High-Performance FKM Rubber Sheet for Industrial Sealing | Silicone Strip Seal

Hebei Qiuzhuo Rubber Products Co.,Ltd. stands at the forefront of rubber sealing and elastomer innovation, specializing in premium fluororubber and silicone sealing solutions. In this comprehensive overview, we will dive deep into the evolving landscape of fkm rubber sheet and silicone strip seal technology, their technical benchmarks, application scenarios, and current industry dynamics. Through detailed charts, case displays, authoritative references, and FAQ, we help engineers, procurement specialists, and industry trend-watchers make informed decisions.

Website: https://www.qzseals.com

Tel: +86 15802108369 | Mobile: +86 18730949119

Email: 1299343081@qq.com

Address: Wangshigong Industrial Zone, Wei County, Xingtai City, Hebei Province

Global Trends and Application Fields of fkm rubber sheet and Silicone Strip Seal

fkm rubber sheet (fluoroelastomer) has become synonymous with high-end industrial sealing, chemical resistance, and durability. Its increasing demand in the chemical processing, automotive, aerospace, electronics, energy, and pharmaceutical sectors reflects a broader shift toward longer service lifespans and enhanced performance under extreme conditions.

Meanwhile, silicone strip seal solutions are widely adopted for their thermal stability, electrical insulation, and outstanding weather resistance. They play critical roles in food-grade manufacturing, medical devices, electric enclosures, and high-temperature gasket applications.

Product Spotlight: Factory Sale Industrial Black Shock Absorbing Epdm

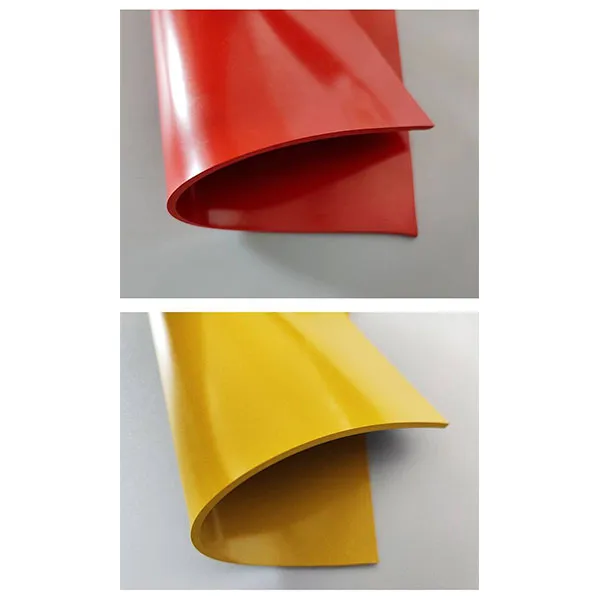

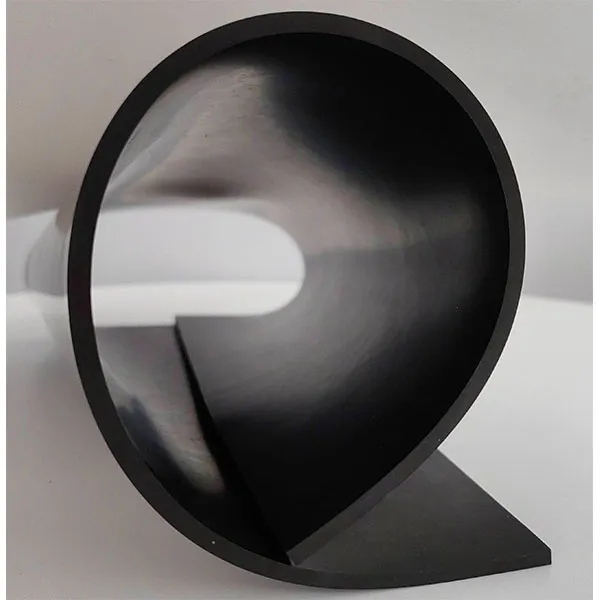

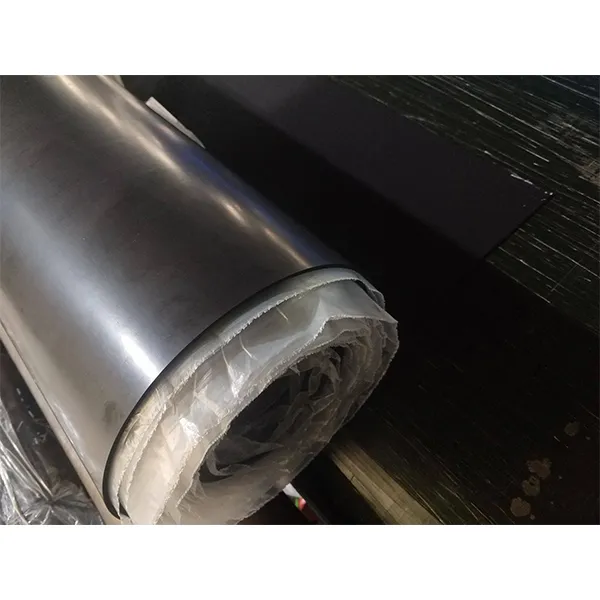

fkm rubber sheet solutions provide exceptional chemical resistance, weathering, and shock absorption—ideal for anti-aging gaskets, industrial mat boards, and custom-molded sealing elements. Factory Sale Industrial Black Shock Absorbing Epdm incorporates premium FKM, NBR, SBR, Neoprene, and EPDM variants, offering a comprehensive custom processing service (moulding, cutting, fabrication to requirements).

- Service temperature: –40°C to +250°C (+300°C short-term peak for FKM)

- Hardness: 60~90 Shore A (customizable)

- Excellent oil, acid, and chemical resistance

- Outstanding elasticity and mechanical strength

- Thickness: 0.5–25mm; Width: up to 1.8m; Length: customizable

- Color: Black (others on request)

- Processing: compression molding, precision die-cutting, CNC trimming

Key Technical Parameters for fkm rubber sheet (Industry Benchmark)

| Parameter | Typical FKM Value | Industry Standard | Notes |

|---|---|---|---|

| Hardness (Shore A) | 70–75 | 65–90 | Customizable via formulation; higher means more rigid |

| Tensile Strength (MPa) | 10–18 | 7–21 | High tensile offers longer service life |

| Elongation at Break (%) | 200–300 | 150–320 | Indicates flexibility under stress |

| Operating Temp (°C) | –40 to +250 | –40 to +230 | Peak up to 300°C for short intervals |

| Compression Set (22h @ 200°C, %) | <35 | <45 | Lower=better resilience |

| Oil Resistance | Excellent | Excellent | Vital in chemical/oil environments |

| Flame Resistance | Self-extinguishing | UL94 V-0/V-1 | For critical fireproof gaskets |

| Weather/Aging Resistance | Superior | Excellent | Ideal for outdoor/UV-intense settings |

Parameter Trend Analysis of fkm rubber sheet (ECharts Visualization)

Factory Sale Industrial Black Shock Absorbing Epdm vs. Similar Rubber Sheet Technologies

Application Scenarios: fkm rubber sheet & Silicone Strip Seal

- Sealing and gasketing for chemical processing equipment, pipelines, storage tanks.

- Automotive, aviation, and marine engine gaskets for oil, fuel, and high temperature exposure.

- High-performance medical device seals (with silicone strip seal for food/biopharma).

- Industrial anti-vibration pads, shock-absorbing mechanisms.

- Electronics, EV battery packs, high-precision waterproof enclosures.

- Outdoor electrical and lighting enclosures — UV/weatherproof seals.

- Building construction, glass facade, and panel joint sealing.

Authoritative Industry Insights & Citations

The International Journal of Adhesion & Adhesives notes: “FKM-based elastomers lead the segment for high-temperature gasket and sealing composites, especially in hybrid and electric vehicle systems.”

Further details on thermal resistance and elastomeric selection standards are reviewed in the ASTM D2000 elastomer classification: “For applications involving sustained contact with aggressive chemicals or high working temperatures, FKM remains the preferred choice.”

Frequently Asked Technical Questions: fkm rubber sheet & Silicone Strip Seal

Q1: What is the primary material composition of an fkm rubber sheet?

A: fkm rubber sheet is primarily composed of fluorinated hydrocarbon polymers (typically polyvinylidene fluoride hexafluoropropylene copolymers) offering exceptional chemical, thermal, and oxidation resistance.Q2: How does an FKM sheet differ from NBR or EPDM in terms of performance?

A: FKM sheets exhibit notably higher chemical and temperature resistance than NBR or EPDM. While NBR excels in oil resistance at moderate temperatures and EPDM in weathering and ozone resistance, FKM can handle both aggressive chemicals and high-operating temperatures up to 250°C with superior lifespan.Q3: Which applications require silicone strip seal over FKM solutions?

A: Silicone strip seal is preferred in high-purity, medical, food processing, and situations with extreme temperature cycling due to its biocompatibility, non-toxicity, and excellent flexibility at low and high temperatures (–60°C to +230°C).Q4: What are the available thickness and surface finish options for your fkm rubber sheet?

A: Standard thicknesses range from 0.5mm to 25mm; surface options include smooth, cloth-impression, and custom-molded textures for advanced grip or sealing interface.Q5: What certifications and testing standards do these sheets comply with?

A: Hebei Qiuzhuo’s fkm rubber sheet and related seal solutions are manufactured in line with ISO 9001, ASTM D2000, REACH, and ROHS environmental compliance. Flame and aging performance testings are available upon request.Q6: How should the fkm rubber sheet be installed for maximal sealing effectiveness?

A: Optimal installation involves clean, dry, even mating surfaces, correct alignment, and use of suitable adhesives (if adhesive-backed), or mechanical fasteners for larger assemblies. Proper torque or clamping pressure ensures leak-free operation.Q7: What are the best practices for storage and handling of fkm rubber sheet and silicone strip seal products?

A: Store in cool, dry, away from direct sunlight and chemical vapors, at 5–25°C; avoid folding or creasing to prevent permanent deformation. Store rolls horizontally or sheets flat.Market Evolution & Future Outlook for fkm rubber sheet & Silicone Strip Seal

- With increased electrification in transport and strict emission standards, FKM sheet consumption in the EV battery, fuel system, and chemical infrastructure sectors rises steeply (Rubber News 2023 report).

- Hybrid materials (FKM/silicone composites) are growing in diversified gasket architectures, combining chemical and thermal resilience (Int. J. Adhesion & Adhesives, 2023).

- Greater demand for precision-die cut, laser-finished seals to fit with IIOT/Smart factory transmission lines.

- Growing environmental awareness is driving the use of greener, halogen-free FKM and silicone chemistries while maintaining superior performance.

Hebei Qiuzhuo Rubber Products Co.,Ltd.

Tel: +86 15802108369 | Mobile: +86 18730949119

Email: 1299343081@qq.com

Wangshigong Industrial Zone, Wei County, Xingtai City, Hebei Province

Official Website: https://www.qzseals.com

- “Global FKM Rubber Market Industry Report, Forecast 2022–2027”, Rubber News

- J.M. Jeon, D. Lee, “Fluoroelastomer Composition and Properties”, International Journal of Adhesion & Adhesives (Elsevier)

- ASTM International, “Standard Classification System for Rubber Products in Automotive Applications”, ASTM D2000

- “Development and Performance of Silicone Rubber Seals”, Journal of Fluorine Chemistry

- “Application of FKM Seals in Next-Generation EV Battery Systems”, SAE International

-

Weather Stripping Door: Enhance Comfort and EfficiencyNewsJul.23,2025

-

The Ultimate Solution for Energy Efficiency: Bottom Seal DoorsNewsJul.23,2025

-

Silicone Seal Strips: Your Solution for a Better SealNewsJul.23,2025

-

Enhance Safety with Anti Slip Stair StripsNewsJul.23,2025

-

Enhance Safety and Aesthetics with Corner Protectors for WallsNewsJul.23,2025

-

Discover the Magic of Silicone Strip Seals for Your GarageNewsJul.23,2025

-

Upgrade Your Seals with Premium Weather StrippingNewsJun.12,2025