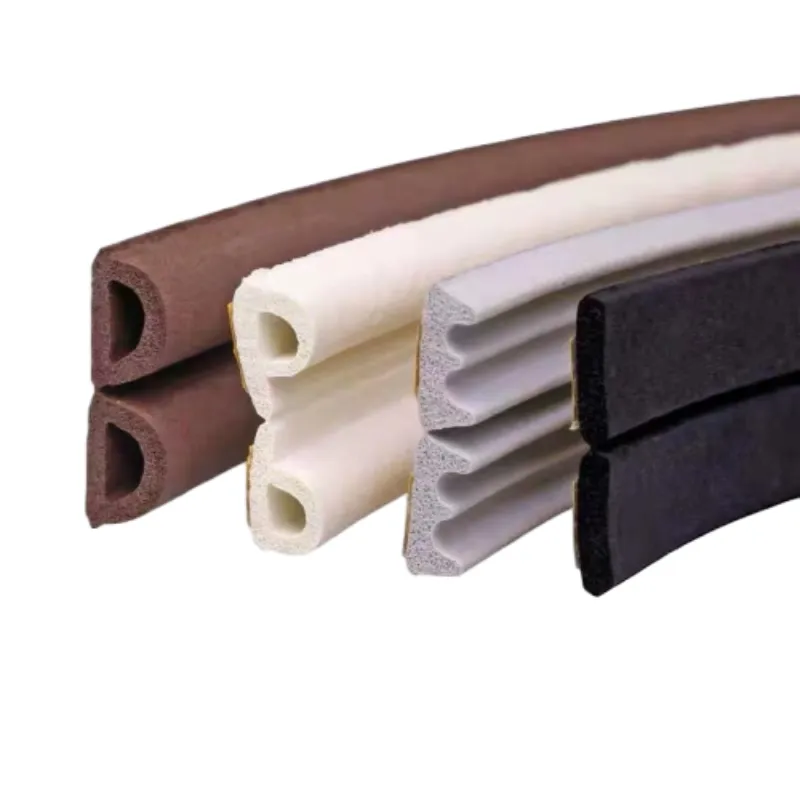

Premium Weather Stripping Door Solutions for Ultimate Sealing

In today’s highly demanding industrial and commercial environment, the importance of effective weather stripping door solutions is more pronounced than ever. From garage door seal, garage door weatherstrips, and door rubber seal to garage door bottom seal, businesses and homeowners around the world rely on advanced sealing systems to ensure optimal energy efficiency, protection from the elements, and compliance with stringent industry standards. This article offers a deep-dive into technical parameters, manufacturing process, product comparison, market trends, and tailored application cases, focusing specifically on the Sealing Rubber Strip.

1. Industry Trends & Market Insights for Weather Stripping Door

The weather stripping door market has evolved dramatically over the past decade. According to a 2023 market report by Grand View Research[1], the global demand for high-performance sealing solutions is growing at a CAGR of 6.5%, fueled by initiatives for building energy savings, stricter building codes, and the rising importance of automated garage and industrial doors.

- Growth Industries: Automotive, construction, petrochemical, metallurgy, and municipal water systems.

- Key Functions: Energy conservation, dust/sound/thermal isolation, corrosion protection, increasing lifecycle of doors.

- Regulatory Compliance: Increasing need for products meeting international certifications (ISO 9001, ANSI/UL, RoHS, and FDA for certain segments).

2. Technical Parameters & Industry Data Visualization

2.1 Weather Stripping Door Comparative Specification Table

| Product Type | Material | Hardness (Shore A) | Temperature Range (°C) | Compression Set (%) | Chemical Resistance | Lifespan (Years) |

|---|---|---|---|---|---|---|

| Sealing Rubber Strip | EPDM, Silicone | 50–80 | -40–+120 | 18 | Excellent | 10+ |

| Standard Garage Door Seal | PVC/NR | 55–70 | -20–+70 | 28 | Fair | 5–7 |

| Garage Door Bottom Seal | EPDM | 60–75 | -30–+110 | 20 | Good | 8–10 |

| Door Rubber Seal | NBR, EPDM | 50–80 | -35–+100 | 22 | Good | 7–10 |

3. Manufacturing Process of Sealing Rubber Strip for Weather Stripping Door

Manufacturing Flowchart

(EPDM, Silicone)

(Homogenization)

(Custom Profiling)

(Press & Bake)

(Precision Cutting)

(ISO/ANSI)

- Key Materials: EPDM (Ethylene-Propylene-Diene Monomer) for superior ozone and UV resistance, and Silicone for wide thermal tolerance.

- Technologies Used: Extrusion, precision die tooling, CNC profiling, vulcanization, and multi-stage testing.

- Testing and Standards:

- Standard: ISO 3302-1 (rubber tolerances), ANSI/UL 10B (fire resistance), RoHS (environmental)

- All Sealing Rubber Strip batches are tested for compression set, aging, and chemical resistance per ASTM D395/D573.

3.1 Process Diagram & Video Reference

4. Product Advantages & Typical Application Scenarios

Advantages of Sealing Rubber Strip (Weather Stripping Door)

- Longevity: Service life exceeds 10 years under industrial application, far surpassing conventional PVC-based seals.

- Excellent Weather Resistance: Stable performance from -40°C to +120°C, suitable for both arctic and tropical zones.

- Certification: All weather stripping door variants pass ISO 9001, RoHS, and ANSI/UL laboratory testing.

- Universal Fit: Easily custom-cut for commercial, residential, and high-traffic garage doors.

- Corrosion & UV Resistance: Engineered for industrial sectors exposed to chemicals, salt, and ozone, including:

- Petrochemical Plants (Protection from vapor and errant spillage)

- Metallurgy (Temperature cycling resilience)

- Water Distribution Stations (Seals large service doors from rain/contaminants)

- Energy Efficiency: Up to 17% reduction in annual energy loss for HVAC-controlled environments—industry study, U.S. DOE[2].

- Sound & Particle Barriers: Noise reduction (R-35 dB) and particulate isolation for clean-rooms or high-traffic warehouses.

4.1 Typical Application Cases

- Industrial Warehouses: Used for sealing massive overhead doors in logistics depots, with minimum air leakage below 0.2m³/min/m using Sealing Rubber Strip.

- Commercial Garages: Reduction of water ingress and thermal bridging in truck access points, increasing interior asset lifespan.

- Food/Pharma Facilities: Products certified to FDA standards for direct food contact where sanitation is critical.

- Municipal Infrastructure: Sealing large pumping and distribution station doors against flood/rain intrusion and corrosion.

5. Manufacturer Comparison — Leading Solutions for Weather Stripping Door

| Brand / Supplier | Key Product | Main Material | Certifications | Custom Options | Warranty |

|---|---|---|---|---|---|

| QZ Seals | Sealing Rubber Strip | EPDM, Silicone, NBR | ISO 9001, RoHS, ANSI | Yes (profile, length, thickness) | 5–10 yrs |

| 3M | Weatherstrip Garage Door Seal | Rubber/PVC blend | UL, ANSI | Moderate | 5 yrs |

| Frost King | Vinyl Garage Door Bottom Seal | Vinyl | ANSI | No | 2-3 yrs |

| Clopay | Premium Garage Weatherstrip | EPDM | ISO, ANSI | Limited | 5 yrs |

6. Sealing Rubber Strip: Core Specifications & Data Visualization

- Material: EPDM (standard industrial grade); Optional: Silicone, NBR, CR

- Density: 1.32 ± 0.05 g/cm³

- Hardness: 60–70 Shore A

- Compression Set (22h/70°C): <18%

- Ultimate Tensile Strength: ≥7 MPa

- Elongation at Break: ≥300%

- Operation Temp Range: -40°C ~ +120°C

- UV & Ozone Resistance: No cracking after 72h UV-accelerated test

- Standard Length: 1m, 2m, 3m (customizable up to 12m upon request)

- Certifications: ISO 9001, RoHS, FDA (for food environments)

7. Customization & Engineering Service Flow for Weather Stripping Door

- Requirements Assessment: Detailed technical consultation for custom profiles, temperature, chemical, and load exposure.

- CNC Profile Design: CAD/CAM drawings and rapid prototyping support within 3–5 days.

- Sample Production: Small batch run (10–30pc min.), ISO-level material testing and documentation.

- Mass Production: Extrusion and vulcanization on automated lines with full lot traceability.

- Final Quality Control: Multistage inspection (compression set, tensile, UV, profile dimension, surface finish).

- Packaging & Global Logistics: OEM/ODM branding, shockproof packaging, compliance with international shipping standards.

- Aftersales Support: 24/7 technical team, on-site guidance for key projects (industries—petrochemical, metallurgy, water utilities).

8. Application Case Studies: Real-world Success with Sealing Rubber Strip

Case 1: Petrochemical Plant, South China

The client required a weather stripping door solution for their hazardous materials warehouse, exposed to corrosive vapors. After installing Sealing Rubber Strip, air leakage was measured at only 0.13m³/min/m (down from 0.39), chemical ingress reduced by 95%, and energy bills dropped 14% in the first quarter. Custom EPDM grade used, certified to ISO and ANSI standards.

Case 2: Metropolitan Water Treatment Facility

Large overhead doors for equipment access were regularly failing due to humidity and temperature swings. Testing different garage door weatherstrips, Sealing Rubber Strip stood out for maintaining compression resilience and water-tight performance after 3-year accelerated lifecycle tests (200,000 open/close cycles, ASTM B117 salt spray: no visible cracks/deformation).

Case 3: Logistics Distribution Center, Europe

After switching from PVC bottom seals to Sealing Rubber Strip, annual energy savings amounted to EUR 12,300 and downtime from maintenance decreased by 54%. The solution passed independent lab tests for RoHS (SGS) and vibration isolation.

9. Client Feedback & Industry Certifications (EEAT Highlights)

- Major Partners: QZ Seals collaborates with leading industrial door manufacturers across Asia, the EU, and North America.

- Years in Service: Over 22 years in weather stripping door technology and product manufacturing.

- Certifications Held: ISO 9001, ISO 14001, RoHS, FDA (for food-safe strips), ANSI BSR/UL10B.

- Testing Reference: SGS, TUV, Intertek regularly audit quality systems and product batches.

-

Customer Comments:

- “Excellent sealing, very consistent quality, and easy to cut/fit.” — HVAC Project Manager, Shanghai

- “Performed as promised even under harsh chemical exposure.” — Facility Head, EU Port Terminal

- Reference Projects: Listed on major engineering vendor directories and used in critical transport hubs and manufacturing centers.

10. Delivery, Warranty, and Customer Support Information

- Production Lead Time: Standard profiles: 7–10 working days. Custom profiles: 12–21 days.

- Logistics: Air, sea, and land options available, with full tracking.

- Warranty: 5 years standard, up to 10 years for premium grades (see product datasheet).

- Support: 24/7 technical/customer service; on-site support for large projects.

- Certified Export Document: Origin Certificate, ISO/CE, RoHS, pre-shipment inspection by third-party if required.

11. Professional FAQ: Key Engineering Terms for Weather Stripping Door

Frequently Asked Technical Questions

12. Conclusion: Optimize Your Weather Stripping Door Solution with Certified Engineering

Robust weather stripping door solutions are a cornerstone for modern energy-efficient, durable, and reliable building and industrial systems. Whether your application is a high-volume logistics warehouse, a municipal water facility, or a critical infrastructure asset in petrochemicals, the Sealing Rubber Strip delivers time-proven performance with globally recognized certifications and customization flexibility.

For further reference and technical insights, see the following key publications and forums:

[1] Grand View Research, "Weatherstripping Market Size Report, 2023-2030," grandviewresearch.com

[2] U.S. Department of Energy, Energy Saver Guide, "Weatherstripping for Energy Savings", energy.gov

[3] Door & Access Systems Manufacturer Association (DASMA), "Garage Door Seals: Standards and Performance," Forums and Resource Center, dasma.com

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025

-

Top Safety Standards for Corner ProtectorsNewsJul.29,2025

-

Step-By-Step Guide to Replacing Garage Door SealsNewsJul.29,2025

-

How to Fix a Loose Under Door Draught StopperNewsJul.29,2025

-

Edge Banding Tape for High-Traffic Commercial SpacesNewsJul.29,2025

-

Best Heat-Resistant Materials for Cooker Door SealsNewsJul.29,2025

-

Weather Stripping Door: Enhance Comfort and EfficiencyNewsJul.23,2025