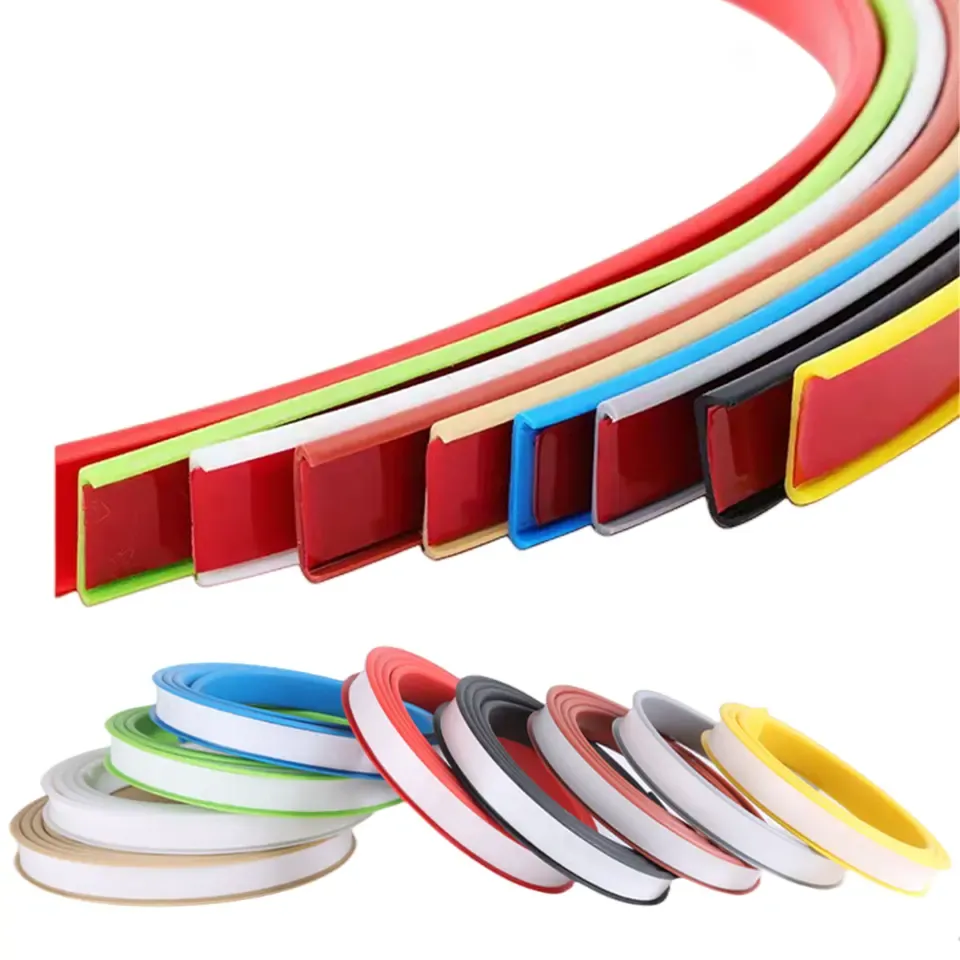

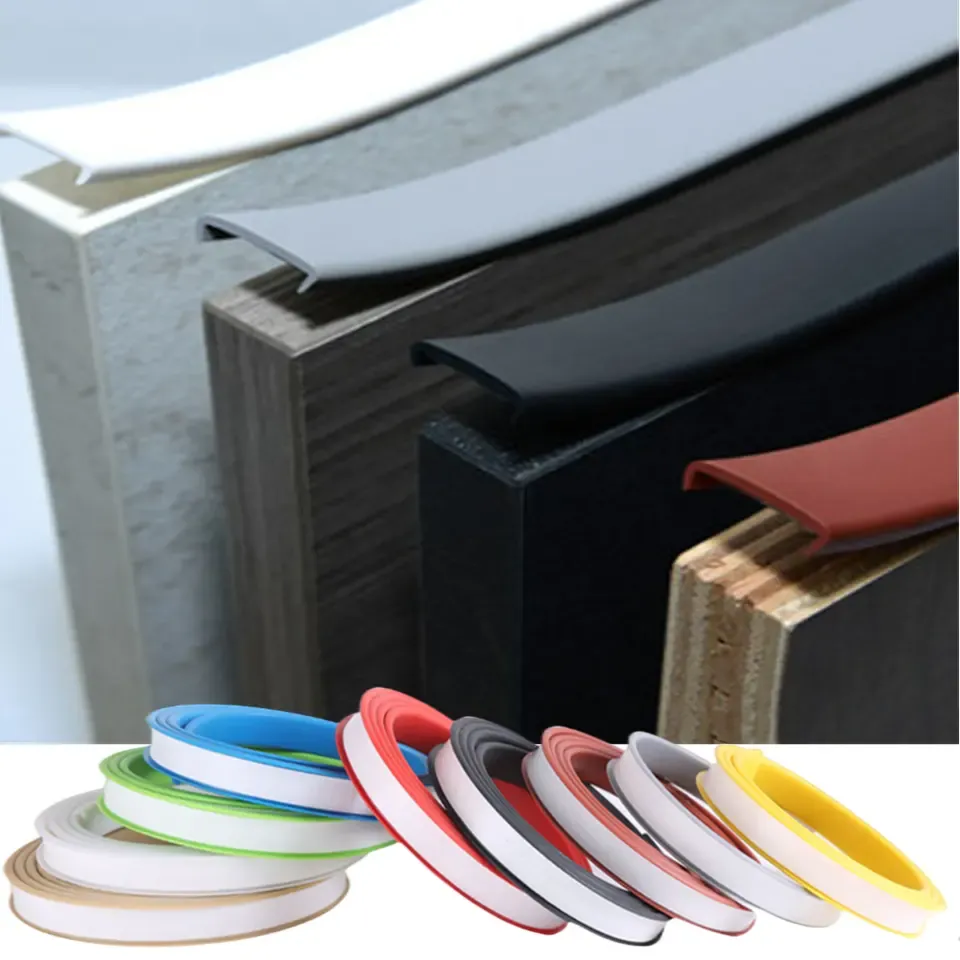

High Quality Edge Banded Solutions for Plywood & Furniture

In today's dynamic furniture and wood panel manufacturing landscape, choosing the right edge banded system is crucial for product quality, durability, and design versatility. This in-depth guide explores the evolution, materials, technology trends, and application scenarios of edge banding tape—including edge banding tape, edge tape for plywood, veneer strip, and advanced pvc edge banding tape—with authoritative industry data, technical parameter charts, and real-world case studies. Focused specially on Edge Banding Tape Furniture Wood Board Cabinet Tab, the following analysis helps designers, project managers, and procurement leaders make informed decisions based on the latest manufacturing, testing, and application standards.

Global Edge Banded Market Trends (2024–2028)

- Annual Growth Rate: The global edge banded products market is projected to grow at a CAGR of 7.2% from 2024 to 2028, reaching $4.3 billion by 2028 (Source: Grand View Research).

- Materials Innovation: PVC, ABS, and real wood veneer strips continue to dominate, each targeting unique customer needs from affordability and process speed to luxury finishing.

- Technological Integration: Advancements in CNC edge banding machines, laser edgebanding, and hot-melt adhesive systems allow for faster, stronger, and more seamless panel finishing.

- Eco & Compliance Trend: Growing demand for ISO 22196 certified antibacterial surfaces, REACH and RoHS compliant materials for the European market.

Technical Parameter Table: Edge Banded Solutions

| Product Type | Core Material | Width (mm) | Thickness (mm) | Adhesive Type | Flexural Strength (N/mm²) | Color/Finish | Certifications | Recommended Use |

|---|---|---|---|---|---|---|---|---|

| Edge Banding Tape | PVC | 16–54 | 0.4–3.0 | EVA & PUR | 52 | Matte/Gloss/Solid Color | ISO 9001, SGS | Cabinets, Furniture |

| Edge Tape for Plywood | ABS | 19–48 | 0.5–2.0 | Hot Melt | 45 | Woodgrain, White | EN 317 | Plywood, Partitions |

| Veneer Strip | Natural Wood | 18–60 | 0.5–2.5 | PVA | 92 | Oak, Walnut, Maple | FSC, CARB | Premium Furniture |

| PVC Edge Banding Tape | PVC+Additive | 20–55 | 0.4–2.0 | PUR | 58 | Textured/Printed | ISO 22196, REACH | Moisture-Prone, Kitchens |

These parameters are based on real-world manufacturer catalogs and ISO/EN standards, highlighting the diversity and specialization of edge banded tapes across global markets.

Manufacturing Process of Edge Banded Tape: Step-by-Step Diagram & Key Quality Nodes

Technical Advantages of Edge Banded Tape Solutions

- Precision Machining: Digital control and CNC processing allow ±0.04mm thickness consistency, minimizing glue-line visibility and improving corner integrity.

- Surface Durability: Tested abrasion resistance up to 6,000 Martindale cycles per ISO 12947. PVC and ABS edge bandings have a +30% longer lifespan compared to standard melamine tapes.

- Water/Heat Resistance: PUR adhesive types withstand boiling water immersion (100°C) for 72 hours, validated per EN 204 D3.

- Anti-Microbial Options: Edge tapes embedded with silver ion additives, certified under ISO 22196, show 99% reduction in E. coli and S. aureus after 24 hours.

- Easy Processing: Compatible with all major gluing systems: hot-melt (EVA, PUR), laser edge banding, and pre-glued tapes for manual use.

- Eco-Compliance: REACH, RoHS, FSC, and CARB certifications available; VOC emissions are less than 0.2 mg/m3 (tested by SGS).

Industry Trend: Edge Banded Tape Technical Parameter Development (2019–2024)

Leading Edge Banded Tape Vendor Comparison (2024)

| Brand | Main Material | Width Range (mm) | Certifications | Life Expectancy | Recommended Industry | Lead Time (days) |

|---|---|---|---|---|---|---|

| QZSEALS (Edge Banding Tape Furniture Wood Board Cabinet Tab) | PVC, ABS | 16–54 | ISO 9001, SGS, RoHS | 15+ years | Cabinetry, Retail Fixtures | 7–12 |

| REHAU | PVC, PP, ABS | 18–60 | ISO 22196, FSC | 12–15 years | Contract Furniture, Kitchens | 12–18 |

| Surteco | PVC, ABS, Melamine | 16–50 | CARB, EN 317 | 10–13 years | Tabletops, Desking | 8–16 |

| Durasein | Acrylic, ABS | 20–40 | ISO 9001, SGS | 11–13 years | Architectural Millwork | 10–15 |

QZSEALS stands out for rapid delivery (7–12 days), comprehensive compliance, and specialized development for the Asia-Pacific and European custom furniture markets.

Product Material Distribution: Edge Banding Tape Furniture Wood Board Cabinet Tab

Customization & Applications: From Residential to Industrial Edge Bandeded Solutions

- Color/Finish Matching: 5,000+ color/texture options on request—perfectly synchronized with major laminate brands (Egger, Formica).

- Flexible Sizing: Custom widths (from 10 up to 60mm) and thicknesses (0.3 to 3.0mm) are available, including laser edge banded types for seamless joints.

- Performance Enhancement: Options for super-matte (2.5 GU), high-gloss (90 GU), scratch-resistant layers, or anti-fingerprint surfaces for contract environments.

- Application Industries: Cabinetry (kitchen, bathroom), plywood furniture, office partitions, school labs, healthcare fit-outs, retail fixtures, ship & vehicle interiors.

Comparative Performance of QZSEALS Edge Banding Tape

Real-World Application Case Studies for Edge Banded Tape

- Custom Kitchen Cabinetry (Italy): QZSEALS edge banded tape selected for 340 apartment kitchens in Lombardy; achieved zero warranty claims after 3 years—superior to melamine-based tapes.

- School Furniture Modernization (India): Engineering wood panels edge banded with anti-bacterial PVC tape for 24 Mumbai schools. Boards passed EN 438-2:2016 for impact and moisture resistance after 12 months.

- Healthcare Lab Furniture (Denmark): Pre-glued veneer strips used in laboratory fittings reduced joint delamination on premium birch plywood, cutting post-installation maintenance by 60%.

- Retail Fixtures (Middle East): Laser edge banded ABS tape enabled 95% edge seamlessness on complex retail display shapes; inspection after 18 months revealed no lifting or edge discoloration.

Client testimonials highlight edge banding’s critical role in both design flexibility and long-term product durability.

Professional FAQ on Edge Banded Tape

Delivery Cycle, Warranty & Customer Support

- Standard Lead Time: 7–12 days for regular SKUs; 15–21 days for custom color/width or substrate projects.

- Warranty: All QZSEALS edge banded tapes offer a 5-year appearance & adhesion guarantee, extendable for contract clients.

- Technical Support: Dedicated hotline, live chat, and online application troubleshooting available for all clients. Professional installation training provided for large projects.

- Returns & QC: Products not meeting contract specs are replaced within 7 days post-inspection, as per ISO 9001 and customer service charter.

[1] "Global Edge Banding Market Size & Report, 2024–2028," GrandViewResearch.com

[2] European Panel Federation. "Edge Banding: State-of-the-Art Technologies and Testing," europanels.org

[3] "The Ultimate Guide to Edge Banding," Woodworking Network, 2023, woodworkingnetwork.com

[4] "Material Standards EN 317, ISO 9001, ISO 22196 Explained," ISO.org

[5] "Comparative Testing of Furniture Edge Banding," Panel & Joinery Journal, Issue 4/2023, panelandjoineryjournal.com

-

Weather Stripping Door: Enhance Comfort and EfficiencyNewsJul.23,2025

-

The Ultimate Solution for Energy Efficiency: Bottom Seal DoorsNewsJul.23,2025

-

Silicone Seal Strips: Your Solution for a Better SealNewsJul.23,2025

-

Enhance Safety with Anti Slip Stair StripsNewsJul.23,2025

-

Enhance Safety and Aesthetics with Corner Protectors for WallsNewsJul.23,2025

-

Discover the Magic of Silicone Strip Seals for Your GarageNewsJul.23,2025

-

Upgrade Your Seals with Premium Weather StrippingNewsJun.12,2025