Durable Silicone Strip Seal for Effective Door Weather Stripping

In the vast landscape of modern industrial and domestic applications, effective sealing solutions are paramount for performance, safety, and energy efficiency. Among the myriad of available options, the silicone strip seal stands out as a superior choice, renowned for its unparalleled durability, extreme temperature resistance, and chemical inertness. This comprehensive guide delves into the world of silicone sealing, exploring its industry trends, technical specifications, diverse applications, and the sophisticated manufacturing processes that bring these critical components to life.

The Evolving Landscape of Sealing Technology: Industry Trends for Silicone Strip Seal

The global market for sealing solutions is experiencing robust growth, driven by increasing demands in construction, automotive, electronics, and renewable energy sectors. Within this dynamic environment, silicone strip seal products are seeing significant adoption due to their inherent advantages over traditional rubber or plastic alternatives. Key trends indicate a strong shift towards high-performance materials capable of withstanding harsh environments, reducing energy consumption, and providing extended service life.

- Sustainability Focus: Manufacturers and end-users are increasingly prioritizing eco-friendly and long-lasting materials. Silicone, with its exceptional durability, reduces the frequency of replacements, thus minimizing waste. Its inert nature also makes it a safer choice for sensitive applications.

- Rise of Smart Buildings: The integration of smart technologies in buildings necessitates highly efficient sealing for improved insulation, soundproofing, and air quality. Products like silicone weather stripping and silicone door seal strip are crucial for achieving stringent energy efficiency standards.

- Electrification of Vehicles: The automotive industry's pivot towards electric vehicles (EVs) creates new demands for lightweight, high-temperature resistant, and electrically insulating seals for battery packs and electronic components.

- Precision Engineering: As industries require tighter tolerances and more reliable performance, the demand for precision-engineered silicone strip seal products manufactured to exacting standards (e.g., ASTM D2000) is accelerating.

- Customization and Specialization: The "one-size-fits-all" approach is diminishing. There's a growing need for customized sealing solutions tailored to specific application requirements, material grades, and profiles.

Unpacking the Performance: Technical Parameters of Silicone Strip Seal

The superior performance of a silicone strip seal is attributed to its unique molecular structure. Polysiloxanes, the backbone of silicone, provide exceptional thermal stability and flexibility. Understanding the key technical parameters is crucial for selecting the right seal for any application.

Common Technical Specifications for Silicone Strip Seals

| Parameter | Unit | Typical Range for Standard Silicone | Relevance / Explanation |

|---|---|---|---|

| Hardness (Durometer) | Shore A | 20 - 80 | Measures resistance to indentation. Softer silicone (lower Shore A) offers better sealing conformability, while harder silicone resists compression and abrasion better. |

| Tensile Strength | MPa (psi) | 5 - 12 (725 - 1740) | The maximum stress a material can withstand before breaking when stretched. Indicates material strength and durability. |

| Elongation at Break | % | 200 - 700 | The percentage increase in length a material can undergo before breaking. Signifies flexibility and elasticity. |

| Tear Strength | kN/m (ppi) | 15 - 35 (85 - 200) | Resistance to the propagation of a tear. Crucial for dynamic applications or seals exposed to potential damage. |

| Temperature Range | °C (°F) | -50 to +230 (-58 to +446) | The range of temperatures over which the material maintains its optimal properties. Special grades can extend this range. |

| Compression Set | % | 5 - 20 (at 22h @ 175°C) | The permanent deformation of a material after being subjected to a constant compressive force for a period. Lower values indicate better sealing capability over time. |

| Specific Gravity | g/cm³ | 1.1 - 1.25 | Ratio of the material's density to the density of water. Affects weight and material consumption. |

| Flame Retardancy | UL94 V-0, HB | Varies by grade | Ability to resist combustion. Essential for applications requiring fire safety. |

| Chemical Resistance | Excellent | Acids, Bases, Oils (Specific Grades) | Resistance to degradation when exposed to various chemicals. Specialized grades offer enhanced resistance to oils (like in our featured product) and specific solvents. |

| Dielectric Strength | kV/mm | >20 | The maximum electric field that the material can withstand intrinsically without breaking down. Important for electrical insulation applications. |

These parameters are often measured according to international standards such as ASTM D2000, ISO 34, ISO 37, and ISO 815, ensuring consistency and reliability across the industry.

Where Innovation Meets Application: Diverse Scenarios for Silicone Strip Seal

The versatility of silicone strip seal allows it to be utilized across an astonishing array of industries and applications, providing critical sealing, insulation, and protective functions.

- Construction & Architecture:

- Silicone weather stripping for windows and doors significantly improves thermal insulation, reduces energy costs, and prevents drafts and water ingress.

- Wood door weather stripping often uses silicone for its excellent long-term performance and aesthetic compatibility.

- Expansion joints, glazing seals, and facade sealing in modern buildings.

- Automotive Industry:

- Engine compartment seals due to high-temperature resistance.

- Door and window seals for superior acoustics and weatherproofing.

- Gasketing in lighting systems and electronic components.

- HVAC Systems: Sealing air ducts, plenums, and ventilation systems to prevent air leakage, ensuring system efficiency and indoor air quality.

- Appliance Manufacturing: Seals for ovens, refrigerators, washing machines, and dishwashers, where temperature extremes or moisture resistance are critical.

- Electronics: Protecting sensitive electronic components from dust, moisture, and temperature fluctuations in enclosures and housings.

- Medical & Pharmaceutical: Due to its biocompatibility and ability to withstand sterilization, silicone is ideal for medical devices, tubing, and cleanroom seals. FDA-compliant grades are essential here.

- Food Processing: Seals for ovens, freezers, and processing equipment, where non-toxic and high-temperature resistant materials are required (FDA grades).

- Industrial Machinery: Gasketing for control panels, pump housings, and equipment enclosures where resistance to oils, chemicals, and vibration is necessary.

- Marine Applications: Seals for hatches, portholes, and deck equipment, offering excellent resistance to saltwater, UV, and extreme weather.

The Unrivaled Edge: Technical Advantages of Silicone

Compared to other elastomer materials, silicone offers a distinct set of advantages that make the silicone strip seal a preferred choice for demanding applications.

- Extreme Temperature Resistance: Silicone maintains its flexibility and sealing properties across a vast temperature range, typically from -50°C to +230°C, with special grades extending even further. This makes it ideal for both cryogenic and high-heat environments.

- Excellent UV and Ozone Resistance: Unlike organic rubbers, silicone does not degrade or crack when exposed to prolonged sunlight (UV radiation) or ozone, ensuring long-term outdoor performance. This is crucial for applications like door bottom seal rubber strip exposed to elements.

- Chemical Inertness: Silicone is largely unaffected by water, steam, many chemicals, acids, and bases. While not universally chemical resistant, specific formulations offer enhanced resistance to oils and industrial fluids, as seen in our product: `Gap Solid Silicone Rubber Strip Anti Oil High Temp`.

- Electrical Insulation: Silicone possesses excellent dielectric properties, making it an effective electrical insulator, crucial for electronic and electrical enclosures.

- Biocompatibility & Food Grade Compliance: Certain silicone grades are inert and non-toxic, complying with FDA and USP Class VI standards, making them safe for medical and food contact applications.

- Flexibility & Compression Set Resistance: Silicone retains its elasticity and shape even after prolonged compression, ensuring a reliable, long-lasting seal. A low compression set means it won't permanently deform, maintaining its sealing integrity over time.

- Vibration Damping & Sound Insulation: The inherent flexibility and molecular structure of silicone allow it to absorb vibrations and provide superior sound dampening, enhancing comfort and reducing noise pollution.

From Raw Material to Finished Product: The Manufacturing Process of a Silicone Strip Seal

The production of a high-quality silicone strip seal involves a precise and controlled manufacturing process, ensuring consistency, dimensional accuracy, and optimal material properties. While specific techniques may vary, extrusion is the primary method for producing continuous strips.

Detailed Manufacturing Steps for Silicone Strip Seal:

-

①Material Preparation (Compounding): High-purity silicone polymers (polysiloxanes) are blended with various additives such as curing agents (peroxides or platinum catalysts), fillers (silica for strength), colorants, and specialized additives (e.g., oil-resistant agents for products like Gap Solid Silicone Rubber Strip Anti Oil High Temp). This compounding process determines the final properties of the silicone. This step is critical for achieving specific hardness, tensile strength, and chemical resistance.

-

②Extrusion: The compounded silicone material is fed into an extruder. Inside the extruder, a screw mechanism pushes the silicone through a heated barrel and then through a custom-designed die (tooling). The die shapes the silicone into the desired cross-sectional profile of the silicone strip seal. This method allows for continuous production of complex shapes and long lengths.

-

③Curing (Vulcanization): Immediately after extrusion, the still-soft silicone profile enters a continuous curing oven or vulcanization tunnel. Here, under controlled heat (and sometimes pressure), the curing agent initiates a cross-linking reaction within the silicone polymer. This process transforms the material from a soft, malleable state into a stable, elastic rubber, giving it its permanent physical properties and shape. Different curing methods, like hot air vulcanization (HAV) or salt bath curing, are used depending on the product and desired finish.

-

④Cooling & Sizing: After curing, the now solid silicone strip is carefully cooled to stabilize its dimensions. Precision rollers or pullers guide the strip, ensuring consistent sizing and preventing distortion before cutting.

-

⑤Cutting & Finishing: The continuous strip is then cut to precise lengths as per customer specifications. Further finishing operations may include punching holes, applying adhesive backing, or creating custom end-shapes.

-

⑥Quality Control & Inspection: Throughout the entire process, rigorous quality control checks are performed. This includes:

- Material Testing: Verifying raw material consistency and compound properties (e.g., hardness, tensile strength).

- Dimensional Inspection: Using optical sensors or calipers to ensure the extruded profile meets specified tolerances.

- Visual Inspection: Checking for surface defects, inconsistencies, or foreign particles.

- Performance Testing: Batch testing of finished products for properties like compression set, temperature resistance, and specific chemical resistance (e.g., oil resistance for the Gap Solid Silicone Rubber Strip Anti Oil High Temp). Compliance with standards like ISO and ASTM is confirmed here.

-

⑦Packaging & Shipping: Finally, the finished silicone strip seal products are carefully packaged to prevent damage during transit and prepared for delivery.

This meticulous process ensures that each silicone strip seal meets the highest standards of quality, performance, and durability, providing a reliable sealing solution for its intended application.

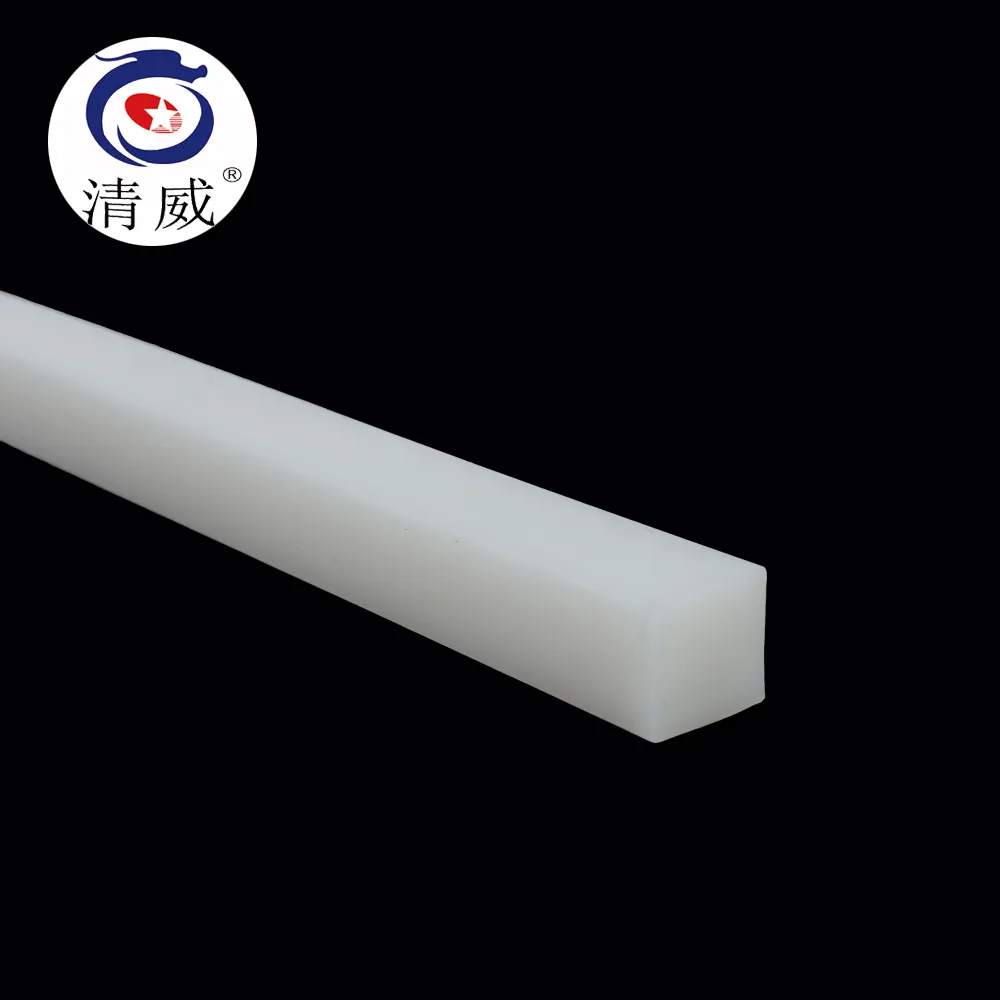

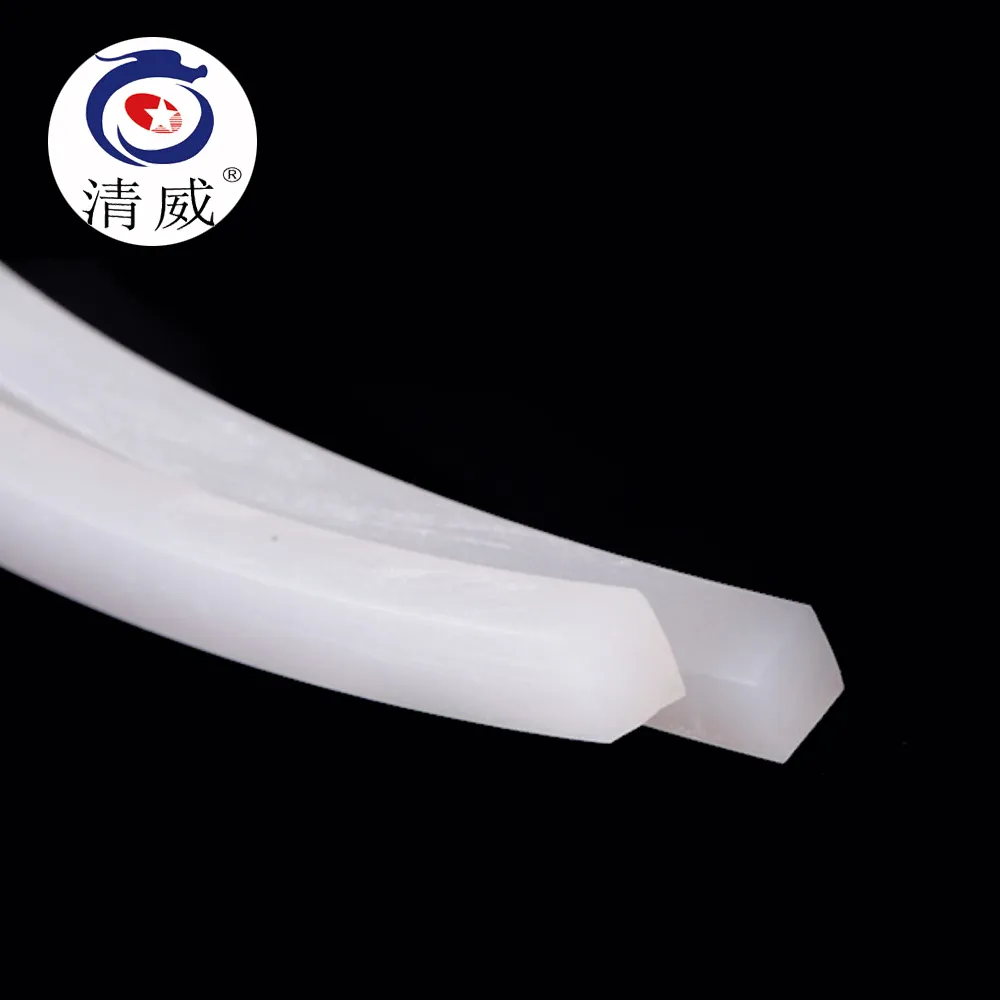

Featured Product: Gap Solid Silicone Rubber Strip Anti Oil High Temp

One excellent example of a highly specialized silicone strip seal is our Gap Solid Silicone Rubber Strip Anti Oil High Temp. This product is engineered to address the demanding requirements of environments where conventional silicone might fall short due to exposure to oils and high temperatures.

Key Features & Advantages:

- Enhanced Oil Resistance: Formulated with special additives, this strip offers superior resistance to various oils and greases, making it ideal for machinery, automotive, and industrial applications where lubricant exposure is common. This significantly extends its lifespan compared to standard silicone in such environments.

- High Temperature Stability: Capable of withstanding continuous temperatures up to 250°C (482°F) and intermittent peaks even higher, it ensures reliable sealing in extreme heat conditions.

- Solid Profile: The solid construction provides excellent mechanical strength and a robust seal, preventing compression set and maintaining integrity over time.

- Durability & Longevity: Designed for prolonged use, it resists aging, UV, and ozone, reducing maintenance and replacement costs.

- Versatile Applications: Perfect for sealing gaps in industrial ovens, processing equipment, engine compartments, hydraulic systems, and any application requiring a seal that stands up to both high heat and oil.

Learn more about this product: Gap Solid Silicone Rubber Strip Anti Oil High Temp

Choosing Your Partner: Manufacturer Comparison and Quality Assurance

Selecting the right manufacturer for your silicone strip seal needs is as crucial as selecting the right material. A reliable manufacturer offers not just a product, but a comprehensive solution backed by expertise, experience, and a commitment to quality.

- Expertise & Experience: Look for manufacturers with extensive experience in silicone extrusion, understanding the nuances of material compounding, die design, and curing processes. Years of service in the industry (e.g., "over 20 years in custom rubber extrusion") are strong indicators of deep knowledge.

- Quality Certifications: Adherence to international quality management standards like ISO 9001:2015 is paramount. This ensures consistent quality control throughout the manufacturing process, from raw material inspection to final product testing.

- Material Compliance: For specialized applications, verify that the manufacturer offers materials compliant with industry-specific standards such as FDA 21 CFR 177.2600 for food contact, USP Class VI for medical devices, or RoHS/REACH for environmental compliance.

- Customization Capabilities: A top-tier manufacturer should offer comprehensive customization services, including design assistance, custom tooling, and specific material formulations to meet unique application challenges.

- Testing & Validation: Reputable manufacturers perform rigorous in-house testing (e.g., hardness, tensile, compression set, specific gravity, chemical resistance tests) to validate product performance against specifications. Ask for test reports and certificates of conformity.

- Customer Support & Technical Assistance: A strong commitment to pre-sales consultation and post-sales support, including technical advice on material selection, installation, and troubleshooting.

- Supply Chain Reliability: Evaluate their ability to ensure consistent supply, on-time delivery, and responsiveness to demand fluctuations.

By focusing on these criteria, you can ensure a partnership that delivers not only high-quality silicone strip seal products but also reliability and value.

Tailored to Your Needs: Customization Solutions for Silicone Strip Seal

While standard profiles are available, many applications require a uniquely designed silicone strip seal to achieve optimal performance. Customization is a key strength of silicone extrusion, allowing for precise adaptation to specific operational demands.

- Profile Design: From simple rectangular strips to complex multi-lumen or bulb profiles (like P-strips, D-strips, U-channels), manufacturers can create custom dies to match exact geometric requirements. This is crucial for achieving a perfect fit and seal against irregular surfaces.

- Material Formulation: Tailoring the silicone compound is essential. This includes:

- Hardness (Durometer): Adjusting Shore A hardness from very soft (20 Shore A) for conformability to very hard (80 Shore A) for mechanical strength.

- Specialized Properties: Adding conductive fillers, flame retardants, anti-microbial agents, or enhancing resistance to specific chemicals or extreme temperatures (e.g., for products requiring extreme oil resistance like Gap Solid Silicone Rubber Strip Anti Oil High Temp).

- Color Matching: Producing seals in specific colors for aesthetic integration or functional coding.

- Adhesive Backing: Applying pressure-sensitive adhesive (PSA) backing for easier installation. This can be acrylic or silicone-based, depending on environmental exposure (temperature, moisture).

- Fabrication & Finishing: Secondary operations like cutting to exact lengths, splicing into O-rings or endless gaskets, punching holes, notching, or bonding different profiles.

- Prototyping & Tooling: For custom profiles, manufacturers typically offer rapid prototyping services and in-house tooling capabilities, allowing for quick iteration and precise die creation.

Partnering with a manufacturer offering robust customization ensures that your silicone strip seal solution is not just off-the-shelf, but perfectly engineered for your unique challenge.

Proven Performance: Real-World Application Cases

The efficacy of silicone strip seal solutions is best demonstrated through their successful deployment in diverse, challenging environments. These illustrative cases highlight the tangible benefits of choosing silicone.

- Case Study 1: Energy Efficiency in Commercial Buildings

A large commercial complex struggled with significant energy loss due to poor sealing around windows and doors, leading to high HVAC costs. By replacing old, degraded foam seals with custom-designed silicone weather stripping, the building achieved a 15% reduction in energy consumption. The silicone's superior longevity and resistance to UV and temperature fluctuations ensured long-term performance, unlike the previous material which degraded within a few years.

- Case Study 2: Noise Reduction in Residential Settings

Residents in urban apartments frequently complained about external noise intrusion. A solution involving specialized silicone door seal strip and sound-dampening window seals was implemented. The silicone's excellent compression set and flexibility provided an airtight seal, significantly reducing noise levels and enhancing resident comfort. The durability of the silicone also meant these seals would not stiffen or crack, maintaining acoustic integrity for years.

- Case Study 3: Sealing in High-Temperature Industrial Ovens

A food processing plant experienced frequent seal failures in its industrial baking ovens due to extreme temperatures (up to 230°C) and occasional oil splashes. Traditional rubber seals quickly deteriorated, leading to heat loss and costly downtime. Switching to a high-temperature and oil-resistant silicone strip seal (similar to our Gap Solid Silicone Rubber Strip Anti Oil High Temp) extended seal life from 3 months to over 2 years, drastically improving operational efficiency and safety. The product's enhanced resistance to oil was particularly critical here.

- Case Study 4: Marine Environmental Protection

Marine vessels require seals that can withstand constant exposure to saltwater, UV radiation, and varying temperatures. A manufacturer of luxury yachts adopted custom-designed silicone strip seal for all external hatches and windows. The silicone's superior resistance to environmental degradation ensured watertight integrity, prevented corrosion of internal components, and maintained the aesthetic appeal of the vessel over decades, reducing maintenance for yacht owners.

Commitment to Excellence: Trustworthiness and Quality Assurance

Building trust is paramount in the manufacturing industry. A reliable supplier of silicone strip seal products demonstrates this through clear commitments to quality, transparent processes, and robust customer support.

- Certifications & Compliance: Our commitment to quality is underscored by adherence to international standards. Our manufacturing processes are typically certified to ISO 9001, ensuring a consistent and documented quality management system. For relevant applications, our products can meet FDA 21 CFR 177.2600 (for food contact), RoHS, and REACH directives, confirming safety and environmental responsibility. Third-party testing data is often available upon request to verify material properties.

- Rigorous Testing: Every batch of silicone strip seal undergoes comprehensive testing, including durometer hardness, tensile strength, elongation at break, compression set, and specific gravity, conforming to ASTM and ISO standards. For specialized products like `Gap Solid Silicone Rubber Strip Anti Oil High Temp`, additional tests for oil resistance and high-temperature performance are conducted.

- Quality Control Throughout Production: From raw material incoming inspection to in-process checks during extrusion and curing, and finally, a thorough final inspection, quality control is integrated into every stage of manufacturing.

- Warranty & Product Guarantee: We stand behind the quality of our silicone strip seal products, offering comprehensive warranties against manufacturing defects. Specific warranty periods are provided based on product type and application.

- Delivery & Logistics: We understand the importance of timely delivery. Our optimized production and logistics enable reliable lead times, with typical delivery periods varying based on customization level and order volume (e.g., standard profiles: 2-3 weeks; custom tooling: 4-6 weeks for initial samples, then 2-3 weeks for production).

- Customer Support: Our dedicated technical support team is available to assist with material selection, application questions, installation guidance, and any post-purchase inquiries. We aim to be a long-term partner in your success.

Professional FAQ: Your Questions Answered About Silicone Strip Seal

A1: The primary difference lies in their chemical backbone. Silicone is inorganic, based on a silicon-oxygen chain, which gives it superior high and low-temperature flexibility, excellent UV and ozone resistance, and generally better chemical inertness compared to organic rubbers like EPDM (ethylene propylene diene monomer) or Neoprene (polychloroprene), which have carbon-based backbones. While EPDM excels in weather resistance and Neoprene in oil resistance (though less than specialty silicone like our featured product), silicone offers a broader combination of extreme environment performance.

A2: Yes, specific grades of silicone strip seal are manufactured to be inert, non-toxic, and comply with strict regulations such as FDA 21 CFR 177.2600 for food contact and USP Class VI for medical devices. These grades are essential for applications where biocompatibility and cleanliness are paramount.

A3: The ideal hardness (measured in Shore A) depends on the application. Softer silicones (e.g., 20-40 Shore A) are more compressible and conform better to irregular surfaces, ideal for low-closure force seals. Harder silicones (e.g., 60-80 Shore A) offer more structural integrity, better abrasion resistance, and are suited for applications requiring greater mechanical strength or higher compression forces. Consider the mating surface, compression force available, and potential for wear.

A4: Compression set is the permanent deformation of a material after it has been subjected to a compressive load over a period, especially at elevated temperatures. A low compression set indicates that the silicone returns to its original shape effectively after being compressed, maintaining its sealing force and integrity over time. This is critical for long-lasting seals in applications like doors, windows, and industrial equipment where continuous sealing pressure is required.

A5: Standard silicones have limited resistance to certain oils and fuels. However, specialized formulations, like our Gap Solid Silicone Rubber Strip Anti Oil High Temp, are engineered with enhanced additives to significantly improve their resistance to a wide range of oils, fuels, and solvents. It's crucial to specify the types of chemicals the seal will be exposed to when ordering to ensure the correct formulation is used.

A6: The lifespan of a silicone strip seal can vary widely depending on the specific application, environmental conditions (temperature, UV exposure, chemical contact), and the quality of the silicone compound. However, due to silicone's inherent resistance to aging, UV, ozone, and extreme temperatures, silicone seals generally offer an exceptionally long service life, often measured in decades, far surpassing most organic rubbers under similar conditions.

A7: Yes, many silicone strip seal products can be supplied with pressure-sensitive adhesive (PSA) backing. This significantly simplifies installation, eliminating the need for messy glues or mechanical fasteners in many applications. The adhesive type (e.g., acrylic-based, silicone-based) should be chosen based on the application's temperature range and environmental exposure to ensure long-term adhesion.

The Future of Sealing: Innovation and Sustainability in Silicone Strip Seal

The trajectory for silicone strip seal technology is one of continuous innovation, driven by demands for higher performance, greater customization, and enhanced sustainability. Future developments are likely to focus on:

- Smart Materials: Integration of sensors within silicone seals to monitor their condition, temperature, or pressure, enabling predictive maintenance.

- Advanced Formulations: Development of silicone compounds with even greater resistance to extreme chemicals, oils, and abrasive environments, pushing the boundaries of material science.

- Lightweighting Solutions: Creating lighter weight yet equally durable seals for industries like automotive and aerospace, contributing to fuel efficiency.

- Recycling & Circular Economy: Research into more efficient recycling methods for silicone to reduce environmental impact at the end of a product's life cycle.

- Additive Manufacturing: Exploration of 3D printing techniques for highly complex or small-batch custom silicone seals, offering unparalleled design freedom.

These advancements will further cement the position of silicone strip seal as an indispensable component across a multitude of critical applications, contributing to more efficient, safer, and cleaner solutions globally.

References & Further Reading:

- ASTM D2000: Standard Classification System for Rubber Products in Automotive Applications

- ISO 9001: Quality management systems – Requirements

- FDA 21 CFR 177.2600: Rubber Articles Intended for Repeated Use

- The European Silicone Industry: Benefits of Silicones (Illustrative Industry Association)

- Rubber & Plastics News (Illustrative Industry Publication)

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025