handling. This typically involves passing through an air-cooling section or a water bath. Precise laser or optical measurement systems are often employed in-line during this stage to continuously monitor the dimensions of the strip, ensuring it meets the tight tolerance specifications outlined in standards like ISO 3302 or customer-specific drawings.

-

Cutting & Finishing:

Once cooled and dimensionally stable, the continuous silicone strip is cut to the desired lengths. This can be done automatically in-line by precision cutting machines or as a batch process for very long rolls. Depending on the end application, further finishing processes may include:

- Applying pressure-sensitive adhesive (PSA) backing for easy installation.

- Punching or drilling holes for specific mounting.

- Surface treatments for improved friction, aesthetic, or cleanability.

- Custom packaging for shipment.

-

Quality Control & Inspection:

Throughout the entire manufacturing journey, from raw material receipt to finished product packaging, rigorous quality control checks are paramount. This involves:

- Incoming Material Inspection: Verifying raw material purity and conformity.

- In-process Checks: Monitoring extruder temperatures, pressures, and dimensional consistency.

- Post-Cure Testing: Conducting comprehensive mechanical property tests on samples from each batch. This includes hardness (ASTM D2240), tensile strength, elongation at break (ASTM D412), and compression set (ASTM D395). Specific electrical, thermal, or chemical resistance tests may also be performed.

- Visual Inspection: For surface defects, inconsistencies, or foreign inclusions.

- Dimensional Verification: Ensuring compliance with specified tolerances (e.g., ISO 3302 for rubber extrusions).

Adherence to certified quality management systems like ISO 9001:2015 ensures consistent product excellence, traceability, and reliability, forming the bedrock of a reputable manufacturer's operations like QZSEALS.

Application Scenarios and Technical Advantages

The inherent versatility and superior properties of the silicone strip seal make it an indispensable component across an astonishingly broad array of industries. Its unique combination of extreme temperature resistance, chemical inertness, UV and ozone stability, and excellent flexibility translates into significant technical and operational advantages in critical sealing applications.

Key Applicable Industries:

- Automotive Industry: Used extensively for engine compartment gaskets (withstanding high temperatures and oils), window and door seals, vibration dampeners, and seals for electronic control units (ECUs). Silicone's ability to resist extreme temperatures, engine fluids, and environmental exposure is crucial for vehicle longevity and safety.

- Aerospace & Aviation: Employed in cabin seals, ducting seals, and sealing for sensitive electronic enclosures due to its performance stability across wide temperature and pressure differentials, as well as its flame retardancy in critical aircraft systems.

- Electronics & Electrical Engineering: Ideal for creating weatherproof seals for outdoor LED lighting fixtures, waterproof enclosures for telecommunication equipment, cable insulation, and sealing components in consumer electronics, benefiting from its excellent dielectric properties and environmental resistance.

- Medical & Pharmaceutical: Specified for tubing, peristaltic pump seals, seals in sterilization equipment (autoclaves), and diagnostic instruments. Medical-grade silicone (often USP Class VI certified) is biocompatible, non-leaching, and withstands repeated harsh sterilization cycles without degradation, ensuring patient safety and product purity.

- Food & Beverage Processing: Used for gaskets and seals in processing machinery, oven door seals, refrigerator gaskets, and dispensing equipment. FDA-compliant silicone grades ensure compliance with food safety regulations, preventing contamination and withstanding repeated cleaning cycles.

- HVAC & Construction: Widely used as silicone weather stripping, window seals, and door bottom seal rubber strip to improve thermal insulation, reduce air infiltration, and enhance soundproofing in residential, commercial, and industrial buildings, leading to significant energy savings and improved indoor comfort.

- Industrial Equipment & Heavy Machinery: Crucial for gaskets and seals in pumps, valves, heat exchangers, and processing tanks across sectors like petrochemical, metallurgy, chemical processing, water treatment (including give/drainage systems), and mining. Its resistance to corrosive chemicals, abrasives, and wide temperature swings ensures operational integrity and extends equipment lifespan.

- Home Appliances: Found in oven door seals, refrigerator and freezer door gaskets, dishwasher seals, and washing machine seals, where thermal insulation, water resistance, and durability under repeated use are essential.

Enhanced insulation and energy efficiency are key benefits of a high-quality silicone door seal strip.

Technical Advantages in Typical Application Scenarios:

- Exceptional Energy Efficiency (HVAC & Construction): As a silicone weather stripping or door bottom seal rubber strip, silicone forms a highly effective barrier against air drafts, dust, moisture, and sound infiltration. This capability dramatically reduces heat loss in winter and heat gain in summer, leading to substantial reductions in heating and cooling costs. For instance, well-sealed commercial buildings can see HVAC energy consumption drop by 15-25%, contributing directly to operational savings and a reduced carbon footprint.

- Superior Corrosion and Chemical Resistance (Petrochemical & Chemical): In aggressive chemical environments, many conventional rubbers rapidly swell, degrade, or lose their elasticity. Silicone's inherent chemical inertness allows it to resist a broad spectrum of acids, bases, solvents, and industrial fluids. This ensures long-term sealing integrity in pipes, tanks, and pumps, preventing costly and dangerous leaks, minimizing equipment damage, and extending the service life of critical infrastructure. The Gap Solid Silicone Rubber Strip Anti Oil High Temp is particularly effective in environments where both high temperatures and specific oil exposure are present, offering a reliable barrier where other materials fail.

- Reliable High-Temperature Stability (Ovens & Industrial Furnaces): Unlike EPDM or Neoprene, which can stiffen at low temperatures or degrade rapidly at high temperatures, silicone maintains its elasticity and sealing properties across an extreme range from -60°C to over +230°C. This ensures reliable performance in continuous high-heat applications like industrial ovens, autoclaves, vulcanizers, and heat exchangers. It prevents heat escape, maintains thermal process efficiency, and significantly reduces downtime associated with seal replacement.

- Extended Durability & Longevity: Silicone exhibits outstanding resistance to environmental aging factors such as UV radiation, ozone, and weathering. This means silicone seals do not crack, harden, or become brittle when exposed to outdoor elements or harsh industrial atmospheres. This superior resilience contributes to a significantly longer service life compared to organic rubbers, drastically reducing maintenance frequency and replacement costs over the operational life of the equipment.

- Effective Vibration Dampening and Acoustic Insulation: The intrinsic flexibility, elasticity, and excellent compression set properties of silicone make it an ideal material for absorbing mechanical shocks and vibrations. This protects sensitive electronic components, reduces mechanical stress on equipment, and significantly lowers operational noise levels in machinery, contributing to a safer and more comfortable working environment.

Choosing Your Provider: Manufacturer Comparison & Custom Solutions

Selecting the right manufacturer for your silicone strip seal needs is a critical decision that directly impacts product performance, project timelines, and overall cost-efficiency. While the market offers numerous suppliers, prioritizing those with demonstrated expertise, robust quality control, advanced manufacturing capabilities, and a commitment to customer-centric solutions is paramount to ensuring optimal outcomes and a reliable supply chain. QZSEALS, with years of experience, exemplifies these qualities.

Key Factors for Manufacturer Comparison:

| Feature | Standard Supplier / Commodity Provider | Premier Supplier (e.g., QZSEALS) | Direct Impact on Customer/Project |

|---|---|---|---|

| Material Quality & Sourcing | May use generic or inconsistent raw materials; less transparency on origin. | Utilizes certified, traceable, high-grade silicone polymers (e.g., from top-tier global suppliers like Wacker, Momentive, Dow Corning). | Ensures consistent product performance, predictable lifespan, and compliance with specific industry standards (e.g., FDA, RoHS), reducing risk of failures. |

| Manufacturing Process & Technology | Basic extrusion equipment; less stringent process controls. | Employs advanced precision extrusion machinery, continuous in-line vulcanization, and often operates under ISO 9001:2015 certified systems. | Guarantees highly uniform dimensions, consistent physical properties (hardness, tensile strength), higher reliability, and significantly fewer manufacturing defects, leading to easier installation and superior sealing. |

| Customization Capabilities & Engineering Support | Limited range of standard profiles; high Minimum Order Quantity (MOQ) for custom designs; minimal engineering assistance. | Extensive custom tooling capability; in-house engineering team provides expert design consultation for complex profiles and specialized material formulations. | Allows for truly tailored sealing solutions optimized for unique application needs, often leading to better performance and long-term cost-effectiveness compared to off-the-shelf compromises. |

| Certifications & Industry Standards Adherence | May lack specific product certifications or adherence to strict industry standards. | Demonstrates adherence to international standards like ISO, FDA (21 CFR 177.2600), RoHS, REACH; possesses capabilities for producing materials meeting USP Class VI, UL listings, and specific automotive or aerospace specs. | Provides verifiable proof of product safety, quality, and compliance for highly regulated industries, building immense trust and simplifying qualification processes for clients. |

| Technical Support & Research & Development (R&D) | Minimal or reactive technical support; limited R&D investment. | Dedicated team of material scientists and application engineers; proactive problem-solving; continuous investment in R&D for new formulations and process improvements. | Offers invaluable assistance with material selection, design optimization, troubleshooting, and staying ahead of evolving industry demands through innovation. |

| Lead Time & Delivery Reliability | Variable lead times; potential for delays and inconsistent delivery. | Optimized production schedules, efficient supply chain management, reliable delivery forecasts, and established logistics partnerships. | Minimizes project delays, allows for accurate inventory planning, and ensures consistent supply, crucial for continuous operations. |

| After-Sales Support & Warranty | Limited or no clear warranty; difficult to get post-purchase assistance. | Comprehensive product warranty (e.g., 1-year against manufacturing defects), responsive customer service, and ongoing technical assistance post-purchase. | Provides peace of mind, ensures prompt resolution of any issues, and fosters a long-term, trustworthy partnership. |

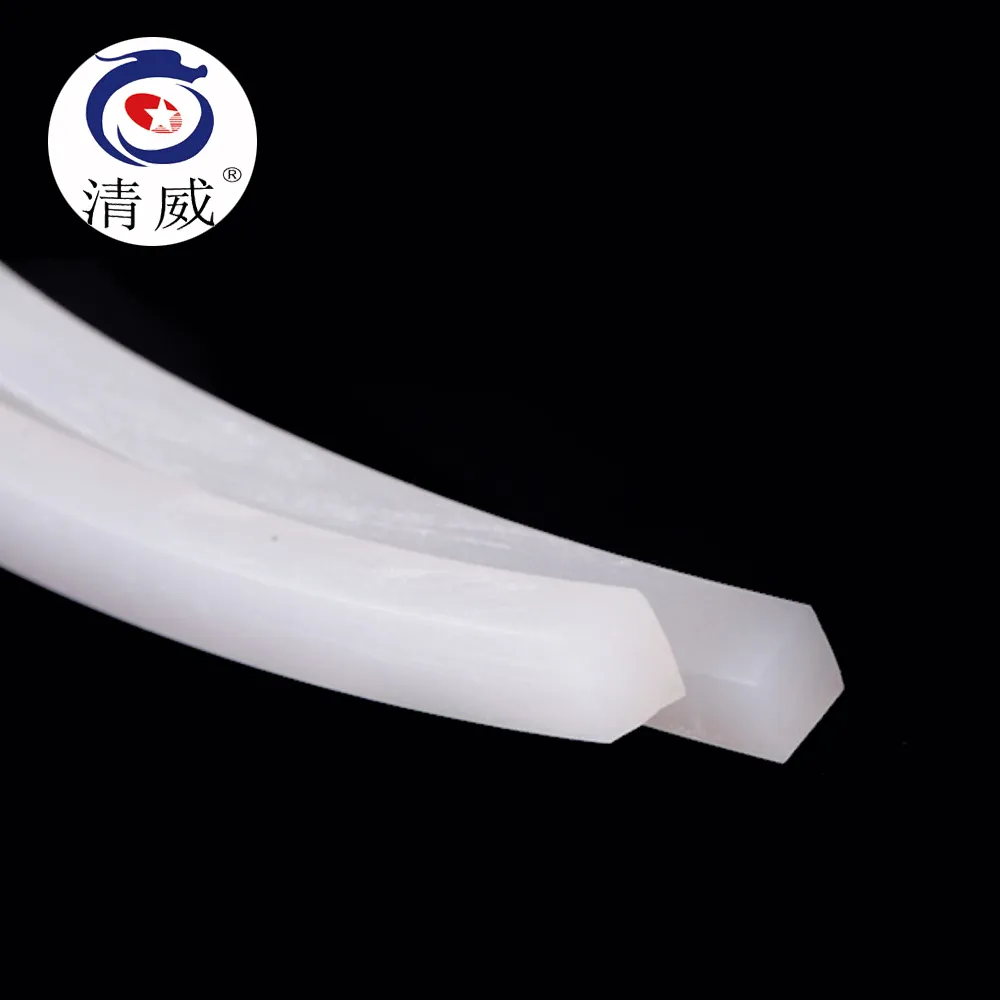

Custom-engineered silicone strip seal profiles designed for unique application requirements.

Tailored Customization Solutions:

For applications where off-the-shelf solutions cannot meet the precise demands, leading manufacturers like QZSEALS excel in providing comprehensive custom solutions. This collaborative process ensures that the final silicone strip seal is perfectly optimized for its intended environment:

- Detailed Design Consultation: Our engineers work closely with clients to thoroughly understand their specific application requirements, including operational temperatures, chemical exposures, mechanical stresses, dimensional constraints, and expected service life.

- Advanced Material Formulation: Leveraging deep material science expertise, we develop bespoke silicone compounds. This can involve adjusting hardness, enhancing resistance to specific oils, fuels, or chemicals, optimizing high or low-temperature performance, incorporating flame retardancy, or achieving specific color matching and aesthetic properties.

- Precision Tooling Design & Prototyping: For unique profiles, custom extrusion dies are meticulously designed using CAD/CAM software. Rapid prototyping services allow for quick production of samples for client testing and validation, enabling iterative refinement before full-scale production.

- Customized Production & Stringent Quality Assurance: Once the design and material are approved, the custom seals are manufactured with the same rigorous quality controls as our standard products. Each batch undergoes comprehensive testing to ensure it meets all defined performance parameters and dimensional tolerances, guaranteeing consistency and reliability.

This bespoke approach ensures that clients receive a silicone strip seal that is not just a fit, but a perfect solution, maximizing performance, extending lifespan, and ultimately providing significant long-term cost-efficiency.

Real-World Application Cases & Client Feedback

The true measure of a product's efficacy and a manufacturer's reliability lies in its performance in challenging, real-world scenarios and the tangible feedback from satisfied clients. The Gap Solid Silicone Rubber Strip Anti Oil High Temp and other high-performance silicone strip seal products from QZSEALS have consistently demonstrated exceptional reliability and superior performance across diverse and demanding applications, validating our commitment to quality and engineering excellence.

A custom silicone strip seal integrating seamlessly into complex industrial machinery for enhanced sealing and operational integrity.

Case Study 1: High-Temperature Oven Seal for Commercial Bakeries and Industrial Curing

A prominent manufacturer of commercial baking ovens and industrial curing chambers faced persistent issues with their existing door seals. The seals, made from conventional elastomers, were degrading rapidly due to continuous exposure to temperatures ranging from 180°C to 250°C. This led to significant heat loss, increased energy consumption (with reported 15% higher energy bills), inconsistent product quality due to uneven heating, and frequent seal replacements every 6-9 months, resulting in considerable maintenance costs and production downtime. By collaborating with QZSEALS, the client transitioned to a custom-formulated, high-temperature-resistant silicone strip seal. The new seals were engineered with a specialized silicone compound capable of withstanding continuous temperatures up to 280°C with extremely low compression set. The result was a dramatic improvement: the silicone seals maintained their elasticity and sealing integrity for over five years, reducing maintenance costs by over 70% and improving oven thermal efficiency by an estimated 12%, directly impacting their bottom line.

Case Study 2: Oil-Resistant Gasket for Heavy-Duty Hydraulic Systems in Construction Equipment

An Original Equipment Manufacturer (OEM) specializing in heavy-duty construction equipment, particularly hydraulic excavators and loaders, encountered critical seal failures within their hydraulic power units. Standard nitrile rubber gaskets, while generally oil-resistant, were swelling and deteriorating rapidly when exposed to aggressive synthetic hydraulic fluids and operating temperatures often exceeding 100°C under high pressure. This led to frequent fluid leaks, environmental contamination risks, and costly unscheduled downtime for equipment repair. QZSEALS recommended and supplied the Gap Solid Silicone Rubber Strip Anti Oil High Temp. This specific product, engineered with an advanced silicone formulation, offered superior chemical compatibility with a wide range of hydraulic oils and maintained its physical integrity and low compression set even at elevated temperatures. The implementation resulted in a remarkable extension of the Mean Time Between Failures (MTBF) by over 400%, drastically reducing leak-related maintenance by 85% and improving overall equipment reliability in harsh field conditions. The client reported significant savings from reduced fluid loss and increased equipment availability.

Case Study 3: Advanced Weather Sealing for Smart City Infrastructure and Public Displays

A large-scale smart city development project required extremely durable and reliable weather stripping for its network of outdoor electronic enclosures, intelligent traffic light housings, digital public information kiosks, and security camera units. These components are continuously exposed to a wide range of environmental stressors, including heavy rain, dust storms, intense UV radiation, and extreme temperature swings (from -25°C in winter to +55°C in summer). The project's stringent specifications demanded an IP67 environmental protection rating to safeguard sensitive electronics. Utilizing a specially designed silicone weather stripping and silicone door seal strip from QZSEALS, the project successfully achieved and maintained the required ingress protection ratings. The silicone's excellent UV, ozone, and weathering resistance ensured no signs of degradation, cracking, or hardening even after 10 years of continuous outdoor exposure. This vastly reduced the need for costly field repairs and component replacements, contributing to the long-term sustainability and operational efficiency of the smart city infrastructure. The long lifespan of the seals minimized the total cost of ownership for the city planners.

Seamless installation of silicone weather stripping for improved building performance and longevity.

Ensuring Trust and Reliability: Guarantees and Support

At QZSEALS, we understand that exceptional product quality is only one part of the equation for long-term customer satisfaction. Our commitment to excellence extends to every facet of our operations, encompassing robust support, transparent policies, and an unwavering dedication to building trustworthy partnerships. Our silicone strip seal products, including the advanced Gap Solid Silicone Rubber Strip Anti Oil High Temp, are meticulously manufactured and backed by comprehensive guarantees, ensuring peace of mind for our clients.

Our Commitment to Trustworthiness and Customer Assurance:

- Rigorous Quality Assurance & International Certifications: All our products are manufactured under the stringent guidelines of an ISO 9001:2015 certified quality management system. This ensures consistent quality from raw material sourcing to final product inspection. Our silicone materials adhere to global regulatory standards such as FDA 21 CFR 177.2600 (for food contact applications), RoHS (Restriction of Hazardous Substances), and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) compliance, where applicable. We regularly engage accredited third-party laboratories to conduct independent testing, validating material properties and performance against industry benchmarks, thereby reinforcing our product integrity.

- Transparent Delivery & Predictable Lead Times: We provide clear, realistic, and accurate lead time estimates at the point of order confirmation, avoiding unpleasant surprises. For our standard silicone strip seal products, typical delivery ranges from 5-10 business days. For highly customized solutions involving new tooling or complex formulations, initial production runs may require 2-4 weeks. We leverage a robust and efficient global logistics network to ensure timely, secure, and cost-effective delivery to our clients worldwide, minimizing project delays and supporting efficient inventory management.

- Comprehensive Product Warranty: We stand firmly behind the quality and durability of our products. All our silicone strip seals are supplied with a standard 1-year warranty against manufacturing defects and material failures under normal operating conditions. This commitment underscores our confidence in the superior quality and robust performance of our silicone solutions. For specific high-value or long-term projects, extended warranty options can be discussed to provide an even greater level of assurance.

- Dedicated & Knowledgeable Customer Support: Our team comprises highly experienced technical sales representatives and skilled application engineers who are readily available to assist clients at every stage. This includes expert pre-sales consultation to help select the optimal silicone formulation and profile, guidance on installation best practices, and responsive after-sales support for any technical queries or troubleshooting requirements. We prioritize building lasting client relationships through proactive communication and unparalleled service.

- Full Batch Traceability: Every batch of our silicone products is fully traceable from the initial raw material acquisition (including specific lot numbers from our certified suppliers) through each stage of the manufacturing process to the final finished good. This comprehensive traceability ensures full accountability and allows for rapid identification and resolution of any potential quality anomalies, providing an additional layer of trust and reliability.

Frequently Asked Questions (FAQ) about Silicone Strip Seals

Q1: What makes silicone a superior material for strip seals compared to other common rubbers like EPDM or Neoprene?

A1: Silicone rubber offers several distinct advantages. It exhibits superior performance across an exceptionally wide temperature range (typically -60°C to +230°C, with special grades up to +300°C), whereas EPDM and Neoprene have more limited thermal capabilities. Silicone also boasts excellent UV and ozone resistance, meaning it will not crack or degrade when exposed to sunlight or outdoor atmospheric conditions, unlike many organic rubbers. Furthermore, silicone maintains an exceptionally low compression set, ensuring it retains its sealing force over time. While EPDM is good for outdoor weathering and Neoprene for oil resistance, silicone often combines many of these benefits, making it ideal for demanding environments where longevity, high temperature, and environmental resistance are critical. Our Gap Solid Silicone Rubber Strip Anti Oil High Temp, for example, specifically addresses the need for both high temperature and enhanced oil resistance, an area where many conventional rubbers fall short.

Q2: Can silicone strip seals be used in food-grade or medical applications, and what certifications are required?

A2: Yes, absolutely. Many silicone formulations are specifically engineered and manufactured to meet stringent requirements for food contact and medical applications. For food-grade use, compliance with FDA 21 CFR 177.2600 is essential, ensuring the material is non-toxic and suitable for repeated contact with food. For medical and pharmaceutical applications, certifications such as USP Class VI are critical, guaranteeing biocompatibility, non-reactivity, and the ability to withstand repeated sterilization cycles (e.g., autoclaving, ETO gas). These grades are also typically odorless, tasteless, and non-leaching, making them safe and reliable for sensitive environments where purity is paramount.

Q3: How do I determine the correct hardness (Shore A) for my specific silicone strip seal application?

A3: The optimal hardness, measured in Shore A, is crucial and depends heavily on your application's specific requirements. Softer silicones (typically 20-40 Shore A) offer superior conformability to irregular surfaces, excellent sealing with minimal closure force, and good vibration dampening. They are often used for general sealing or when the mating surfaces are not perfectly flat. Harder silicones (ranging from 60-80 Shore A) provide greater abrasion resistance, higher tensile strength, and better structural support. These are typically chosen for applications requiring higher pressure sealing, where the seal acts as a gasket under significant compression, or where the seal may experience wear. It's best to consult with our technical team to discuss your specific operating pressures, gap sizes, and surface finishes for a precise recommendation.

Q4: What is compression set, and why is it so critically important for the long-term performance of a silicone strip seal?

A4: Compression set refers to the permanent deformation (or inability to fully rebound to its original thickness) that occurs when an elastomeric material is subjected to a constant compressive force over a period, especially at elevated temperatures. A low compression set is vital because it indicates the silicone seal will effectively rebound and maintain its sealing force and integrity over its operational lifespan, preventing leaks and ensuring consistent performance. If a seal has a high compression set, it will gradually lose its ability to exert pressure on the mating surfaces, leading to seal failure. High-quality silicone, like that used in our Gap Solid Silicone Rubber Strip Anti Oil High Temp, is engineered for exceptionally low compression set to guarantee long-term sealing reliability even in demanding thermal cycling conditions.

Q5: Can silicone strip seals be supplied with adhesive backing for easier installation?

A5: Yes, absolutely. Many of our silicone strip seals, particularly those used as silicone weather stripping or a door bottom seal rubber strip, can be supplied with high-performance pressure-sensitive adhesive (PSA) backing. This self-adhesive feature significantly simplifies and accelerates installation, reduces labor costs, and provides a secure, immediate bond to various clean, dry surfaces such as metal, plastic, or wood. It is crucial to specify the application environment (e.g., high temperature, outdoor exposure) so we can recommend the appropriate type of adhesive for optimal adhesion and longevity.

Q6: What is the typical lifespan of a silicone strip seal, and how is it affected by operating conditions?

A6: The lifespan of a silicone strip seal is highly dependent on the specific application conditions, including continuous operating temperatures, exposure to chemicals or harsh fluids, mechanical stress (e.g., compression, abrasion), and environmental factors like UV radiation and ozone. However, due to its exceptional inherent resistance to aging, UV, ozone, and extreme temperatures, high-quality silicone generally significantly outperforms organic rubbers. In many static applications under moderate conditions, a premium silicone seal can effectively last for 10-20 years or even longer. For dynamic or highly extreme conditions, accelerated aging tests and real-world application data provide reliable lifespan predictions, often showing superior performance compared to alternatives.

Q7: How do I ensure compatibility of a silicone strip seal with specific oils or aggressive chemicals?

A7: While general-purpose silicone has good overall chemical inertness, its resistance to specific oils, fuels, or aggressive chemicals can vary. For applications involving direct contact with such media, it's crucial to select a specially formulated silicone compound. For instance, our Gap Solid Silicone Rubber Strip Anti Oil High Temp is engineered to offer enhanced resistance to oil degradation. For other highly aggressive chemicals, such as concentrated acids, strong bases, or certain solvents, specialized variants like Fluorosilicone (FVMQ) may be recommended, as they offer superior resistance to a broader range of chemicals and fuels compared to standard silicone. It is always recommended to consult our technical team and review detailed chemical compatibility charts for your specific environment, and ideally, perform in-situ compatibility testing to ensure optimal performance and safety.

Conclusion: The Enduring Value of Silicone Strip Seal

The ubiquity and enduring performance of the silicone strip seal underscore its critical and growing role in modern industrial and consumer applications. From providing essential thermal barriers in high-temperature industrial ovens and safeguarding delicate electronics in outdoor environments to ensuring airtight and watertight integrity in residential and commercial buildings, its unique blend of properties offers unparalleled reliability and longevity. As global industries continue to evolve towards more demanding operational parameters, stricter environmental regulations, and a greater emphasis on energy efficiency and sustainability, the demand for advanced sealing solutions like the Gap Solid Silicone Rubber Strip Anti Oil High Temp will only continue to grow. By prioritizing expert manufacturers who not only adhere to rigorous quality standards but also offer comprehensive customization capabilities and provide unwavering technical and customer support, businesses can fully unlock the immense potential of silicone sealing technology. This strategic approach ensures optimal performance, drastically reduces maintenance requirements, and delivers significant cost savings over the entire product lifecycle, proving that a high-quality silicone strip seal is an investment in long-term operational excellence and reliability.

References and Further Reading:

- Grand View Research. (2023). Industrial Seals Market Size, Share & Trends Analysis Report By Material (Metal, Elastomer, Thermoplastic), By Product, By End-use (Oil & Gas, Chemical, Power), By Region, And Segment Forecasts, 2023 - 2030. Retrieved from https://www.grandviewresearch.com/industry-analysis/industrial-seals-market

- Elastomer, Rubber and Polymer Technology Research Group (ERPT). (Various publications). Articles from leading academic journals such as *Polymer Engineering & Science* and *Rubber Chemistry and Technology*. Accessible via major academic databases or institutional libraries.

- ASTM International. (Ongoing). Standards for Rubber and Rubber-like Materials. Key standards include ASTM D2000 (Standard Classification System for Rubber Products in Automotive Applications), ASTM D412 (Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension), and ASTM D2240 (Standard Test Method for Rubber Property—Durometer Hardness). Available via the ASTM website.

- Silicone Industry Association of Japan (SIAJ). (Various reports). Technical overviews and market trends for silicone products.

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025